Are you gearing up for a career in Forge Utility Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Forge Utility Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

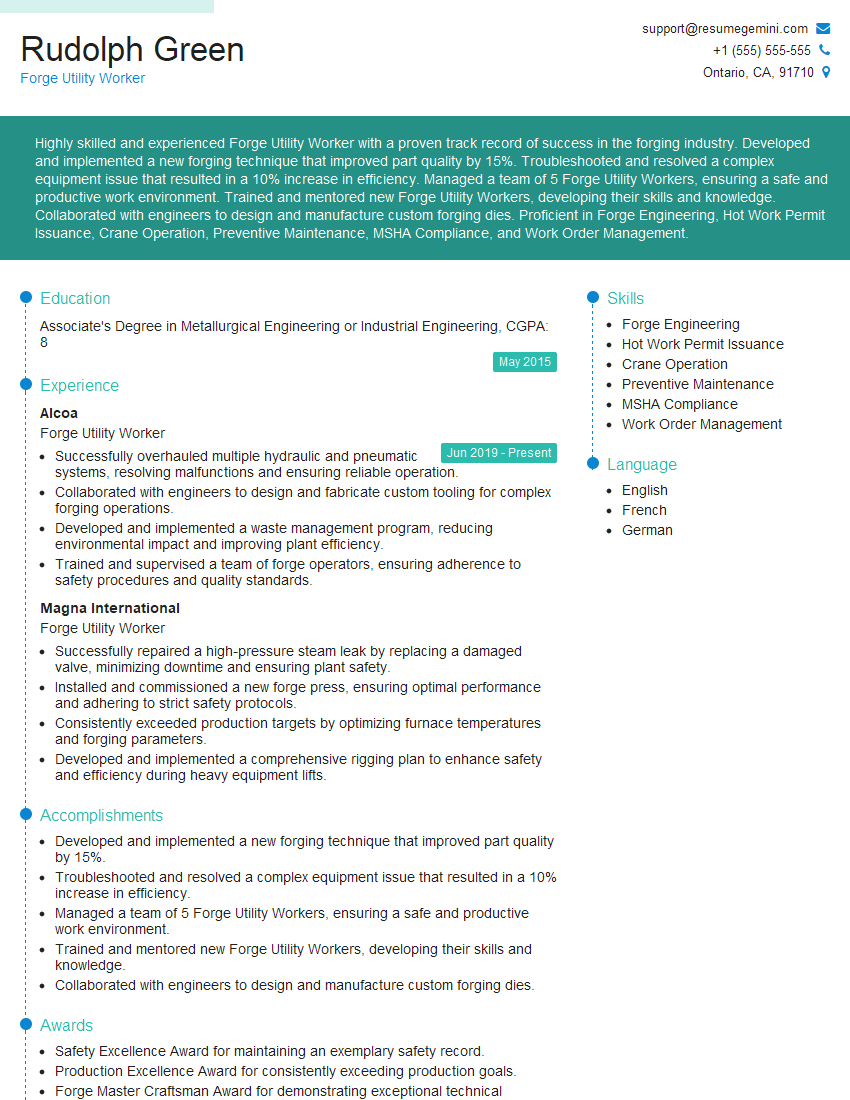

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forge Utility Worker

1. What are the different types of forging processes?

There are a variety of forging processes, each with its own advantages and disadvantages. Some of the most common types include:

- Open-die forging

- Closed-die forging

- Roll forging

- Press forging

- Hammer forging

2. What are the different types of forging hammers?

There are two main types of forging hammers: steam hammers and air hammers. Steam hammers are powered by steam, while air hammers are powered by compressed air. Each type of hammer has its own advantages and disadvantages.

