Are you gearing up for an interview for a Foiling Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Foiling Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

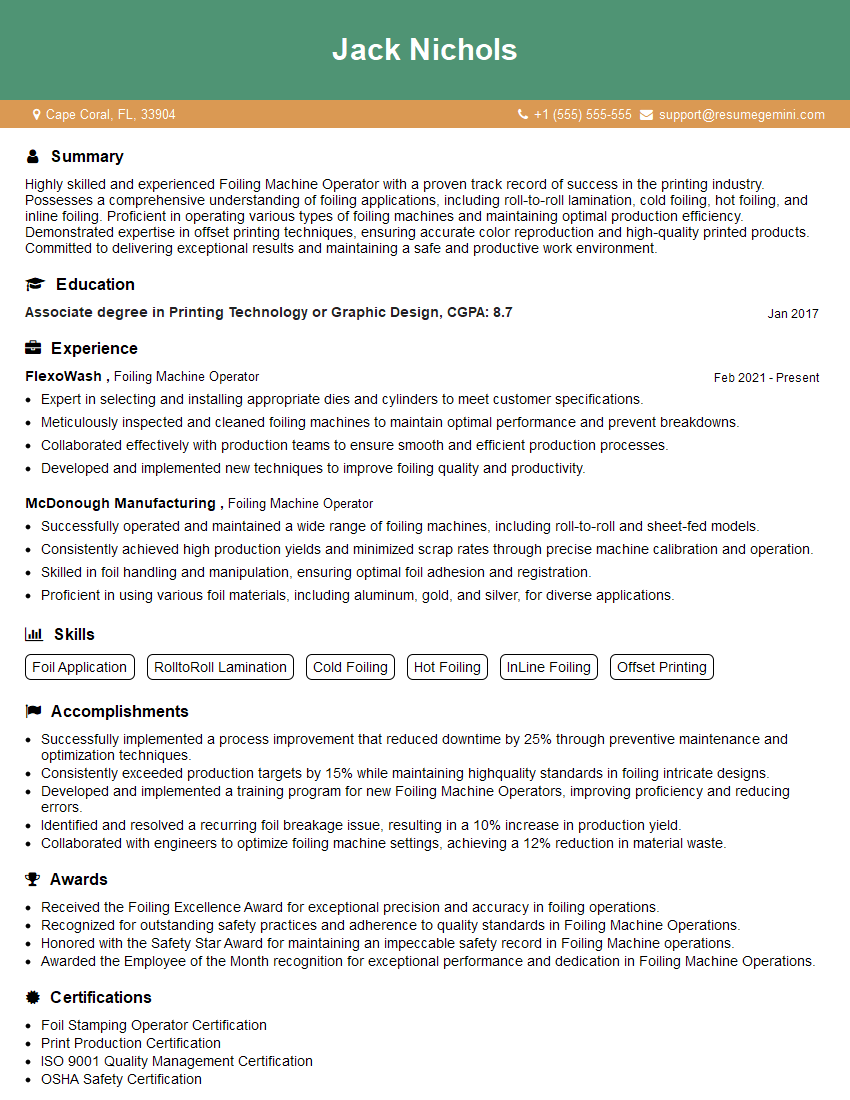

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foiling Machine Operator

1. What are the key responsibilities of a Foiling Machine Operator?

The key responsibilities of a Foiling Machine Operator include:

- Operating and maintaining foiling machines to apply foil to various materials, such as paper, plastic, and metal.

- Setting up and adjusting machine parameters, such as temperature, pressure, and speed, to ensure optimal foiling results.

- Monitoring the foiling process to identify and resolve any issues.

- Inspecting foiled materials to ensure quality standards are met.

- Performing routine maintenance on foiling machines, including cleaning, lubrication, and minor repairs.

2. What are the steps involved in operating a foiling machine?

The steps involved in operating a foiling machine typically include:

Preparing the machine:

- Inspecting the machine for any damage or wear.

- Cleaning the machine and its components.

