Feeling lost in a sea of interview questions? Landed that dream interview for Food Processing Plant Manager but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Food Processing Plant Manager interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

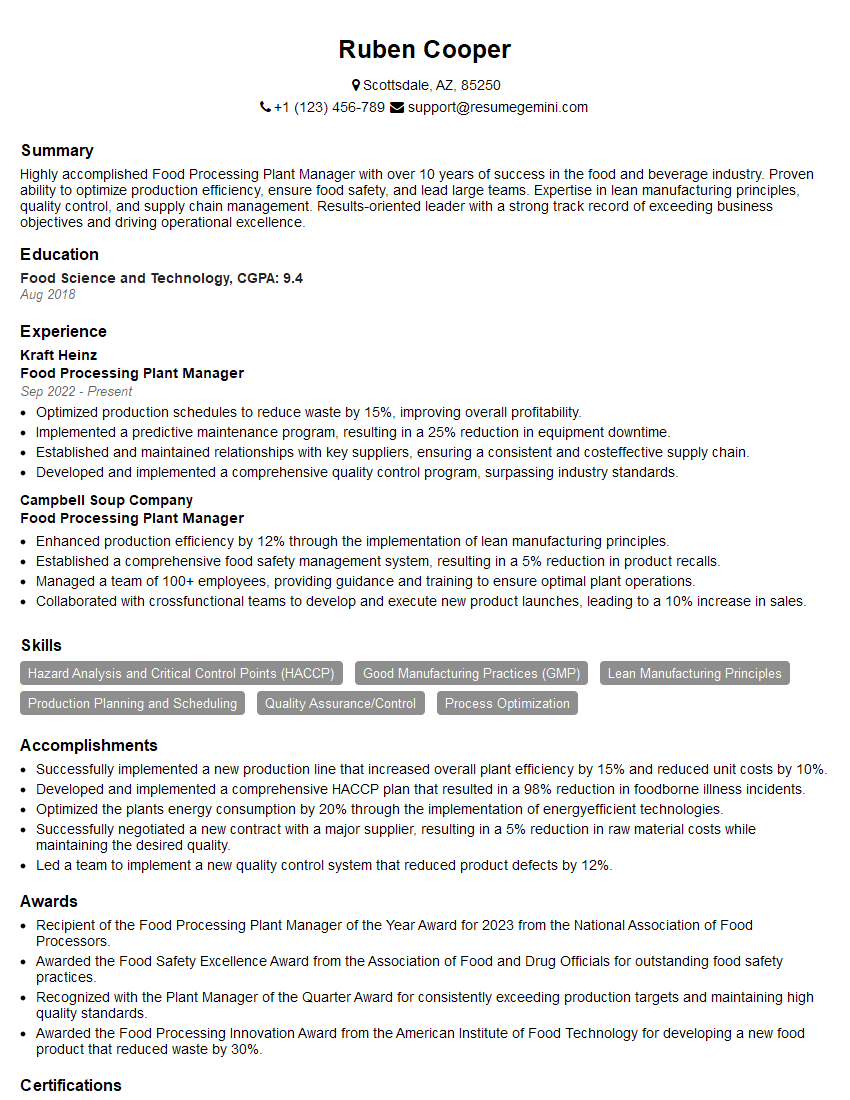

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Food Processing Plant Manager

1. How would you ensure that the food processing plant complies with all relevant food safety regulations and standards?

To ensure compliance with food safety regulations and standards, I would implement the following strategies:

- Regularly review and update the plant’s food safety plan to align with industry best practices and regulatory requirements.

- Establish a comprehensive food safety training program for all employees, covering food handling, hygiene, and sanitation practices.

- Conduct periodic internal audits to identify and address any potential risks or non-conformances.

- Partner with external auditors to conduct independent assessments and provide objective feedback on the plant’s food safety performance.

- Maintain open communication with regulatory agencies to stay informed about changes in regulations and to promptly address any concerns raised.

2. How do you approach the management of food waste and by-products in a food processing plant?

Waste Reduction and Minimization

- Implement lean manufacturing principles to optimize processes and reduce waste.

- Explore innovative technologies and equipment to enhance resource efficiency.

- Train employees on waste reduction techniques and encourage their participation in waste management initiatives.

By-Product Utilization

- Identify potential uses for by-products, such as animal feed, fertilizer, or bioenergy production.

- Partner with external organizations or companies to repurpose or sell by-products.

- Explore innovative technologies that can convert by-products into valuable resources.

3. Describe your experience in implementing and maintaining a quality control system in a food processing plant.

In my previous role, I established and managed a comprehensive quality control system that ensured the production of high-quality food products.

- Developed and implemented quality control procedures covering all aspects of production, from raw material inspection to finished product release.

- Established a rigorous testing regime to monitor critical control points and ensure compliance with established specifications.

- Trained and supervised a team of quality control inspectors to ensure consistent adherence to quality standards.

- Analyzed quality data to identify trends and areas for improvement, and implemented corrective actions as needed.

- Regularly reviewed and updated the quality control system to maintain its effectiveness and alignment with industry best practices.

4. How do you ensure the efficient and timely production of high-quality food products while adhering to production schedules?

To ensure efficient and timely production of high-quality food products while adhering to production schedules, I would focus on the following strategies:

- Optimize production processes through lean manufacturing principles, reducing waste and increasing productivity.

- Implement a robust planning and scheduling system to coordinate production activities, minimize downtime, and meet delivery deadlines.

- Empower production team leaders to make decisions and resolve issues, fostering a sense of ownership and accountability.

- Invest in employee training and development to enhance skills and knowledge, enabling them to perform their tasks effectively and efficiently.

