Are you gearing up for a career in Footwear Stitcher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Footwear Stitcher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

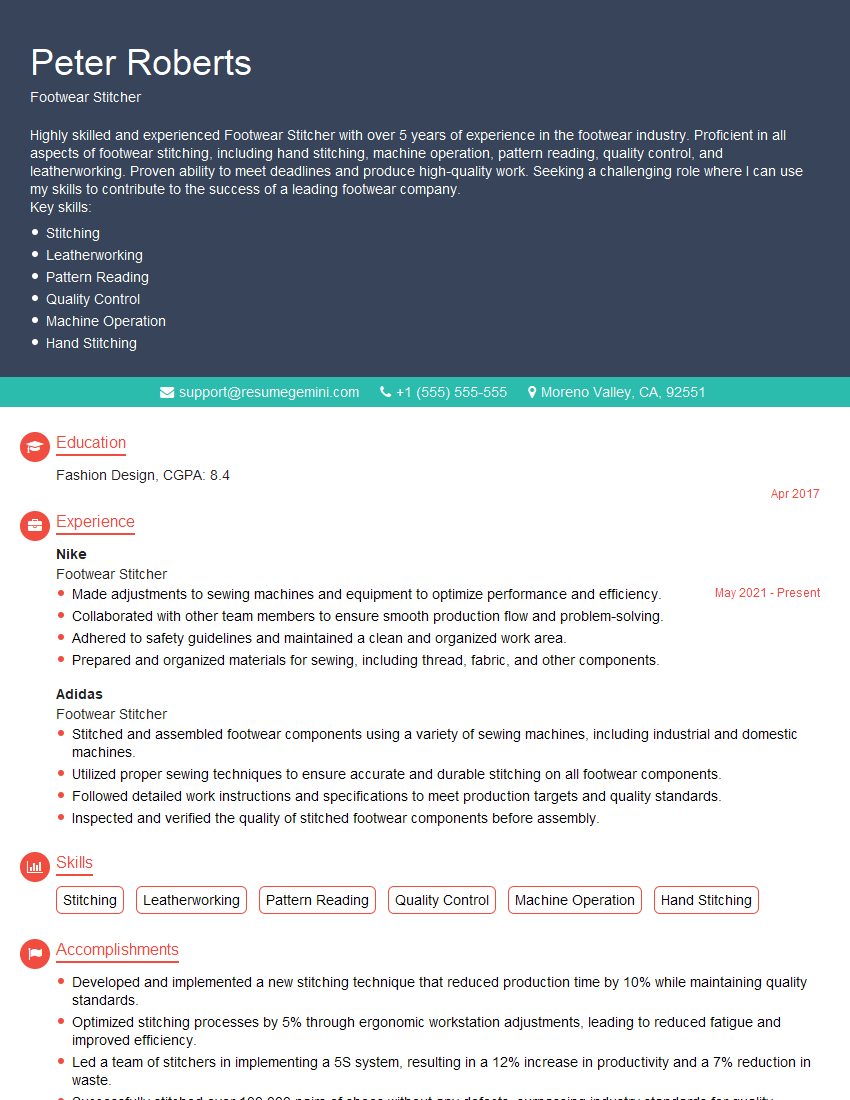

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Footwear Stitcher

1. Explain the process of stitching leather uppers to outsoles?

The process of stitching leather uppers to outsoles involves several steps:

- Preparing the materials: The leather uppers and outsoles are cut and shaped to the desired design.

- Applying adhesive: Adhesive is applied to the edges of the uppers and outsoles to create a strong bond.

- Stitching: The uppers and outsoles are stitched together using a specialized sewing machine. The stitch type and thread size are selected based on the material and desired strength.

- Trimming and finishing: The excess material around the edges is trimmed, and the stitching is reinforced with glue or sealant for durability.

2. What are the different types of footwear stitching machines?

- Lockstitch machines: These machines create a strong, durable stitch that is commonly used in footwear construction.

- Chain stitch machines: These machines produce a flexible, stretchy stitch that is often used for athletic shoes and other footwear that requires flexibility.

- Zigzag stitch machines: These machines create a decorative and durable stitch that is often used for embellishing footwear.

3. How do you ensure the accuracy and consistency of stitching?

To ensure accuracy and consistency, I follow these practices:

- Proper machine setup: The stitching machine is calibrated and adjusted to the correct stitch length, tension, and presser foot pressure.

- Precise material placement: The uppers and outsoles are carefully aligned and positioned before stitching to prevent misalignment.

- Consistent stitching technique: I maintain a steady hand and ensure that the stitching is even and uniform throughout the footwear.

- Regular quality checks: Throughout the stitching process, I inspect the work for accuracy, consistency, and any potential defects.

4. What are some common problems encountered in footwear stitching and how do you resolve them?

- Skipped stitches: This can be caused by improper thread tension or a dull needle. I adjust the tension or replace the needle to resolve it.

