Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Foreman/Pile Driving and Erection position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

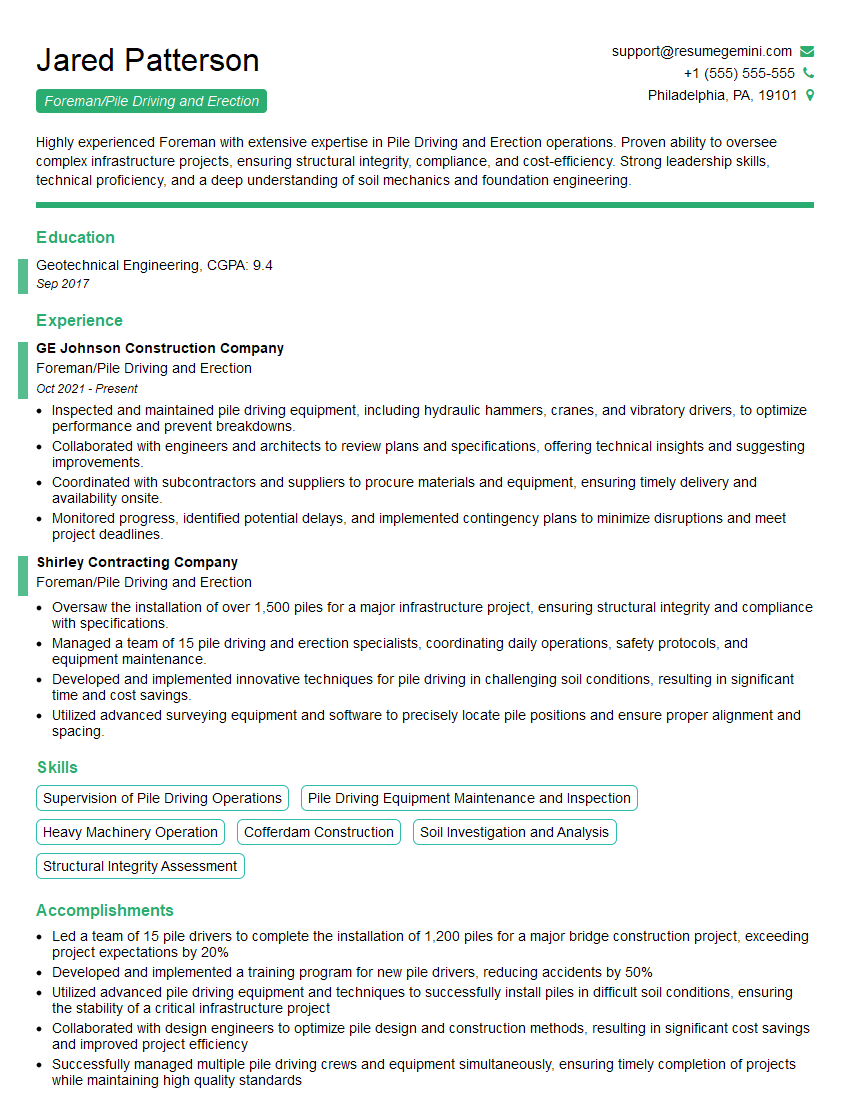

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foreman/Pile Driving and Erection

1. Explain the process of pile driving in detail and the methods associated with it.

- Driving piles manually: This method involves the use of hand tools to drive piles into the ground. It is typically used for small-scale projects and in areas where access to heavy machinery is limited.

- Using hydraulic hammers: This method employs hydraulically powered hammers to drive piles into the ground. It is a relatively quick and efficient method, and it is often used for large-scale projects.

- Using diesel hammers: This method utilizes diesel-powered hammers to drive piles into the ground. It is similar to the hydraulic hammer method, but it can be more noisy and less environmentally friendly.

- Vibratory driving: This method involves the use of a vibratory hammer to drive piles into the ground. It is a quieter and more environmentally friendly method than the impact driving methods, but it can be less effective in harder soils.

