Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Form Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

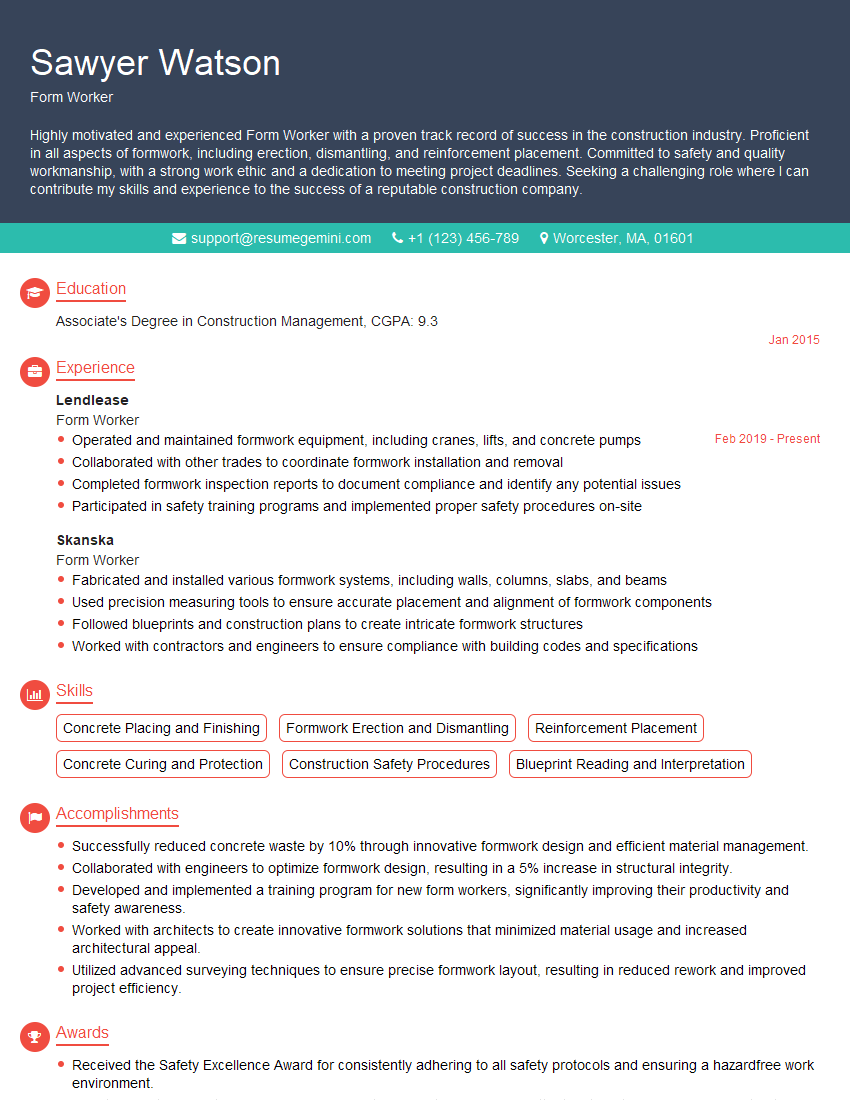

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Form Worker

1. Describe the process of preparing and installing formwork for a concrete foundation?

- Lay out the foundation area and excavate the soil to the desired depth.

- Install formwork panels around the perimeter of the foundation, securing them with stakes or clamps.

- Place reinforcing bars within the formwork, as specified in the engineering plans.

- Pour concrete into the formwork, ensuring it is evenly distributed and properly consolidated.

- Allow the concrete to cure for the specified period before removing the formwork.

2. How do you ensure the accuracy and stability of formwork structures?

Leveling and Alignment

- Use spirit levels and laser levels to ensure that the formwork is level and aligned.

- Check diagonals to ensure that the formwork is square or rectangular.

Bracing and Support

- Install bracing and supports to prevent bowing or collapse of the formwork.

- Use ties, struts, and walers to provide additional strength and stability.

Material Quality

- Select formwork materials that are durable, strong, and resistant to moisture.

- Inspect formwork panels for any damage or defects before installation.

3. What are the different types of formwork materials and their advantages/disadvantages?

- Plywood: Durable, versatile, and relatively inexpensive. Prone to warping and moisture damage.

- Metal: Strong, durable, and reusable. Can be expensive and heavy.

- Fiberglass: Lightweight, corrosion-resistant, and easy to handle. Can be more expensive than other materials.

- Plastic: Lightweight, durable, and moisture-resistant. Can be difficult to work with and may not be suitable for all applications.

- Insulated Concrete Forms (ICFs): Provide insulation and structural support, reducing energy costs and construction time. Can be more expensive than traditional formwork.

4. Explain the importance of proper concrete curing and its impact on the strength and durability of the structure?

- Hydration: Proper curing allows the concrete to fully hydrate, resulting in increased strength and durability.

- Strength Development: Curing provides the time necessary for the concrete to develop its maximum strength and load-bearing capacity.

- Durability: Curing reduces the risk of cracking, shrinkage, and other defects that can compromise the integrity of the structure.

5. How do you handle and store formwork materials to ensure their longevity and effectiveness?

- Storage: Store formwork materials in a dry, well-ventilated area, protected from moisture and extreme temperatures.

