Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Forming Roll Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

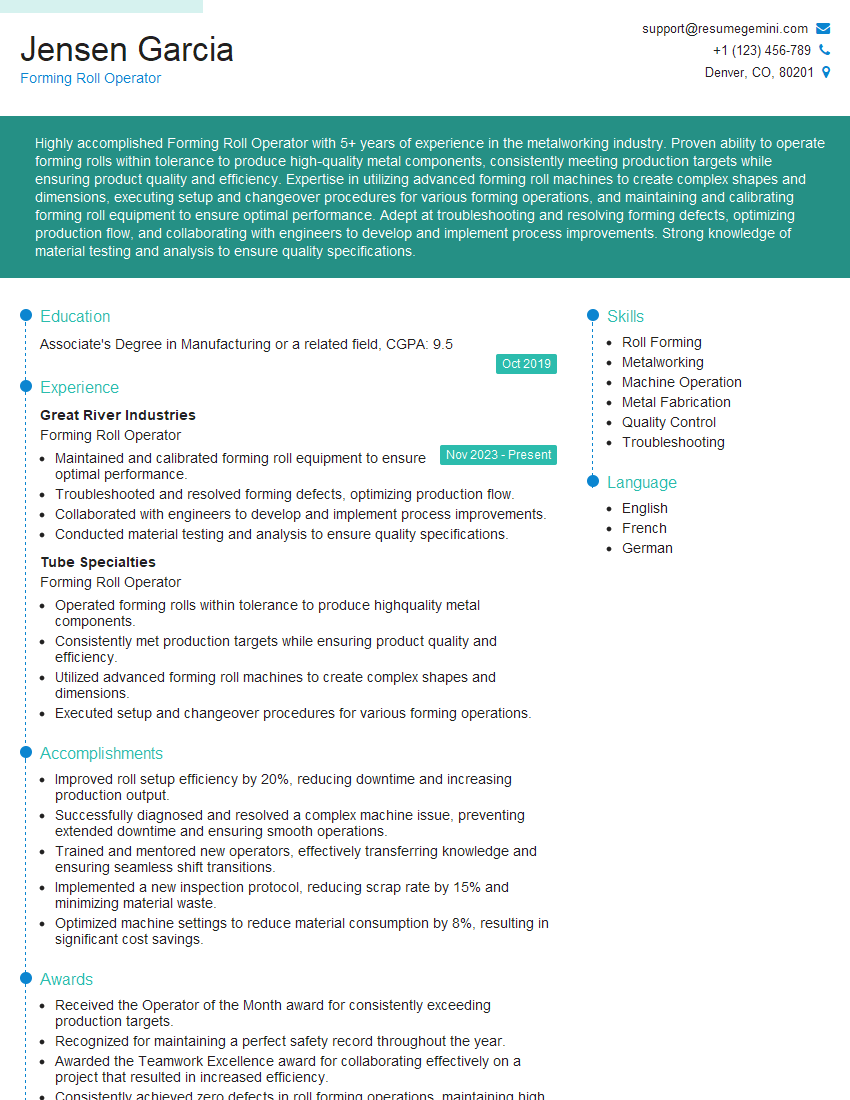

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forming Roll Operator

1. Explain the process of setting up a forming roll machine for a specific profile?

A Forming Roll Operator is responsible for setting up and operating a forming roll machine to produce metal profiles. The setup process involves several steps to ensure the machine is correctly configured for the desired profile.

- Review the order specifications: The operator reviews the order to understand the required profile dimensions, material thickness, and any other specific requirements.

- Select and install the appropriate forming rolls: The operator selects the correct forming rolls based on the profile specifications and installs them in the machine.

- Adjust the roll gap and tension: The operator adjusts the gap between the forming rolls and sets the tension on the material to ensure proper forming without buckling or tearing.

- Calibrate the machine: The operator runs a test piece through the machine to calibrate the settings and ensure the desired profile is produced.

- Monitor and make adjustments: Once the setup is complete, the operator monitors the machine during operation and makes necessary adjustments to maintain the desired profile and quality.

2. How do you maintain and troubleshoot a forming roll machine?

Regular maintenance: The operator performs regular maintenance tasks such as cleaning the machine, lubricating moving parts, and checking the condition of the forming rolls and other components.

Troubleshooting: In case of any issues or malfunctions, the operator follows established troubleshooting procedures to identify and resolve the problem. This may involve checking electrical connections, inspecting mechanical components, or adjusting settings.

Calibration: The operator regularly calibrates the machine to ensure accuracy and consistency in the produced profiles.

