Are you gearing up for an interview for a Food Processing Chemist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Food Processing Chemist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

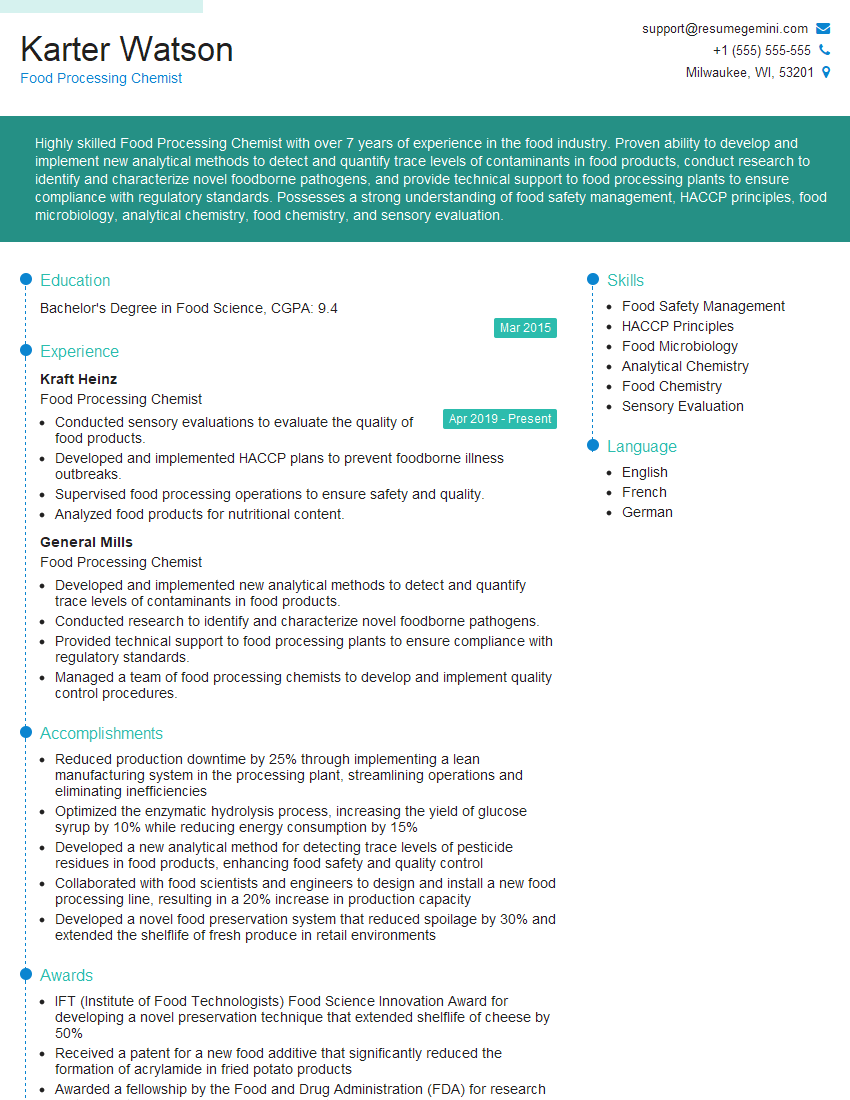

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Food Processing Chemist

1. Describe the role of pH in food processing and provide examples of how it affects food quality and safety.

pH is a crucial parameter in food processing as it influences various aspects of food quality and safety:

- Microbial growth: pH plays a significant role in controlling microbial growth. Most bacteria prefer a pH range of 6.5 to 7.5, while yeasts and molds can tolerate more acidic conditions. By adjusting pH, food processors can inhibit the growth of spoilage and pathogenic microorganisms.

- Enzymatic activity: pH also affects the activity of enzymes involved in food processing and preservation. For example, pectinases, used in fruit juice clarification, are most active in acidic conditions, while proteases, used in meat tenderization, are more effective at neutral to slightly alkaline pH.

- Color and flavor: pH can influence the color and flavor of foods. Acidic conditions can enhance the color of fruits and vegetables, while alkaline conditions may promote browning reactions. pH also affects the solubility and release of flavor compounds, impacting the overall taste of food products.

2. Discuss the principles and methods used for food preservation, including both traditional and modern techniques.

Traditional Techniques

- Drying: Removes moisture to inhibit microbial growth, e.g., sun-drying fruits, vegetables.

- Salting: Draws out moisture and creates an osmotic environment unfavorable for bacteria, e.g., salted fish, cured meats.

- Smoking: Imparts flavor and antimicrobial compounds, e.g., smoked salmon, bacon.

Modern Techniques

- Thermal processing: Uses heat to kill microorganisms, e.g., canning, pasteurization.

- Freezing: Lowers temperature to inhibit microbial growth and enzyme activity, e.g., frozen fruits, vegetables.

- Irradiation: Exposes food to ionizing radiation to kill microorganisms and slow down ripening, e.g., irradiated spices.

3. Explain how food processing can impact the nutritional value of food. Give examples.

- Loss of vitamins: Heat and light can degrade vitamins, particularly water-soluble vitamins like vitamin C and B vitamins, e.g., boiling vegetables can result in vitamin C loss.

- Protein denaturation: High temperatures can denature proteins, altering their structure and functionality, e.g., overcooking meat can reduce its nutritional value.

- Enhanced bioavailability: Some processing techniques can improve the bioavailability of nutrients, e.g., cooking carrots increases the absorption of beta-carotene.

