Are you gearing up for an interview for a Foamite Mixer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Foamite Mixer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

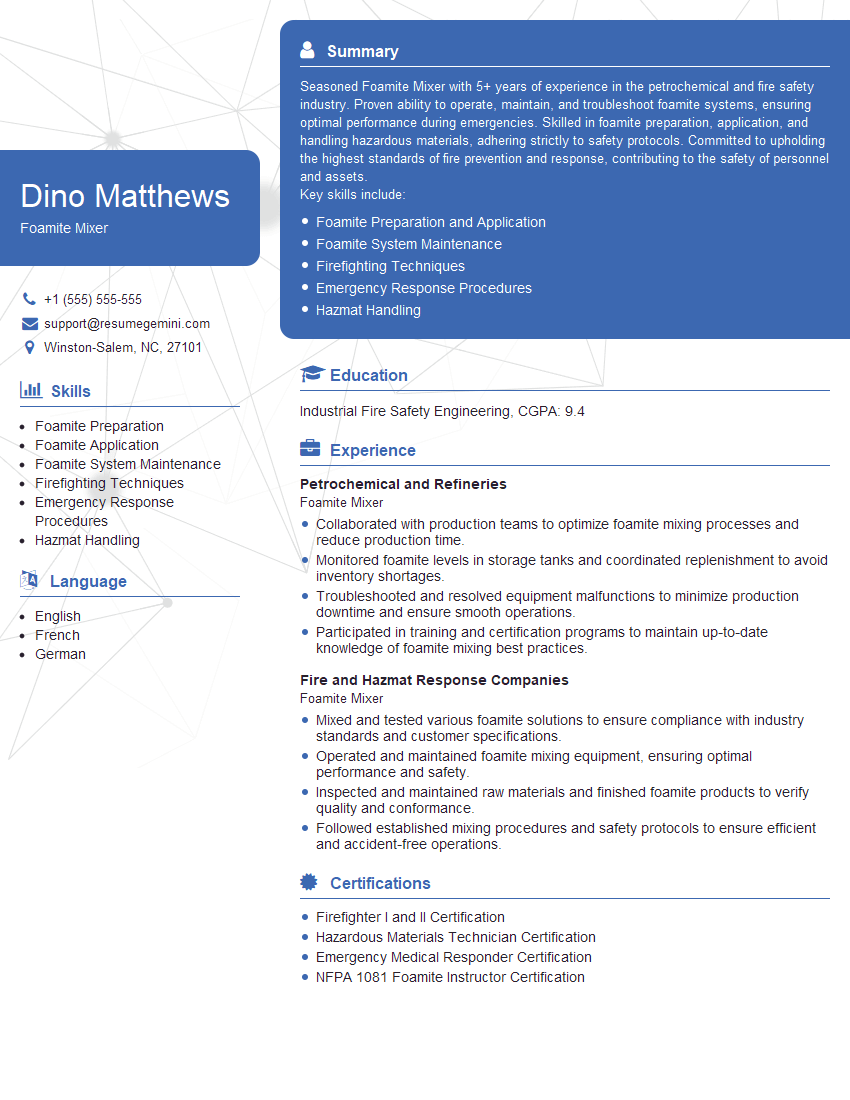

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foamite Mixer

1. What are the key steps involved in the foamite mixing process?

- Calculate the required amount of foamite concentrate and water based on the desired foam expansion ratio.

- Add the foamite concentrate to the water source and mix thoroughly using a specialized foamite mixer.

- Ensure the foamite solution is homogeneous and free of lumps or undissolved concentrate.

- Transfer the mixed foamite solution to the storage tank or the fire fighting equipment.

2. What types of foamite mixing equipment are commonly used?

Mechanical Foamite Mixers

- In-line mixers installed within the fire suppression system

- Portable mixers used for manual mixing in small batches

Venturi Foamite Mixers

- Creates foamite solution by injecting foamite concentrate into a high-velocity water stream

- Produces a fine, uniform foam

3. What factors can affect the quality of the foamite solution?

- Accuracy of foamite concentrate and water measurements

- Mixing time and intensity

- Water temperature and quality

- Type and performance of the foamite mixer

4. What maintenance procedures are necessary for foamite mixers?

- Regular cleaning of the mixer to prevent buildup of foamite residue

- Inspection and replacement of worn or damaged components

- Lubrication of moving parts as per manufacturer’s specifications

- Calibration of the mixer to ensure accurate mixing ratios

5. What safety precautions should be taken when handling foamite concentrates?

- Wear appropriate personal protective equipment (PPE) including gloves, goggles, and respiratory mask

- Avoid contact with skin and eyes

- Store foamite concentrates in a well-ventilated area

- Follow proper disposal procedures for foamite and contaminated materials

6. How do you determine the appropriate foam expansion ratio for a given application?

- Consider the type of fuel or hazard being protected

- Refer to manufacturer’s specifications or industry standards

- Account for environmental factors such as wind speed and temperature

- Perform field tests to optimize the foam expansion ratio

7. What is the difference between Class A and Class B foam concentrates?

- Class A foam concentrates are designed to extinguish fires involving ordinary combustible materials such as wood, paper, and textiles.

- Class B foam concentrates are formulated to create a vapor-suppressing foam blanket over flammable liquids, such as gasoline, oil, and solvents.

8. What are the advantages of using foam firefighting systems?

- Excellent flame knockdown and extinguishment capabilities

- Forms a protective blanket over the fuel, preventing re-ignition

- Cools and smothers the fire, reducing heat and smoke

- Can be used in both indoor and outdoor applications

9. What are the limitations of foam firefighting systems?

- Not effective on fires involving polar solvents

- Can be affected by strong winds

- Can be challenging to apply in confined spaces

- Requires proper mixing and application to be effective

10. How do you ensure the effectiveness of foam firefighting systems?

- Regular testing and maintenance of foamite mixers and firefighting equipment

- Training of personnel on proper foam application techniques

- Adhering to industry standards and best practices

- Continuous evaluation and improvement of foam firefighting systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foamite Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foamite Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Foamite Mixer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Foamite Mixer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.