Steam hammers

- Advantages: powerful, versatile, can be used for a wide range of forging operations

- Disadvantages: expensive to operate, require a skilled operator

Air hammers

- Advantages: less expensive to operate than steam hammers, easier to control, can be used for a variety of forging operations

- Disadvantages: not as powerful as steam hammers

3. What are the different types of forging dies?

There are a variety of forging dies, each designed for a specific purpose. Some of the most common types include:

- Flat dies

- Impression dies

- Forming dies

- Trimming dies

4. What are the different types of forging furnaces?

There are a variety of forging furnaces, each with its own advantages and disadvantages. Some of the most common types include:

- Gas furnaces

- Oil furnaces

- Electric furnaces

- Induction furnaces

5. What are the different types of forging lubricants?

There are a variety of forging lubricants, each designed for a specific purpose. Some of the most common types include:

- Oil-based lubricants

- Water-based lubricants

- Graphite-based lubricants

- Molybdenum disulfide-based lubricants

6. What are the different types of forging defects?

There are a variety of forging defects, each with its own cause. Some of the most common types include:

- Cracks

- Seams

- Tears

- Folds

- Cold shuts

7. What are the different types of forging safety hazards?

There are a variety of forging safety hazards, including:

- Fire

- Heat

- Noise

- Chemical exposure

- Physical hazards (e.g., falls, struck-by hazards)

8. What are the different types of forging personal protective equipment (PPE)?

There are a variety of forging PPE, including:

- Safety glasses

- Gloves

- Ear plugs

- Hard hat

- Safety shoes

9. What is the difference between annealing and normalizing?

Annealing and normalizing are two different heat treating processes that are used to improve the properties of forged parts. Annealing involves heating the part to a high temperature and then slowly cooling it. This process makes the part softer and more ductile. Normalizing involves heating the part to a high temperature and then cooling it in air. This process makes the part harder and stronger.

10. What is the difference between tempering and hardening?

Tempering and hardening are two different heat treating processes that are used to improve the properties of forged parts. Tempering involves heating the part to a temperature below the hardening temperature and then cooling it. This process makes the part harder and more brittle. Hardening involves heating the part to a high temperature and then cooling it rapidly. This process makes the part harder and more wear-resistant.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forge Utility Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forge Utility Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Forge Utility Workers are responsible for operating and maintaining a variety of equipment used in forging. This includes hammers, presses, furnaces, and other machines. They also perform setup and maintenance tasks, and assist in the production of forged products.

1. Equipment Operation

Forge Utility Workers operate a variety of equipment used in forging, including hammers, presses, furnaces, and other machines. They are responsible for setting up and adjusting the equipment, and for operating it safely and efficiently.

- Set up and adjust forging equipment, including hammers, presses, furnaces, and other machines

- Operate equipment safely and efficiently

2. Setup and Maintenance

Forge Utility Workers perform setup and maintenance tasks on forging equipment. This includes cleaning and lubricating the equipment, and replacing worn parts. They also perform minor repairs on the equipment.

- Clean and lubricate forging equipment

- Replace worn parts

- Perform minor repairs on forging equipment

3. Production Assistance

Forge Utility Workers assist in the production of forged products. This includes loading and unloading materials, and operating the equipment. They also assist in the inspection of forged products.

- Load and unload materials

- Operate equipment

- Assist in the inspection of forged products

4. Safety and Environmental Compliance

Forge Utility Workers are responsible for following safety and environmental regulations. This includes wearing proper personal protective equipment, and following safe work practices. They also follow environmental regulations, such as those related to waste disposal.

- Wear proper personal protective equipment

- Follow safe work practices

- Follow environmental regulations

Interview Tips

Preparing for an interview can be a daunting task, but it is important to remember that the interviewer is looking for someone who is qualified for the job and who will be a good fit for the company. Here are a few tips to help you ace your interview for a Forge Utility Worker position:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and what they are looking for in a Forge Utility Worker.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Write down your answers to common interview questions

- Practice saying your answers out loud

- Time yourself to make sure your answers are concise

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience working in a forge. Be prepared to talk about your skills and experience in operating and maintaining forging equipment, and in assisting in the production of forged products.

- Highlight your skills and experience in operating and maintaining forging equipment

- Discuss your experience in assisting in the production of forged products

- Quantify your accomplishments whenever possible

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Wear clean, pressed clothes

- Arrive on time for your interview

- Be polite and respectful to the interviewer

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Forge Utility Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!