Feeling lost in a sea of interview questions? Landed that dream interview for Forming Press Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Forming Press Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

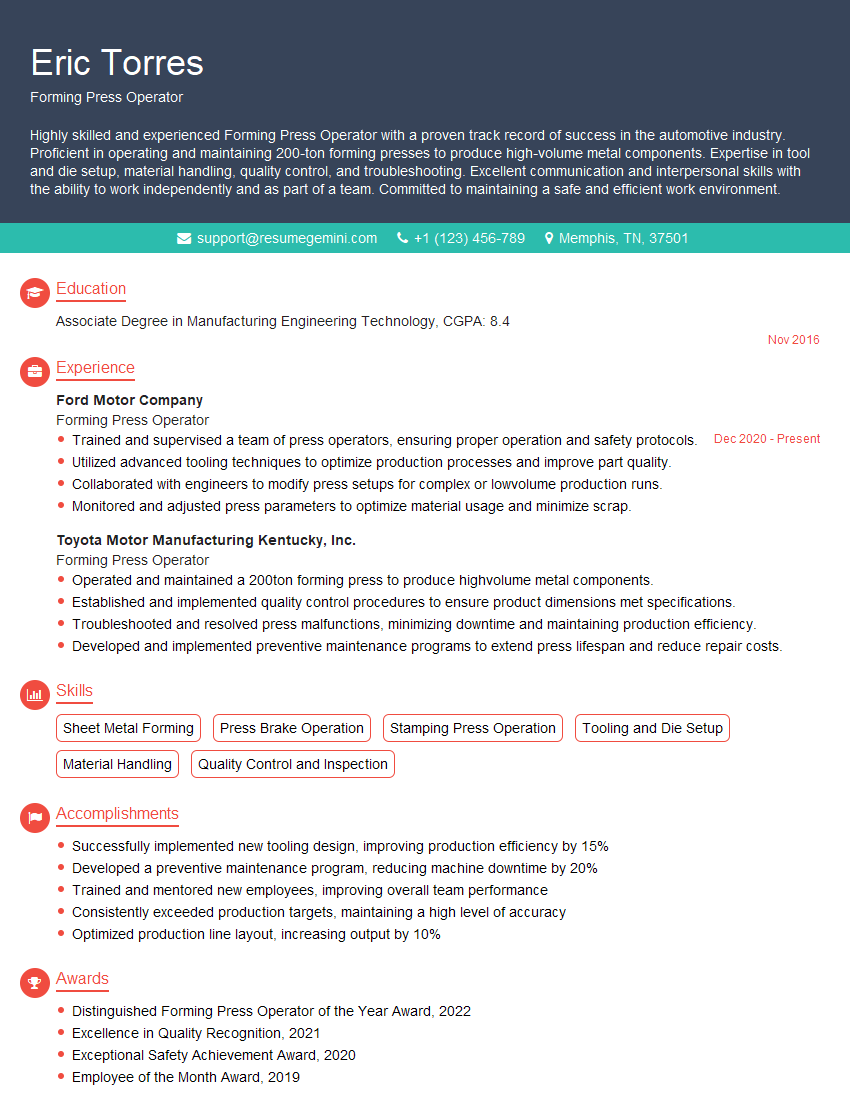

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forming Press Operator

1. What are the critical operations and procedures that you follow when operating a forming press?

In my previous role as a Forming Press Operator, I consistently adhered to stringent operating procedures to ensure efficient and safe press operation. These included:

- Properly securing dies and workpiece before starting the press cycle

- Monitoring pressure and temperature settings to maintain optimal forming conditions

- Performing regular inspections and adjustments to maintain equipment accuracy

- Following established safety protocols, including wearing appropriate PPE and observing lockout/tagout procedures

2. How do you handle situations where the forming press malfunctions or produces defective parts?

Troubleshooting and Maintenance

- Identify and isolate the source of the malfunction through visual inspection and diagnostic tools

- Perform basic troubleshooting steps, such as checking electrical connections and resetting controls

- Notify maintenance personnel if the issue cannot be resolved immediately

Quality Control

- Inspect parts for defects using gauges and measurement tools

- Identify and isolate the cause of defects based on process parameters and part characteristics

- Make adjustments to the press settings or other factors to eliminate defects

3. Describe the role of tooling in the forming process and how you ensure its proper maintenance and storage.

Tooling plays a crucial role in the forming process, and its proper maintenance is essential for producing high-quality parts. I take the following steps to ensure tooling integrity:

- Inspect tooling regularly for wear, damage, or misalignment

- Clean and lubricate tooling as per manufacturer’s recommendations

- Store tooling properly in designated racks or cases to prevent damage

- Follow established procedures for changing and adjusting tooling to ensure proper alignment and operation

4. How do you optimize the forming process to achieve maximum efficiency and minimize waste?

Optimizing the forming process is essential for increasing productivity and reducing costs. I employ the following strategies:

- Analyze process parameters, such as pressure, temperature, and cycle time, to identify areas for improvement

- Implement lean manufacturing techniques, such as 5S and Kaizen, to reduce waste and streamline operations

- Monitor production data and identify bottlenecks or inefficiencies

- Collaborate with engineers and technicians to make adjustments to the process or equipment to enhance efficiency

5. What is the importance of maintaining a clean and organized work area, and how do you ensure that your workplace meets safety standards?