2. What are the different types of piles used in pile driving and their respective applications?

Timber piles:

- Made from wood, they are typically used in marine environments and for temporary structures.

- Advantages: Low cost, readily available, can be easily cut and shaped.

- Disadvantages: Susceptible to rot and damage by marine organisms, limited load-bearing capacity.

Concrete piles:

- Made from reinforced concrete, they are commonly used for permanent structures and in areas with high load-bearing requirements.

- Advantages: Durable, strong, can be customized to meet specific requirements.

- Disadvantages: Heavy, expensive, can be difficult to handle and install.

Steel piles:

- Made from steel, they are used in various applications, including bridges, buildings, and offshore structures.

- Advantages: High strength-to-weight ratio, corrosion-resistant, long lifespan.

- Disadvantages: Expensive, can be noisy during installation.

3. Elaborate on the safety measures that should be implemented during pile driving operations.

- Proper training and certification of operators: Ensure that all personnel involved in pile driving operations are adequately trained and certified to handle the equipment and follow safety protocols.

- Use of personal protective equipment (PPE): Require all workers to wear appropriate PPE, such as hard hats, safety glasses, gloves, and earplugs, to protect themselves from hazards.

- Establish a safe work zone: Clearly mark and barricade the work area to prevent unauthorized entry and protect workers and equipment from potential hazards.

- Regular inspection and maintenance of equipment: Conduct regular inspections and maintenance on all pile driving equipment to ensure it is in good working condition and meets safety standards.

4. What factors influence the choice of pile driving method?

- Soil conditions: The type of soil at the construction site will determine the most suitable pile driving method. Different methods are better suited for different soil types.

- Load requirements: The weight and load that the piles will be subjected to will influence the choice of method. Some methods can handle heavier loads than others.

- Environmental considerations: Noise, vibration, and environmental impact can be factors in selecting a pile driving method, especially in sensitive areas.

- Cost and availability: The cost and availability of equipment and labor can also influence the choice of method.

5. Discuss the importance of pile testing and the different methods used for testing piles.

- Pile load testing: This method involves applying a known load to a pile and measuring its response, such as settlement or deflection, to determine its load-bearing capacity.

- Ultrasonic testing: This non-destructive method uses ultrasonic waves to detect defects or anomalies within a pile.

- Cross-hole sonic logging: This method involves inserting a sonic logging tool into a pile and measuring the velocity of sound waves to evaluate the pile’s integrity.

- Dynamic load testing: This method uses a dynamic load to excite the pile and measure its vibration response to assess its stiffness and damping characteristics.

6. Explain the process of pile capping and its purpose.

- Pile capping involves connecting the tops of individual piles together using a concrete cap or grillage.

- Purpose:

- Distribute the load from the superstructure evenly across the piles.

- Provide a stable and level surface for the superstructure.

- Protect the pile tops from weathering and damage.

7. What are the challenges faced during pile driving operations and how can they be overcome?

Challenges:

- Ground conditions: Hard or rocky ground can make pile driving difficult and may require specialized equipment or techniques.

- Obstructions: Underground obstacles, such as boulders or buried utilities, can hinder pile driving and may need to be removed or worked around.

- Environmental impact: Noise, vibration, and dust generated during pile driving can be concerns, especially in urban areas.

Overcoming challenges:

- Using appropriate equipment: Selecting the right pile driving equipment and techniques for the specific soil conditions and obstacles can help mitigate challenges.

- Careful planning: Thorough site investigations and planning can help identify potential obstacles and develop strategies to address them.

- Mitigation measures: Implementing measures such as noise barriers, vibration dampening systems, and dust control can help minimize environmental impact.

8. Describe the role of the foreman in pile driving and erection operations.

- Supervise and coordinate all aspects of pile driving and erection operations, including crew, equipment, and materials.

- Ensure that all operations are carried out safely and efficiently.