- Cleaning: Remove any concrete residue or debris from formwork panels after each use to prevent damage.

- Inspection: Regularly inspect formwork panels for any damage or wear and repair or replace as necessary.

- Oiling: Apply a release agent to formwork panels before each use to facilitate easy removal of concrete.

6. Describe the safety measures and regulations that must be followed when working with formwork?

- PPE: Wear appropriate personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and steel-toed boots.

- Fall Protection: Use ladders or scaffolding safely and securely when working at heights.

- Electrical Hazards: Be aware of electrical hazards and ensure that power tools are properly grounded.

- Material Handling: Follow proper lifting techniques to avoid injury when handling heavy formwork materials.

- Emergency Procedures: Know the location of emergency exits and evacuation procedures in case of an emergency.

7. How do you collaborate with other trades (e.g., carpenters, concrete finishers) to ensure a successful construction project?

- Communication: Maintain open communication with other trades to coordinate scheduling, material delivery, and installation.

- Coordination: Plan and sequence work activities to minimize disruptions and ensure a smooth handover between trades.

- Problem Solving: Work together to identify and resolve any issues or challenges that arise during the construction process.

- Quality Control: Collaborate to ensure that each trade meets the specified quality standards and requirements.

8. What are the key factors to consider when designing formwork for complex concrete structures?

- Structural Loads: Calculate and design the formwork to withstand the anticipated loads during concrete placement and curing.

- Concrete Pressure: Determine the hydrostatic pressure of the concrete and design the formwork accordingly.

- Access and Egress: Plan for safe and efficient access and egress points for workers to install, remove, and inspect the formwork.

- Complexity and Geometry: Consider the complexity and geometry of the structure to select the most suitable formwork system and materials.

9. How do you use technology and specialized equipment to enhance the efficiency and accuracy of formwork construction?

- Laser Levels: Use laser levels for precise leveling and alignment of formwork structures.

- Total Stations: Employ total stations for accurate measurements and positioning of formwork.

- 3D Modeling Software: Utilize 3D modeling software to design and visualize complex formwork systems.

- Hydraulic Jacks: Use hydraulic jacks for precise adjustment and leveling of formwork components.

10. Describe your approach to working under tight deadlines while maintaining high standards of quality?

- Planning and Coordination: Plan and coordinate tasks efficiently to ensure timely completion without compromising quality.

- Prioritization: Prioritize tasks based on their importance and impact on the overall project schedule.

- Communication: Communicate clearly with the team and stakeholders to manage expectations and address any potential delays.

- Continuous Improvement: Seek opportunities to streamline processes and improve efficiency while upholding quality standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Form Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Form Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Form workers play a crucial role in construction projects, ensuring the proper installation of concrete forms. Their key responsibilities encompass:1. Form Building and Assembly

Assembling, erecting, and aligning concrete forms according to blueprints and specifications.

- Selecting and installing form materials such as plywood, steel, and plastic.

- Using tools and machinery to cut, shape, and join form components precisely.

2. Form Preparation

Preparing forms for concrete placement by cleaning, oiling, and reinforcing them.

- Applying release agents to prevent concrete from sticking to forms.

- Installing reinforcement bars, wire mesh, or rebar to strengthen the concrete structure.

3. Concrete Placement Supervision

Ensuring proper concrete placement and consolidation within the constructed forms.

- Monitoring concrete pouring process to prevent voids or defects.

- Using vibrators to compact concrete and remove air bubbles.

4. Form Removal and Clean-up

Stripping forms after concrete has cured, cleaning and repairing them for reuse.

- Using hammers, pry bars, or hydraulic jacks to remove forms safely.

- Inspecting forms for damage and making necessary repairs or replacements.

Interview Tips

To ace a job interview for a Form Worker position, consider the following preparation tips:1. Research the Company and Role

Thoroughly research the construction company and the specific Form Worker role. Understand their project portfolio, industry experience, and reputation.

- Visit the company website, read online reviews, and check industry news.

- Identify the key responsibilities and qualifications required for the position.

2. Showcase Relevant Skills

Emphasize your practical skills in form building, concrete placement, and form removal. Provide specific examples from your previous experience.

- Quantify your accomplishments, such as “Assembled and aligned 500 square feet of concrete forms within two days.”

- Highlight your knowledge of construction materials, building codes, and safety regulations.

3. Demonstrate Problem-Solving Abilities

Form workers often encounter challenges on construction sites. Demonstrate your ability to solve problems and make quick decisions.

- Provide examples where you identified and resolved issues related to form construction or concrete placement.

- Explain your approach to troubleshooting and finding practical solutions.

4. Emphasize Safety and Attention to Detail

Safety is paramount in construction. Highlight your commitment to safety protocols and your attention to detail when performing form work tasks.

- Describe your experience with fall protection, equipment inspections, and hazard identification.

- Explain how you ensure accuracy in form assembly and concrete placement.

5. Prepare Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions specific to the company, the project, or the Form Worker position.

- Example questions: “Can you describe the safety protocols implemented on your construction sites?” or “What are the company’s plans for future projects that involve form work?”

- Prepare questions that demonstrate your enthusiasm for the opportunity and your commitment to the construction industry.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Form Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.