- Lubricating moving parts.

- Installing the appropriate foil roll.

Setting up the machine:

- Adjusting machine parameters, such as temperature, pressure, and speed, according to the material being foiled.

- Loading the material to be foiled into the machine.

Operating the machine:

- Starting the machine and monitoring the foiling process.

- Making adjustments to machine parameters as needed to ensure optimal foiling results.

- Inspecting foiled materials to ensure quality standards are met.

Shutting down the machine:

- Stopping the machine and allowing it to cool down.

- Cleaning the machine and its components.

- Storing the foil roll properly.

3. What are the different types of foiling machines, and what are their key features?

There are various types of foiling machines available, each with its own unique features and applications.

Flatbed foiling machines:

- Suitable for foiling flat materials, such as paper, cardboard, and plastic.

- Feature a flat bed where the material is placed, and the foil is applied using a heated roller.

Rotary foiling machines:

- Designed for foiling cylindrical or conical objects, such as bottles, cans, and tubes.

- Utilize a rotating drum to apply foil to the surface of the object.

Digital foiling machines:

- Employs digital technology to apply foil to specific areas of a material.

- Offers precise and intricate foiling capabilities.

4. How do you ensure the quality of foiled materials?

Ensuring the quality of foiled materials involves:

- Inspecting the material before foiling to identify any defects or inconsistencies.

- Calibrating and maintaining the foiling machine regularly to ensure accurate and consistent foiling results.

- Monitoring the foiling process and making adjustments as needed to optimize foil adhesion and appearance.

- Inspecting foiled materials after the process to identify any defects or non-conformities.

- Maintaining detailed records of foiling parameters and quality control checks.

5. What are the common challenges faced by Foiling Machine Operators, and how do you overcome them?

Common challenges faced by Foiling Machine Operators include:

Foil tearing or wrinkling:

- Caused by improper machine settings, material tension, or foil quality.

- Can be overcome by adjusting machine parameters, using higher-quality foil, or modifying the material handling process.

Foil blistering or delamination:

- Occurs when the foil does not adhere properly to the material.

- Can be prevented by ensuring proper surface preparation, using the correct foil adhesive, and applying the foil at the optimal temperature and pressure.

Foil color fading or discoloration:

- Caused by exposure to UV light, heat, or chemicals.

- Can be minimized by using UV-resistant foil, protecting foiled materials from excessive heat and sunlight, and avoiding contact with harsh chemicals.

6. How do you maintain and troubleshoot foiling machines?

Maintaining and troubleshooting foiling machines involve:

Preventive maintenance:

- Regularly cleaning and lubricating the machine.

- Inspecting and replacing worn or damaged parts.

- Calibrating the machine according to the manufacturer’s specifications.

Troubleshooting:

- Identifying the source of the problem through observation and diagnostic tests.

- Consulting technical manuals or seeking assistance from the machine manufacturer.

- Repairing or replacing faulty components.

- Performing test runs to ensure the machine is functioning correctly.

7. How do you stay updated with the latest advancements in foiling technology?

To stay updated with the latest advancements in foiling technology:

- Attending industry conferences and exhibitions.

- Reading trade publications and technical articles.

- Consulting with equipment manufacturers and suppliers.

- Participating in online forums and discussion groups dedicated to foiling.

8. What are the safety precautions that should be followed when operating foiling machines?

Important safety precautions when operating foiling machines include:

- Wearing appropriate personal protective equipment, such as safety glasses, gloves, and earplugs.

- Ensuring proper ventilation to avoid exposure to fumes and dust.

- Keeping the work area clean and free of clutter.

- Following lockout/tagout procedures before performing maintenance or repairs.

- Being aware of potential hazards, such as moving parts, hot surfaces, and sharp edges.

9. How do you handle production deadlines and ensure timely delivery of foiled products?

To handle production deadlines and ensure timely delivery of foiled products:

- Planning and prioritizing work orders based on their due dates.

