Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Forklift Wheel Loader position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

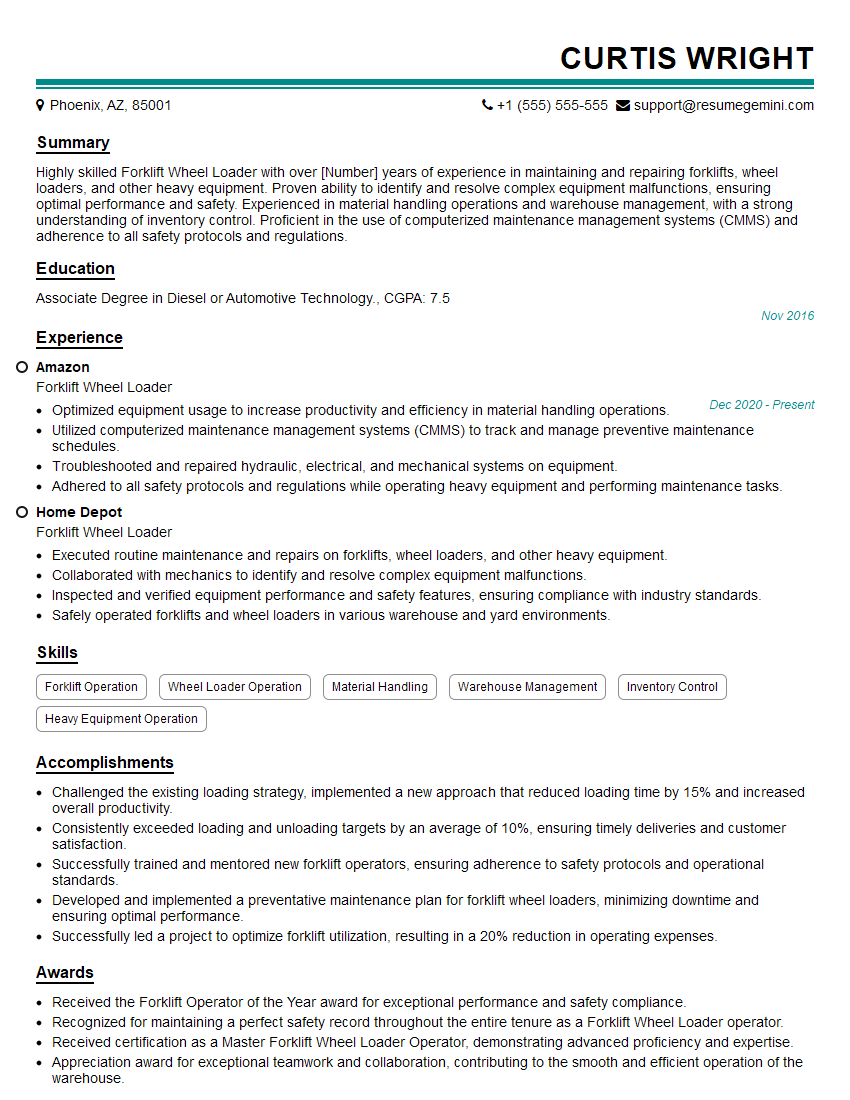

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forklift Wheel Loader

1. What is the purpose of a load weight sensor on a forklift wheel loader?

To ensure the safe operation of a forklift wheel loader, it is equipped with a load weight sensor that serves several important purposes:

- Load Monitoring: The sensor continuously measures the weight of the load being lifted by the forklift.

- Overload Prevention: It alerts the operator and prevents the forklift from lifting loads exceeding its rated capacity, thus safeguarding against potential accidents.

- Stability Enhancement: The load weight sensor provides real-time data to the forklift’s stability system. This information allows the system to adjust the forklift’s center of gravity and optimize its stability, especially when handling heavy or unbalanced loads.

2. Describe the key components of a hydrostatic transmission system used in a forklift wheel loader and explain their functions.

Components of a Hydrostatic Transmission System:

- Transmission Pump: Converts mechanical energy from the engine into hydraulic energy.

- Hydraulic Motor: Converts hydraulic energy back into mechanical energy, powering the wheels.

- Control Valves: Regulate the flow of hydraulic fluid, controlling the speed and direction of the forklift.

Functions of Hydrostatic Transmission System:

- Smooth Operation: Hydrostatic transmission provides smooth and precise control over the forklift’s speed and direction.

- Efficiency and Power: This system is highly efficient and can deliver high levels of torque, making it suitable for challenging applications.

- Compact Design: Hydrostatic transmission systems are relatively compact, allowing for more space optimization within the forklift’s design.

3. Explain the importance of regular maintenance for forklift wheel loaders and describe some key maintenance tasks.

Regular maintenance is crucial for ensuring the safety, performance, and longevity of forklift wheel loaders. Key maintenance tasks include:

- Fluid Checks and Changes: Inspecting and changing fluids such as engine oil, hydraulic fluid, and coolant regularly helps prevent wear and tear.

- Tire Inspection and Maintenance: Tires play a vital role in stability and traction. Regularly checking tire pressure, tread depth, and wear patterns ensures optimal performance.

- Battery Maintenance: For electric forklifts, proper battery maintenance, including charging, watering, and cleaning terminals, is essential for longevity.

- Safety Inspections: Thorough safety inspections cover various components, including brakes, lights, forks, and load weight sensors, to ensure compliance and prevent accidents.

4. How do you assess and maintain the mast and forks of a forklift wheel loader?

Mast and forks are critical components of a forklift wheel loader. To assess and maintain them:

- Visual Inspection: Regularly inspect the mast and forks for any signs of damage, cracks, or wear.