- Fortification: Food processing can be used to add nutrients to foods, e.g., adding vitamin D to milk.

4. Describe the role of food additives in food processing and their potential implications for food safety.

- Preservatives: Extend shelf life by inhibiting microbial growth, but some may have potential health concerns, e.g., sulfites.

- Antioxidants: Prevent oxidation and rancidity, but excessive intake may interfere with nutrient absorption, e.g., butylated hydroxyanisole (BHA).

- Emulsifiers: Keep ingredients mixed, but some may be derived from allergenic sources, e.g., soy lecithin.

- Artificial sweeteners: Provide sweetness without the calories of sugar, but excessive consumption may have metabolic effects, e.g., aspartame.

5. Discuss the challenges and opportunities in the field of food processing chemistry.

Challenges

- Consumer demands: Meeting evolving consumer preferences for healthier, more sustainable, and personalized food products.

- Food safety regulations: Complying with increasingly stringent food safety standards to ensure public health.

- Environmental sustainability: Minimizing environmental impact through efficient processes and waste reduction.

Opportunities

- Emerging technologies: Leveraging advancements in food science and technology to develop innovative and nutritious products.

- Personalized nutrition: Creating tailored food products based on individual health and dietary needs.

- Food waste reduction: Developing sustainable solutions to minimize food loss and waste throughout the supply chain.

6. Explain the difference between aseptic and non-aseptic food processing.

- Aseptic processing: Sterilizes the product and packaging separately and then fills the sterile product into sterile containers in a sterile environment, ensuring a shelf-stable product without refrigeration.

- Non-aseptic processing: Sterilizes the product but not the packaging; the product is then filled into non-sterile containers, requiring refrigeration to prevent microbial spoilage.

7. Describe the principles and applications of extrusion in food processing.

- Principles: A mixture of ingredients is heated, pressurized, and forced through a die to create a continuous product with a specific shape.

- Applications: Production of pasta, cereals, snacks, pet food, and meat substitutes.

8. Discuss the importance of quality control in food processing and outline some key quality control measures.

- Ensures food safety: Detecting and preventing contamination with pathogens or harmful substances.

- Maintains product consistency: Meeting specifications for appearance, nutritional content, and sensory attributes.

- Protects brand reputation: Avoiding product recalls and maintaining consumer trust.

- Key measures: Raw material inspection, process monitoring, finished product testing, traceability systems.

9. Explain the concept of mass balance in food processing and its significance in process optimization.

- Definition: Accounting for all inputs and outputs in a food processing system to ensure that nothing is lost or unaccounted for.

- Significance: Identifying inefficiencies, optimizing resource utilization, and reducing waste.

10. Describe the role of enzymes in food processing and provide examples of their applications.

- Act as catalysts: Accelerate chemical reactions without being consumed.

- Applications: Meat tenderization (proteases), fruit juice clarification (pectinases), dairy processing (lactase).

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Food Processing Chemist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Food Processing Chemist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Food Processing Chemists play a crucial role in ensuring the safety, quality, and nutritional value of food products. Their responsibilities encompass a wide range of tasks, including:

1. Research and Development

Conducting research to develop new food processing techniques, improve existing ones, and enhance product quality.

- Identifying and evaluating new ingredients, additives, and packaging materials.

- Developing and optimizing food preservation methods to extend shelf life and maintain product safety.

2. Quality Control

Ensuring that food products meet industry standards and regulatory requirements by:

- Performing chemical and microbiological analyses on raw materials, ingredients, and finished products.

- Monitoring production processes to identify and mitigate potential quality issues.

- Working closely with quality assurance personnel to establish and implement HACCP plans.

3. Troubleshooting

Investigating and resolving quality and safety issues that arise during food production:

- Analyzing product samples to identify the root cause of problems.

- Developing and implementing corrective actions to prevent recurrence.

- Working with production and engineering teams to implement process modifications and improvements.

4. Regulatory Compliance

Ensuring that food processing operations comply with relevant laws and regulations, including:

- Monitoring industry trends and regulatory changes.

- Maintaining accurate records of food processing activities.

- Working with regulatory agencies to ensure compliance and address concerns.

Interview Tips

To ace an interview for a Food Processing Chemist position, candidates should thoroughly prepare and showcase their skills, knowledge, and experience. Here are some interview tips:

1. Research the Company and Role

Research the company and industry thoroughly. This will help you tailor your answers, demonstrate your interest, and ask informed questions during the interview.

2. Review Key Concepts and Technologies

Review fundamental chemistry concepts, food processing techniques, and quality control principles. Be familiar with industry-specific technologies and innovations.

3. Highlight Your Skills and Experience

Emphasize your technical skills, such as analytical chemistry, microbiology, and process optimization. Highlight your experience in food safety, quality control, and troubleshooting.

Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your accomplishments.

4. Practice Answering Common Interview Questions

Prepare for common interview questions, such as why you are interested in the role, your strengths and weaknesses, and your career goals. Practice delivering concise and compelling answers.

5. Ask Thoughtful Questions

Asking thoughtful questions during the interview demonstrates your engagement and interest. Inquire about the company’s culture, sustainability initiatives, or opportunities for professional development.

Example Outline:

Can you describe the day-to-day responsibilities of a Food Processing Chemist in your organization?

What are the key challenges and opportunities facing the food processing industry?

How does your company prioritize food safety and quality?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Food Processing Chemist interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.