- Monitor progress, identify and address any issues or delays, and make necessary adjustments.

- Communicate with engineers, contractors, and clients to provide updates and resolve any queries.

9. What are the qualities and skills required to be an effective foreman in pile driving and erection?

- Technical expertise: Strong understanding of pile driving and erection techniques, equipment, and industry standards.

- Leadership and management skills: Ability to lead and motivate a team, manage resources, and ensure smooth operations.

- Problem-solving and decision-making skills: Capacity to identify and resolve issues promptly, adapting to changing conditions.

- Communication and interpersonal skills: Excellent communication skills to interact effectively with team members, contractors, and clients.

10. How do you stay up-to-date with the latest advancements and best practices in pile driving and erection?

- Attend industry conferences and workshops: Participate in events to learn about new technologies, techniques, and industry trends.

- Read technical journals and publications: Stay informed about the latest research and developments in the field.

- Network with peers and industry experts: Engage with other professionals to exchange knowledge and experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foreman/Pile Driving and Erection.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foreman/Pile Driving and Erection‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foremen/Pile Driving and Erection hold crucial managerial responsibilities for pile driving and erection operations, ensuring the safety and efficiency of projects. They oversee every aspect, from coordinating crews and planning operations to managing materials and equipment.

1. Project Management

Foremen plan and organize pile driving and erection projects, coordinating with engineers, architects, and other stakeholders. They develop project schedules, allocate resources, and monitor progress to ensure timely and cost-effective completion.

- Develop and implement project plans and schedules

- Coordinate with contractors, subcontractors, and suppliers

- Monitor project progress and make necessary adjustments

2. Crew Supervision

Foremen lead and supervise pile driving and erection crews, ensuring safety and productivity. They assign tasks, provide training, and monitor performance to maintain efficiency and quality standards.

- Hire, train, and supervise crew members

- Assign tasks and provide guidance

- Monitor performance and provide feedback

3. Equipment Management

Foremen manage and maintain equipment used in pile driving and erection, including pile drivers, cranes, and other machinery. They ensure that equipment is safe and operational, adhering to safety regulations and manufacturer recommendations.

- Inspect and maintain equipment regularly

- Coordinate repairs and maintenance as needed

- Ensure that equipment meets safety standards

4. Safety Management

Foremen prioritize safety in all aspects of pile driving and erection operations. They establish and implement safety protocols, conduct safety inspections, and enforce safety regulations to minimize risks and prevent accidents.

- Develop and implement safety plans and protocols

- Conduct safety inspections and identify potential hazards

- Train crew members on safety procedures

Interview Preparation Tips

To ace your interview for Foreman/Pile Driving and Erection, it’s crucial to prepare thoroughly and showcase your relevant skills and experience. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to learn about the company’s history, values, and current projects. Research the specific responsibilities of the Foreman/Pile Driving and Erection role to demonstrate your understanding of the position.

2. Prepare Your Resume and Portfolio

Tailor your resume and portfolio to highlight your relevant skills and experience. Emphasize your expertise in pile driving and erection, crew supervision, equipment management, and safety protocols. Include specific examples of successful projects you’ve led.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Practice answering questions about your leadership style, safety record, and experience managing large-scale projects. Use the STAR method (Situation, Task, Action, Result) to provide specific and detailed examples.

4. Be Familiar with Industry Standards and Best Practices

Demonstrate your knowledge of industry standards and best practices for pile driving and erection. Highlight your understanding of safety regulations, quality control measures, and environmental considerations.

5. Ask Informed Questions

At the end of the interview, ask thoughtful questions to show your interest and engagement. Inquire about the company’s growth plans, the team culture, and the specific challenges involved in the role.

6. Dress Professionally and Be Punctual

Make a positive first impression by dressing professionally and arriving on time for your interview. Your appearance and demeanor convey respect and attention to detail.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Foreman/Pile Driving and Erection interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.