- Uneven stitching: This can be caused by inconsistent hand pressure or machine calibration. I adjust my technique or recalibrate the machine.

- Thread breakage: This can be caused by low-quality thread or a damaged needle. I replace the thread or needle to prevent further breakage.

5. How do you stay up-to-date with the latest advancements in footwear stitching techniques?

I stay updated by:

- Attending industry conferences and exhibitions: These events provide opportunities to learn about new technologies and techniques.

- Reading trade publications and online resources: I subscribe to magazines and websites dedicated to footwear production to stay informed about industry trends.

- Networking with other footwear professionals: Connecting with experienced stitchers and engineers allows me to exchange knowledge and learn from others.

6. What safety precautions do you take while working with footwear stitching machines?

- Wear appropriate protective gear: I wear safety glasses, gloves, and earplugs to protect myself from flying debris and noise.

- Maintain a clean work area: I keep my workstation tidy and free of clutter to prevent accidents.

- Follow proper machine operation procedures: I adhere to the manufacturer’s guidelines for safe machine operation and maintenance.

7. How do you prioritize your tasks and manage your time effectively?

I prioritize my tasks based on urgency and importance. I use a to-do list and set deadlines for each task to ensure timely completion.

- Urgent tasks: I address urgent tasks immediately to meet critical deadlines.

- Important but non-urgent tasks: I schedule these tasks for completion within a reasonable time frame to maintain productivity.

- Less important tasks: I complete these tasks when I have extra time available.

8. What is your approach to working in a team environment?

- Communication: I actively communicate with team members to share information and coordinate efforts.

- Collaboration: I assist team members when needed and contribute to the overall success of the team.

- Respect: I value and respect the opinions and contributions of others.

9. How do you handle errors or mistakes in your work?

When I encounter errors, I:

- Acknowledge the mistake: I take responsibility for my actions and acknowledge the error.

- Analyze the cause: I investigate why the error occurred to prevent similar mistakes in the future.

- Take corrective action: I take steps to correct the mistake and ensure it does not happen again.

10. Why are you interested in this footwear stitcher position?

I am eager to join your company because:

- Expertise in footwear stitching: I possess the technical skills and experience in footwear stitching, making me a valuable asset to your team.

- Dedication to quality: I am committed to producing high-quality footwear and exceeding industry standards.

- Drive for success: I am motivated and determined to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Footwear Stitcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Footwear Stitcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Footwear Stitchers play a crucial role in the production of footwear, ensuring the durability and aesthetics of the final product. Their key responsibilities encompass a wide range of tasks, including:

1. Precision Stitching

Footwear Stitchers skillfully operate sewing machines to stitch together various components of footwear, such as uppers, soles, and linings. They meticulously follow prescribed patterns and specifications to achieve precise and durable stitching that meets industry standards.

- Operate and maintain industrial sewing machines

- Follow detailed stitching patterns

- Ensure proper tension and alignment of stitches

2. Material Preparation

Prior to stitching, Footwear Stitchers prepare materials by selecting the appropriate threads, needles, and other supplies. They also inspect materials for defects and ensure that they meet the required specifications for the specific footwear design.

- Select and install correct needles and threads

- Inspect materials for imperfections

- Prepare materials for stitching (e.g., folding, trimming)

3. Quality Control

Throughout the stitching process, Footwear Stitchers diligently inspect their work to identify and rectify any defects or inconsistencies. They maintain high standards of quality, adhering to established guidelines and specifications to ensure the durability and appearance of the finished footwear.

- Inspect stitched components for accuracy and quality

- Identify and correct stitching errors

- Maintain consistent stitching standards

4. Production Efficiency

Footwear Stitchers contribute to the overall production efficiency by working within designated production schedules and timelines. They strive to meet or exceed production targets while maintaining a high level of quality in their work.

- Meet production targets and deadlines

- Maximize machine utilization

- Follow established production processes

Interview Tips

Preparing for an interview for a Footwear Stitcher position requires a combination of technical knowledge and a strong understanding of the company and industry. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and product line. Research the footwear industry, including current trends, materials, and manufacturing techniques. This knowledge will demonstrate your interest in the industry and the company.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating sewing machines and your attention to detail. Provide specific examples of your ability to produce high-quality stitching that meets industry standards. Describe any experience you have with different types of footwear and materials.

3. Prepare for Technical Questions

Anticipate questions related to stitching techniques, machine maintenance, and quality control procedures. Prepare to explain your understanding of these concepts and provide examples of how you have applied them in your previous work experience.

4. Practice Answering Common Interview Questions

Review common interview questions and practice answering them. This will help you gain confidence and structure your responses effectively. Consider questions about your strengths, weaknesses, and why you are interested in the position.

5. Demonstrate Enthusiasm and a Positive Attitude

Conveying your enthusiasm for the role and the industry can make a lasting impression on the interviewer. Show that you are eager to learn, grow, and contribute to the company’s success. Maintain a positive attitude throughout the interview, even if you encounter challenging questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Footwear Stitcher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!