A clean and organized work area is crucial for both safety and productivity. I adhere to the following practices:

- Keep the work area free of clutter and debris to prevent tripping hazards

- Ensure proper ventilation to minimize exposure to fumes or dust

- Organize tooling and materials in designated areas to facilitate easy access

- Comply with all safety protocols, including wearing appropriate PPE, following lockout procedures, and reporting any potential hazards

6. How do you stay updated on industry best practices and technological advancements in forming press operations?

To stay current with industry best practices and technological advancements, I actively engage in the following activities:

- Attend industry conferences and workshops to learn about new techniques and equipment

- Read trade publications and technical journals to stay informed about emerging technologies

- Network with other professionals in the field to exchange knowledge and experiences

7. How do you handle working in a team environment and collaborate with other members of the production line?

I am a team player and have demonstrated strong collaboration skills in previous roles. I believe in open communication and actively contribute to team discussions and problem-solving sessions. I am adept at coordinating with other team members to ensure smooth production flow and maintain a positive work environment.

8. What motivates you to perform your job to the best of your ability, and what do you find most rewarding about working as a Forming Press Operator?

I am motivated by the precision and technical challenges of forming press operation. I find it rewarding to produce high-quality parts that meet specifications and contribute to the successful operation of the production line. Additionally, I enjoy working as part of a team and contributing to the overall success of the organization.

9. What strategies do you use to prevent and mitigate potential hazards associated with forming press operations?

Safety is paramount in my work. I employ the following strategies to prevent and mitigate potential hazards:

- Thoroughly understand and follow all safety protocols and procedures

- Inspect equipment regularly and report any potential issues

- Wear appropriate PPE at all times

- Maintain a clean and organized work area

- Be aware of surroundings and potential hazards

10. Describe a project or initiative you were involved in that improved the efficiency or quality of a forming press operation. What were your key contributions?

In my previous role, I led a project to implement lean manufacturing techniques on the forming press line. By analyzing process parameters and implementing 5S principles, we were able to reduce cycle time by 15% and improve product quality by 10%. My key contributions included:

- Identifying areas for improvement through process mapping and data analysis

- Developing and implementing standard operating procedures

- Training operators on new procedures and monitoring their progress

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forming Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forming Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Forming press operators are essential members of the manufacturing industry, responsible for operating and maintaining forming presses that shape and mold various materials.

1. Operating Forming Presses

The primary duty of a forming press operator involves setting up, operating, and monitoring forming presses to produce parts according to specifications.

- Adjusting press settings and tooling to ensure optimal performance

- Loading and unloading materials into and out of the press

- Observing the press operation and making necessary adjustments to maintain quality

2. Quality Control

Operators are responsible for checking the quality of parts produced by the press, ensuring they meet the required specifications.

- Measuring and inspecting parts using appropriate tools and gauges

- Maintaining records of production data, including quality control results

- Identifying and resolving any quality issues that arise during the production process

3. Machine Maintenance

Operators must perform routine maintenance tasks to ensure the smooth functioning of the forming press, preventing breakdowns and downtime.

- Lubricating and cleaning the press components

- Inspecting and replacing worn or damaged parts

- Troubleshooting and resolving minor mechanical issues

4. Safety Compliance

Operating forming presses can involve hazardous conditions, requiring strict adherence to safety protocols.

- Wearing appropriate personal protective equipment, including safety glasses, gloves, and hearing protection

- Following established safety procedures and guidelines

- Maintaining a clean and organized work area

Interview Tips

To ace an interview for a forming press operator position, it is crucial to showcase your technical skills, problem-solving abilities, and commitment to safety.

1. Research the Company and Industry

Demonstrate your interest in the company and the forming press industry by researching their products, services, and recent developments.

- Visit the company website and LinkedIn page

- Read industry publications and articles

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating forming presses, including experience with different types of presses and tooling.

- Quantify your accomplishments using specific metrics and examples

- Explain how your experience has developed your problem-solving and decision-making abilities

3. Demonstrate a Strong Safety Mindset

Safety is paramount in forming press operations. Highlight your commitment to safety and your understanding of safety protocols.

- Describe your experience with following safety procedures and your role in maintaining a safe work environment

- Explain how you stay updated on industry safety standards and best practices

4. Prepare for Technical Questions

Expect technical questions related to forming press operations, including:

- Different types of forming presses and their applications

- Material properties and their impact on forming processes

- Troubleshooting common press issues

5. Practice Answering Behavioral Questions

Behavioral questions assess your approach to work and your problem-solving skills.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Provide specific examples that demonstrate your abilities and work style

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Forming Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!