Are you gearing up for a career in Forge Press Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Forge Press Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

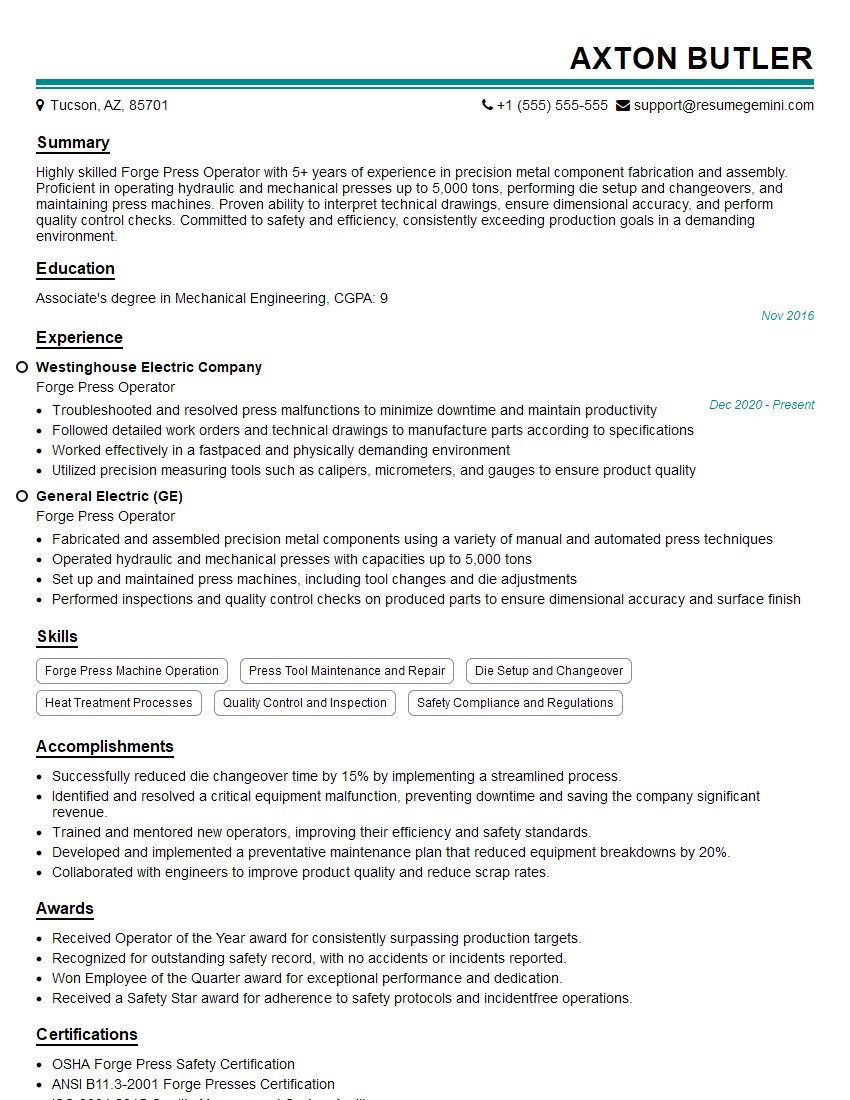

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forge Press Operator

1. Describe the process of forging a part on a forge press?

In the forge press forging process, a workpiece is heated to a high temperature and then pressed between two dies to shape it. The dies can be made of various materials, such as steel or cast iron, and are designed to create the desired shape in the workpiece. The workpiece is placed between the dies, and the press is activated, applying immense pressure to the workpiece, causing it to conform to the shape of the dies. The workpiece is then cooled and removed from the press.

2. What are the different types of forge presses?

Mechanical Forge Presses

- Use a flywheel to store energy and deliver it to the ram in a single stroke.

- Can be used for a wide range of forging operations.

- Typically have a lower production rate than hydraulic presses.

Hydraulic Forge Presses

- Use hydraulic pressure to power the ram.

- Capable of delivering a consistent and smooth force throughout the stroke.

- Offer a higher production rate than mechanical presses.

- Can be used for forging complex shapes.

Friction Screw Forge Presses

- Use a rotating screw to generate friction, which heats the workpiece and makes it more malleable.

- Suitable for forging small, intricate parts.

- Can produce high-quality forgings with minimal material waste.

3. What are the key factors to consider when selecting a forge press?

- Type of forging operation

- Size and complexity of the workpiece

- Production rate required

- Available budget

- Space constraints

4. What are the common safety hazards associated with forge press operation?

- Pinch points between the dies

- Flying debris

- High temperatures

- Noise

- Electrical hazards

5. What are the steps involved in maintaining a forge press?

Regular maintenance is crucial to ensure the safe and efficient operation of a forge press.

- Inspecting the press for any damage or wear.

- Lubricating all moving parts.

- Checking the hydraulic system for leaks or contamination.

- Calibrating the press to ensure accurate operation.

