Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Forge Shop Machine Repairer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Forge Shop Machine Repairer so you can tailor your answers to impress potential employers.

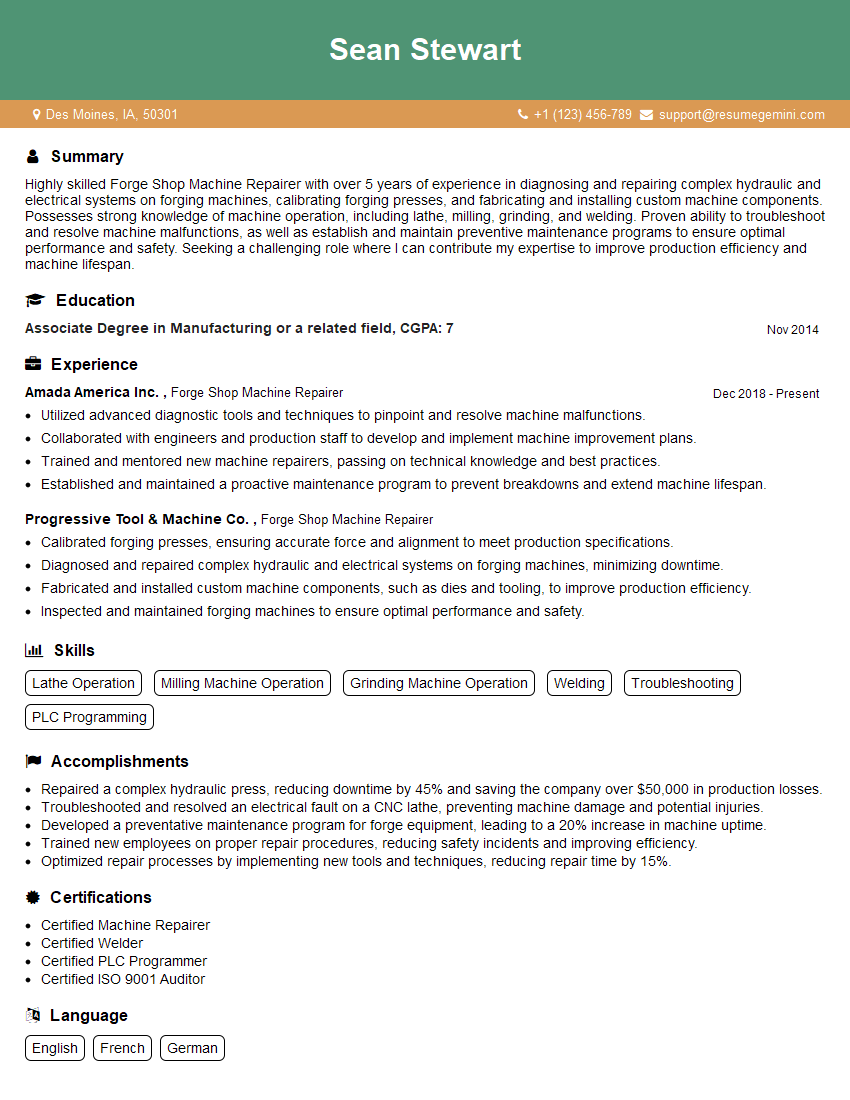

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forge Shop Machine Repairer

1. Explain the steps involved in repairing a forge shop machine?

- Identify the problem with the machine.

- Gather the necessary tools and materials.

- Disassemble the machine to access the damaged parts.

- Repair or replace the damaged parts.

- Reassemble the machine and test it to ensure it is working properly.

2. What safety precautions should be taken when working on forge shop machines?

- Always wear appropriate safety gear, including eye protection, gloves, and a hard hat.

- Never operate a machine without proper training.

- Keep the work area clean and free of tripping hazards.

- Be aware of moving parts and hot surfaces.

- Never reach into a machine while it is running.

3. How do you troubleshoot a forge shop machine that is not working properly?

- Check the power supply to the machine.

- Inspect the machine for any visible damage.

- Listen for any unusual sounds or vibrations.

- Use a multimeter to test the electrical components of the machine.

- Consult the machine’s manual for troubleshooting tips.

4. What are the different types of forge shop machines?

- Power hammers

- Presses

- Shears

- Grinders

- Lathes

- Milling machines

- Welding machines

5. What are the most common problems that you encounter in forge shop machines?

- Electrical problems

- Mechanical problems

- Hydraulic problems

- Pneumatic problems

- Software problems

6. What are the steps involved in preventive maintenance for forge shop machines?

- Regularly inspect the machines for any signs of wear or damage.

- Clean and lubricate the machines according to the manufacturer’s instructions.

- Check the electrical connections and wiring.

- Test the safety features of the machines.

- Keep a maintenance log to track all maintenance activities.

7. What are the benefits of using forge shop machines?

- Increased productivity

- Improved accuracy

- Reduced labor costs

- Improved safety

- Reduced downtime

8. What are the challenges of working as a forge shop machine repairer?

- Working in a noisy and dusty environment

- Working with heavy machinery

- Dealing with hazardous materials

- Working under pressure to meet deadlines

- Need to be physically strong and have good hand-eye coordination

9. What are the qualities of a successful forge shop machine repairer?

- Strong mechanical skills

- Good troubleshooting skills

- Ability to work independently and as part of a team

- Physical strength and stamina

- Good communication skills

10. What is your favorite thing about working as a forge shop machine repairer?

I enjoy the challenge of troubleshooting and repairing machines. I also like the satisfaction of knowing that I am helping to keep the machines running smoothly and safely.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forge Shop Machine Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forge Shop Machine Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Forge Shop Machine Repairers are maintenance professionals responsible for the maintenance, repair, and installation of production machinery in a forge shop.

1. Troubleshooting and Repair

Diagnose mechanical and electrical problems with forge shop equipment, including presses, hammers, and furnaces.

- Analyze equipment breakdowns.

- Identify faulty parts and components.

2. Machine Maintenance and Calibration

Perform regular maintenance and calibration on equipment to ensure optimal performance and prevent breakdowns.

- Lubricate, adjust, and replace parts as needed.

- Calibrate machinery according to manufacturer specifications.

3. Equipment Installation and Modifications

Install, modify, and relocate equipment based on production needs and safety regulations.

- Review and interpret blueprints and engineering drawings.

- Ensure proper alignment and level installation.

4. Safety and Compliance

Maintain a safe and compliant work environment by adhering to safety regulations and procedures.

- Identify and mitigate potential hazards.

- Participate in safety inspections and training.

Interview Tips

Preparing for an interview for a Forge Shop Machine Repairer position requires thorough knowledge of the role’s responsibilities and the industry. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Gain a deep understanding of the forge shop industry, its practices, and the specific company you are interviewing for.

- Visit the company website and read their mission statement, values, and recent news.

- Research the industry through trade publications and online resources.

2. Highlight Relevant Skills and Experience

Emphasize your mechanical and electrical troubleshooting abilities, machine maintenance expertise, and safety awareness.

- Provide specific examples of how you have successfully diagnosed and repaired machinery.

- Discuss your experience in maintaining and calibrating equipment to ensure peak performance.

3. Showcase Your Safety Knowledge

Demonstrate your understanding of safety protocols in a forge shop environment.

- Explain your experience in identifying and mitigating potential hazards.

- Discuss your knowledge of OSHA regulations and other applicable safety standards.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to forge shop equipment, such as:

- How do you troubleshoot electrical problems in a hydraulic press?

- Explain the process of aligning a forging hammer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Forge Shop Machine Repairer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.