- Estimating production times accurately and communicating them clearly to clients.

- Monitoring the progress of production and identifying any potential bottlenecks.

- Communicating regularly with clients to keep them informed of order status.

- Exploring alternative solutions or outsourcing certain tasks if necessary to meet deadlines.

10. Why are you interested in working as a Foiling Machine Operator in our company?

I am interested in working as a Foiling Machine Operator in your esteemed company because:

- Your company is a renowned leader in the industry, and I am eager to contribute my skills to your team.

- I am highly proficient in operating and maintaining foiling machines, and I have a proven track record of producing high-quality foiled products.

- I am passionate about foiling and am constantly seeking opportunities to enhance my knowledge and expertise in this field.

- I am a highly motivated and results-oriented individual with a strong work ethic and attention to detail.

- I am confident that I can make a significant contribution to your company and help you achieve your business objectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foiling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foiling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Foiling Machine Operator is responsible for operating and maintaining a foiling machine, which is used to apply a thin layer of metal foil to paper or other materials. The key job responsibilities of a Foiling Machine Operator include:

1. Operating the Foiling Machine

Foiling Machine Operators are responsible for operating the foiling machine, which is used to apply a thin layer of metal foil to paper or other materials. This involves setting up the machine, loading the paper or other material, and starting the machine. The operator must also monitor the machine’s operation and make adjustments as needed.

- Set up and operate the foiling machine according to established procedures.

- Load and unload paper or other materials onto the machine.

- Monitor the machine’s operation and make adjustments as needed.

2. Maintaining the Foiling Machine

Foiling Machine Operators are also responsible for maintaining the foiling machine. This involves cleaning the machine, lubricating the moving parts, and making minor repairs. The operator must also keep a log of all maintenance activities.

- Clean the machine on a regular basis.

- Lubricate the moving parts of the machine.

- Make minor repairs to the machine.

- Keep a log of all maintenance activities.

3. Inspecting the Foiled Product

Foiling Machine Operators are responsible for inspecting the foiled product. This involves checking the product for defects, such as wrinkles, tears, or smudges. The operator must also check the product to ensure that it meets the customer’s specifications.

- Inspect the foiled product for defects.

- Check the product to ensure that it meets the customer’s specifications.

- Reject any product that does not meet the customer’s specifications.

4. Other Duties

Foiling Machine Operators may also be responsible for other duties, such as:

- Assisting with the loading and unloading of materials.

- Maintaining a clean and organized work area.

- Following all safety procedures.

Interview Tips

To ace an interview for a Foiling Machine Operator position, candidates should be prepared to discuss their experience operating and maintaining foiling machines. They should also be able to demonstrate their knowledge of the industry and their commitment to safety. Here are some interview tips:

1. Prepare for the Interview

Before the interview, candidates should take some time to prepare. This includes researching the company, the position, and the industry. Candidates should also practice answering common interview questions.

- Research the company, the position, and the industry.

- Practice answering common interview questions.

- Dress professionally and arrive on time for the interview.

2. Be Enthusiastic and Positive

Candidates should be enthusiastic and positive during the interview. They should be able to convey their passion for the industry and their commitment to safety. Candidates should also be able to highlight their skills and experience.

- Be enthusiastic and positive during the interview.

- Convey your passion for the industry and your commitment to safety.

- Highlight your skills and experience.

3. Answer Questions Honestly and Clearly

Candidates should answer questions honestly and clearly. They should be able to provide specific examples of their experience and skills. Candidates should also be prepared to discuss their strengths and weaknesses.

- Answer questions honestly and clearly.

- Provide specific examples of your experience and skills.

- Be prepared to discuss your strengths and weaknesses.

4. Ask Questions

At the end of the interview, candidates should ask questions. This shows that they are interested in the position and the company. Candidates should also ask questions that will help them learn more about the company and the position.

- Ask questions at the end of the interview.

- This shows that you are interested in the position and the company.

- Ask questions that will help you learn more about the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Foiling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!