- Load Weight Verification: Ensure the load weight sensor is calibrated correctly and that the forks are not overloaded.

- Lubrication: Lubricate the mast components according to the manufacturer’s recommendations to reduce friction and prevent premature wear.

- Fork Replacement: If the forks become damaged or worn beyond repair, they should be replaced promptly to prevent accidents.

5. Describe the role of the hydraulic system in a forklift wheel loader and explain how to troubleshoot common hydraulic issues.

The hydraulic system is essential for various functions of a forklift wheel loader, including lifting, tilting, and steering. To troubleshoot common hydraulic issues:

- Check Hydraulic Fluid Level: Ensure the hydraulic fluid reservoir is at the proper level and that the fluid is clean.

- Inspect Hoses and Lines: Look for any leaks, cracks, or wear in hoses and lines that could lead to fluid loss or pressure drops.

- Test Hydraulic Pressure: Use a pressure gauge to measure the hydraulic pressure at key points in the system and compare it to the manufacturer’s specifications.

- Examine Hydraulic Components: Inspect pumps, valves, and cylinders for any signs of damage or wear that could affect hydraulic performance.

6. Explain the importance of operator training and certification for forklift wheel loader operators.

Operator training and certification are paramount for several reasons:

- Safety: Trained operators understand the safe operation of forklifts, reducing the risk of accidents and injuries.

- Efficiency: Proper training improves operational efficiency, allowing operators to handle materials quickly and safely.

- Compliance: Many jurisdictions require operators to be certified to operate forklifts, ensuring compliance with regulations.

- Reduced Costs: Training and certification can reduce the likelihood of accidents and damage to equipment, leading to lower insurance costs and maintenance expenses.

7. How do you ensure the stability of a forklift wheel loader when lifting heavy loads?

To ensure stability when lifting heavy loads:

- Load Distribution: Position the load evenly on the forks and avoid overloading.

- Mast Tilt: Keep the mast tilted slightly forward to prevent the load from shifting backward.

- Speed Control: Operate the forklift slowly and smoothly, especially when turning or lifting heavy loads.

- Counterweight: Ensure the forklift has a sufficient counterweight to balance the load being lifted.

8. Describe the safety precautions you take when working with forklift wheel loaders in confined spaces.

Safety precautions in confined spaces include:

- Ventilation: Ensure proper ventilation to prevent exhaust gas accumulation.

- Overhead Obstacles: Be aware of overhead obstacles and clearances to avoid collisions.

- Lighting: Provide adequate lighting to enhance visibility and reduce the risk of accidents.

- Clearance: Maintain a safe distance from walls, equipment, and other objects to prevent damage or injury.

- Communication: Establish clear communication protocols with other workers in the confined space.

9. Explain the principles of load handling and stacking techniques for maximizing storage capacity.

Load handling and stacking techniques for maximizing storage capacity include:

- Stacking Patterns: Utilize vertical stacking patterns to optimize space utilization.

- Load Distribution: Distribute the weight of the load evenly across the forks to prevent overloading.

- Interlocking: Interlock the loads to create stable stacks, reducing the risk of collapse.

- Load Height: Determine the maximum safe stacking height based on the forklift’s capacity and the stability of the load.

- Aisle Width: Consider the forklift’s turning radius and aisle width to ensure efficient maneuvering.

10. How do you assess the condition of a used forklift wheel loader before purchasing it?

To assess the condition of a used forklift wheel loader before purchasing:

- Visual Inspection: Thoroughly inspect the forklift for any visible damage, cracks, or signs of wear.

- Operational Checks: Test the forklift’s lifting capacity, steering, and braking systems to ensure proper functionality.

- Maintenance Records: Request maintenance records to review the history of repairs and servicing.

- Load Weight Test: Perform a load weight test to verify the forklift’s capacity and stability.

- Professional Inspection: Consider hiring a qualified mechanic to conduct a comprehensive inspection before making a purchase decision.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forklift Wheel Loader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forklift Wheel Loader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Operate and Maintain Equipment

Operate forklift wheel loaders and other heavy equipment in a safe and efficient manner. Perform preventive maintenance, including daily inspections, lubrication, and minor repairs.

2. Material Handling

Load, transport, and unload materials such as pallets, crates, and machinery. Use attachments and accessories to handle specialized materials safely and effectively.

3. Warehouse Operations

Manage warehouse operations, including inventory control, space allocation, and equipment utilization. Ensure efficient and organized flow of materials.

4. Safety Compliance

Adhere to all safety regulations and operating procedures. Conduct regular safety inspections and ensure proper use of personal protective equipment (PPE).

5. Communication and Teamwork

Maintain effective communication with colleagues, supervisors, and customers. Work effectively in a team environment and contribute to a positive work atmosphere.

Interview Tips

To prepare for an interview for a Forklift Wheel Loader position, follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s values, industry, and specific requirements for the role. This will demonstrate your interest and understanding of the organization.

2. Highlight Relevant Skills and Experience

Showcase your proficiency in operating forklift wheel loaders and other heavy equipment. Emphasize your ability to handle materials efficiently, manage inventory, and maintain equipment.

3. Demonstrate Safety Awareness

Stress your commitment to safety and adherence to regulations. Mention your experience in conducting safety inspections and ensuring proper PPE usage.

4. Practice Common Interview Questions

Prepare answers to typical interview questions such as “Tell me about a time you handled a challenging material handling situation” or “How do you prioritize tasks in a busy warehouse environment?”

5. Be Enthusiastic and Professional

Convey your enthusiasm for the role and the industry. Dress professionally and maintain a positive attitude throughout the interview process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Forklift Wheel Loader role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.