Are you gearing up for a career in Forming Machine Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Forming Machine Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

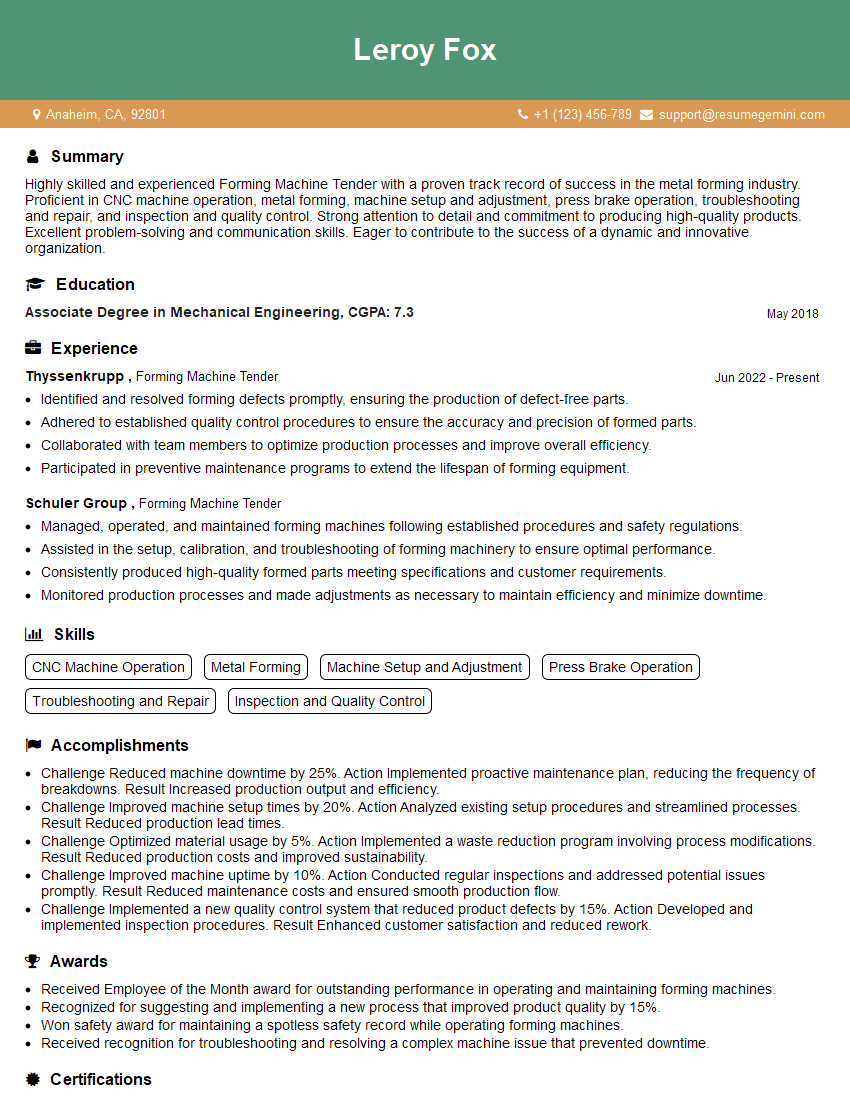

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forming Machine Tender

1. What are the different types of forming machines you have operated?

In my previous role as a Forming Machine Tender, I operated various types of forming machines, including press brakes, shearers, and rollers. I am proficient in setting up and operating these machines to produce high-quality parts according to specifications.

2. How do you ensure that the formed parts meet the required dimensions and tolerances?

Quality Control Checks

- I perform regular quality control checks throughout the forming process.

- I use measuring tools such as calipers, micrometers, and gauges to verify dimensions and ensure they meet specifications.

Machine Calibration

- Regularly calibrate the forming machines to maintain accuracy.

- This involves checking the machine’s alignment, pressure settings, and tooling.

Process Optimization

- Optimize the forming process by adjusting machine parameters and tooling.

- This helps reduce defects and improve part quality.

3. What are the safety precautions that you observe when operating forming machines?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, earplugs, and gloves.

- Follow lockout/tagout procedures when servicing or cleaning machines.