- Establish clear communication channels to facilitate information sharing, coordination, and problem-solving among production teams.

5. How do you manage and maintain the equipment and machinery in a food processing plant to ensure optimal performance and minimize downtime?

To manage and maintain equipment and machinery in a food processing plant, I would implement the following measures:

- Establish a preventive maintenance program to regularly inspect, service, and repair equipment.

- Implement a computerized maintenance management system (CMMS) to track maintenance activities, identify potential issues, and schedule repairs.

- Train maintenance technicians to ensure they are proficient in operating and maintaining all equipment.

- Maintain an inventory of spare parts and consumables to minimize downtime in the event of equipment failures.

- Establish clear procedures for reporting and responding to equipment malfunctions, ensuring prompt resolution.

6. How do you ensure the safety and well-being of employees in a food processing plant?

To ensure the safety and well-being of employees in a food processing plant, I would prioritize the following measures:

- Establish and implement comprehensive safety protocols, including training, regular safety inspections, and emergency response plans.

- Provide personal protective equipment (PPE) to employees and ensure proper usage and maintenance.

- Promote a culture of safety awareness and encourage employees to report potential hazards and unsafe practices.

- Regularly assess and evaluate potential risks in the workplace and implement mitigation strategies to minimize accidents and injuries.

- Conduct safety drills and exercises to prepare employees for emergency situations and ensure effective response.

7. How do you manage and motivate a team of employees in a food processing plant?

To manage and motivate a team of employees in a food processing plant, I would adopt the following approaches:

- Foster a positive and inclusive work environment that values employee contributions.

- Set clear goals and expectations, and provide regular feedback to employees on their performance.

- Recognize and reward employee achievements, both individually and as a team.

- Empower employees to make decisions and take ownership of their work.

- Encourage open communication and address concerns or issues promptly.

8. How do you stay up-to-date with the latest advancements in food processing technology and best practices?

To stay up-to-date with the latest advancements in food processing technology and best practices, I would:

- Attend industry conferences, workshops, and trade shows.

- Read technical journals and research papers.

- Network with other food processing professionals.

- Explore new technologies and innovations through collaborations with academia and technology providers.

- Participate in industry associations and working groups.

9. How do you handle customer complaints and ensure customer satisfaction in a food processing plant?

To handle customer complaints and ensure customer satisfaction, I would:

- Establish a robust customer complaint handling system.

- Train employees on complaint resolution techniques.

- Investigate complaints promptly and thoroughly to identify the root cause.

- Provide timely and effective resolutions to customers.

- Follow up with customers to ensure their satisfaction and prevent recurrence of issues.

10. How do you manage the financial aspects of a food processing plant, including budgeting, cost control, and profitability analysis?

To manage the financial aspects of a food processing plant, I would:

- Develop and manage the plant’s budget.

- Implement cost control measures to optimize expenses.

- Monitor and analyze financial performance to identify areas for improvement.

- Prepare financial reports for stakeholders.

- Collaborate with finance professionals to ensure alignment with the company’s financial objectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Food Processing Plant Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Food Processing Plant Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Food Processing Plant Manager, you will be responsible for the overall operations of a food processing plant. This includes ensuring that the plant is operating efficiently and safely, meeting production targets, and maintaining high-quality standards.

1. Production Management

You will be responsible for overseeing all aspects of production, from planning and scheduling to quality control and packaging. You will also be responsible for managing a team of production workers and ensuring that they are trained and motivated.

- Plan and schedule production activities to meet customer demand

- Monitor production processes and make adjustments as needed

- Ensure that all products meet quality standards

- Manage a team of production workers

2. Quality Assurance

You will be responsible for developing and implementing quality assurance programs to ensure that all products meet safety and quality standards.

- Develop and implement quality assurance programs

- Monitor food safety and sanitation practices

- Conduct regular inspections of the plant and equipment

- Investigate and resolve quality issues

3. Safety Management

You will be responsible for ensuring that the plant is safe for employees and visitors. This includes developing and implementing safety programs, conducting safety training, and investigating accidents.

- Develop and implement safety programs

- Conduct safety training for employees

- Investigate accidents and implement corrective actions

- Monitor compliance with safety regulations

4. Regulatory Compliance

You will be responsible for ensuring that the plant is in compliance with all applicable regulations. This includes food safety regulations, environmental regulations, and labor laws.

- Monitor compliance with food safety regulations

- Monitor compliance with environmental regulations

- Monitor compliance with labor laws

- Work with regulatory agencies to ensure compliance

Interview Tips

Here are some tips to help you ace your interview for a Food Processing Plant Manager position:

1. Research the Company

Before you go to your interview, take some time to research the company. This will help you understand their business, their values, and their goals. This will also help you answer questions about the company and its culture in a thoughtful and informed way.

- Visit the company’s website

- Read about the company in the news

- Talk to people who work or have worked for the company

- Get a sense of the company’s size, scope, and reputation

2. Practice Your Answers

Take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Think about your experiences and accomplishments and how they relate to the job requirements

- Prepare specific examples of your work that demonstrate your skills and abilities

- Practice answering questions about your strengths, weaknesses, and career goals

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or business casual attire.

- Choose clothing that is clean, pressed, and fits well

- Avoid wearing revealing or distracting clothing

- Make sure your shoes are clean and polished

4. Be On Time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, call or email the interviewer to let them know.

- Plan your route ahead of time and leave yourself plenty of time to get to the interview location

- Allow for unexpected delays, such as traffic or parking issues

- If you are running late, call or email the interviewer to let them know

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and genuine in your answers

- Show the interviewer your personality and enthusiasm

- Don’t be afraid to ask questions

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Food Processing Plant Manager interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!