- Following manufacturer’s recommended maintenance schedule.

6. What are some troubleshooting tips for forge press operation?

- If the press is not applying enough pressure, check the hydraulic system for leaks or contamination.

- If the press is making excessive noise, check for loose bolts or worn gears.

- If the workpiece is not being forged to the desired shape, check the dies for wear or damage.

- If the press is overheating, check the cooling system for any blockages.

- If the press is experiencing any other problems, consult the manufacturer’s manual or contact a qualified technician.

7. What are the different types of dies used in forge press operations?

- Open dies: Allow for unrestricted metal flow, used for simple shapes like bars or sheets.

- Closed dies: Enclose the workpiece, used for more complex shapes with closer tolerances.

- Impression dies: Create specific impressions or features on the workpiece.

- Flashless dies: Produce forgings with minimal or no flash, reducing material waste.

- Combination dies: Combine multiple operations into a single die, increasing efficiency.

8. How do you ensure the quality of forged parts?

Quality assurance is crucial in forge press operation to ensure the parts meet specifications and perform as intended.

- Inspecting raw materials before forging.

- Monitoring the forging process to ensure proper temperature and pressure.

- Conducting dimensional and hardness testing on finished parts.

- Implementing statistical process control techniques to identify and minimize variations.

- Following industry standards and best practices.

9. What are some recent advancements in forge press technology?

Technological advancements are continuously improving the capabilities and efficiency of forge presses.

- Automated loading and unloading systems.

- Servo-controlled presses for precise and repeatable operation.

- Finite element analysis (FEA) for optimizing die design and forging processes.

- Advanced sensors and monitoring systems for real-time data collection and analysis.

- Integration with Industry 4.0 technologies for enhanced connectivity and data management.

10. How do you stay up-to-date with the latest industry trends and best practices in forge press operation?

Keeping up with industry advancements is essential for continuous improvement and maintaining competitiveness.

- Attending industry conferences and exhibitions.

- Reading trade publications and technical journals.

- Participating in online forums and discussions.

- Consulting with experts and vendors in the field.

- Seeking professional development opportunities, such as workshops and training programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forge Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forge Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Forge Press Operators play a crucial role in the metalworking industry by operating and maintaining forging presses. Their responsibilities encompass a wide range of tasks, ensuring the smooth production of forged components.

1. Machine Operation

Forge Press Operators are responsible for operating various types of forging presses, including mechanical, hydraulic, and power presses.

- Set up and adjust press parameters, such as pressure, stroke length, and speed.

- Load and unload forging dies into the press and align them precisely.

- Operate the press safely and efficiently to produce forged parts to the required specifications.

2. Die Maintenance

To ensure the quality and consistency of forged parts, Forge Press Operators are also responsible for maintaining and repairing forging dies.

- Inspect dies regularly for wear and damage, and perform routine maintenance tasks.

- Dress and sharpen dies using specialized tools and equipment.

- Troubleshoot and resolve any issues related to die performance.

3. Process Monitoring

Forge Press Operators play a critical role in monitoring the forging process to prevent defects and ensure product quality.

- Monitor temperature, pressure, and other process parameters during forging operations.

- Inspect forged parts for dimensional accuracy, surface finish, and other quality attributes.

- Identify and rectify any deviations from the specified forging parameters.

4. Safety and Compliance

As Forge Press Operators work with heavy machinery and hot materials, they have a responsibility to adhere to safety regulations and maintain a safe work environment.

- Follow all established safety protocols and wear appropriate protective gear.

- Maintain the work area clean and organized, free from hazards.

- Report any safety concerns or incidents promptly to their supervisor.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of making a positive impression and landing the job. Here are some tips to help you prepare for a Forge Press Operator interview:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific job requirements. This will enable you to tailor your answers to the interviewer’s questions and demonstrate your interest in the role.

- Visit the company’s website to learn about their products, services, and company culture.

- Read the job description carefully and identify the key skills and qualifications they’re looking for.

- Prepare specific examples from your past experience that highlight your relevant skills and abilities.

2. Practice Common Interview Questions

There are a number of common interview questions that you’re likely to encounter in a Forge Press Operator interview. Practicing your answers to these questions will help you feel more confident and prepared during the interview.

- Tell me about your experience operating forging presses.

- Describe a time when you had to troubleshoot a problem with a forging die.

- How do you ensure that forged parts meet the required quality standards?

3. Showcase Your Safety Knowledge

As safety is a critical aspect of Forge Press Operator roles, be prepared to talk about your safety knowledge and practices in detail.

- Explain your understanding of the relevant safety regulations and protocols.

- Describe your experience in maintaining a safe work environment.

4. Emphasize Your Physical Ability

Forge Press Operators often need to lift heavy objects and work in physically demanding conditions. Be sure to emphasize your physical strength and stamina in the interview.

- Mention any previous experience you have in physically demanding roles.

- Highlight your ability to work long hours and handle heavy workloads.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Forge Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!