- Maintain a clean and organized work area to prevent tripping hazards.

- Be aware of pinch points and moving parts, and keep hands clear.

- Report any unsafe conditions or equipment malfunctions immediately.

4. How do you troubleshoot common problems that arise during the forming process?

- Identify the problem and determine its potential causes.

- Check machine settings, tooling, and material to identify any issues.

- Make necessary adjustments or repairs to resolve the problem.

- Document the problem and corrective actions taken for future reference.

5. What is your experience with different types of materials used in forming?

- Experience working with a variety of materials, including steel, aluminum, brass, and plastics.

- Understand the properties and characteristics of each material, and how they affect the forming process.

6. What techniques do you use to minimize material waste during the forming process?

- Optimize material usage by selecting the most efficient cutting and forming methods.

- Use scrap material for smaller parts or prototypes.

- Implement lean manufacturing principles to reduce waste and improve efficiency.

7. How do you maintain and clean forming machines to ensure optimal performance?

- Regularly clean and lubricate machines according to manufacturer’s instructions.

- Inspect machines for wear and tear, and replace worn parts as needed.

- Maintain a clean and organized work area to prevent contamination.

8. What is your understanding of the role of Computer Numerical Control (CNC) in forming machines?

- Understand the basics of CNC programming and its application in forming machines.

- Follow CNC programs to produce accurate and consistent parts.

- Troubleshoot and resolve any issues with CNC programs or equipment.

9. How do you stay up-to-date with the latest advancements in forming technology?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Network with other forming professionals.

10. Describe a challenging project you worked on as a Forming Machine Tender and how you overcame the challenges?

Project Description

- Formed complex parts for a new product launch.

- Tight tolerances and intricate designs.

Challenges Faced

- Material was prone to deformation.

- Limited tooling options available.

Solutions Implemented

- Modified forming process to reduce deformation.

- Designed and fabricated custom tooling to meet specific requirements.

- Collaborated with engineers to optimize machine settings.

Outcome

- Successfully produced parts that met specifications.

- Reduced production time and improved efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forming Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forming Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Forming Machine Tenders are responsible for operating and maintaining forming machines that produce a variety of metal and plastic products. They must be able to read and interpret blueprints and specifications, and have a basic understanding of the machine’s operation.

1. Operating Forming Machine

Forming Machine Tenders use forming machines to create a variety of products, including metal and plastic components, automotive parts, and appliances. They must be able to set up the machine, load the material, and operate the machine correctly in order to produce a quality product.

- Set up and operate forming machines to create metal and plastic products.

- Load and unload materials from the machine.

- Monitor the machine’s operation and make adjustments as needed.

2. Maintaining Forming Machine

Forming Machine Tenders are also responsible for maintaining their machines. They must be able to identify and troubleshoot problems, and perform basic repairs. They must also keep the machine clean and lubricated.

- Identify and troubleshoot problems with the machine.

- Perform basic repairs on the machine.

- Keep the machine clean and lubricated.

3. Inspecting Products

Forming Machine Tenders are responsible for inspecting the products produced by their machines. They must be able to identify defects and ensure that the products meet specifications.

- Inspect products for defects.

- Ensure that products meet specifications.

- Reject products that do not meet specifications.

4. Maintaining a Safe Work Environment

Forming Machine Tenders must be able to maintain a safe work environment. They must be aware of the hazards associated with their work and take precautions to avoid accidents.

- Follow safety procedures.

- Wear appropriate safety gear.

- Report any safety hazards to their supervisor.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Forming Machine Tender position:

1. Research the Company and the Position

Before the interview, take some time to research the company and the position. This will help you understand the company’s culture and values, and what they are looking for in a Forming Machine Tender.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work at the company.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Use the STAR method to answer interview questions.

- Prepare examples of your skills and experience that are relevant to the position.

- Practice answering questions with a friend or family member.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire.

- Arrive for your interview at least 10 minutes early.

- Be polite and respectful to everyone you meet.

4. Be Yourself and Be Confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest about your skills and experience, and be confident in your ability to do the job.

- Be honest about your skills and experience.

- Be confident in your ability to do the job.

- Be yourself and let the interviewer get to know the real you.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Forming Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.