3. What are the safety protocols you follow when operating a forming roll machine?

Safety is paramount when operating a forming roll machine. The operator must adhere to the following protocols:

- Wear appropriate PPE: This includes safety glasses, gloves, and hearing protection.

- Keep the work area clear: Ensure there are no obstacles or tripping hazards around the machine.

- Inspect the machine before operation: Check for any loose parts, electrical hazards, or damaged components.

- Follow lockout/tagout procedures: Lock out and tag out the machine before performing any maintenance or repairs.

- Never reach into the machine while it is running: Use tools or a stick to retrieve materials or make adjustments.

4. How do you ensure the quality of the formed profiles?

Ensuring the quality of formed profiles requires a combination of attention to detail and adherence to quality control procedures:

- Regular inspections: The operator regularly inspects the formed profiles for any defects, such as scratches, dents, or dimensional inaccuracies.

- Measurement verification: The operator uses measuring tools to verify the dimensions of the profiles against the specifications.

- Material checks: The operator checks the material thickness and quality to ensure it meets the required standards.

- Maintenance and calibration: Regular maintenance and calibration of the machine help ensure consistent quality and accuracy.

5. How do you optimize the production process to minimize waste and increase efficiency?

Material optimization: The operator uses nesting techniques to minimize material waste during cutting.

Efficient machine setup: Proper setup and calibration reduce the need for rework and downtime.

Preventative maintenance: Regular maintenance helps prevent breakdowns and keeps the machine running smoothly.

Training and teamwork: Well-trained operators and effective teamwork contribute to increased productivity and reduced errors.

6. Describe the different types of forming roll machines and their applications?

There are various types of forming roll machines, each designed for specific applications:

- Plate roll machines: Used to roll and shape thick metal plates into cylindrical or conical shapes.

- Section roll machines: Used to produce complex profiles, such as structural beams, channels, and angles.

- Tube roll machines: Used to form tubes from flat metal strips.

- Slitting roll machines: Used to cut metal sheets into narrow strips.

- Corrugating roll machines: Used to create corrugated metal sheets for roofing and siding.

7. How do you handle and store forming rolls to ensure their longevity?

- Proper handling: Rolls should be handled with care to avoid damage from impacts or dropping.

- Storage conditions: Rolls should be stored in a dry, climate-controlled environment to prevent corrosion.

- Protective coatings: Rolls can be coated with rust-preventive agents to enhance their durability.

8. How do you adjust and maintain the tension of the material during the forming process?

- Tension adjustment: The operator uses tension control devices to adjust the tension applied to the material during forming.

- Tension monitoring: The operator monitors the tension using sensors or gauges to ensure it remains within the specified range.

- Tension maintenance: Regular adjustments and maintenance of tension control systems ensure consistent tension throughout the forming process.

9. Explain how you use measuring and inspection tools to ensure the accuracy of formed profiles?

- Measuring tools: The operator uses micrometers, calipers, and other measuring tools to verify the dimensions of the formed profiles.

- Inspection tools: The operator uses visual inspection, gauges, and templates to check for defects, surface finish, and overall quality.

- Calibration: The operator regularly calibrates measuring and inspection tools to ensure their accuracy and reliability.

10. How do you troubleshoot and resolve common issues that arise during the forming process?

- Problem identification: The operator observes the forming process and identifies any deviations from normal operation.

- Cause analysis: The operator analyzes the potential causes of the issue, considering factors such as material properties, machine settings, and environmental conditions.

- Solution implementation: The operator implements appropriate corrective actions to resolve the issue, such as adjusting machine parameters, replacing worn components, or modifying the forming process.

- Verification: The operator verifies that the issue has been resolved and the forming process is operating correctly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forming Roll Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forming Roll Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Forming Roll Operators are responsible for operating and maintaining forming roll machines to produce metal sheets, strips, and other metal products. They ensure that the machines are operating efficiently and safely, and that the products meet the required specifications.

1. Operating Forming Roll Machines

Forming Roll Operators monitor and control the operation of forming roll machines to produce metal products with the desired shape and dimensions. They adjust the machine settings, such as speed, pressure, and temperature, to achieve the desired results.

- Set up and adjust forming roll machines according to specifications.

- Load and unload metal coils onto the machines.

- Thread metal coils through the forming rolls.

- Monitor the operation of the machines to ensure that they are running smoothly.

- Make adjustments to the machines as needed to maintain the desired product quality.

2. Inspecting Metal Products

Forming Roll Operators inspect the finished metal products to ensure that they meet the required specifications. They check for defects such as scratches, dents, and burrs.

- Visually inspect metal products for defects.

- Measure the dimensions of the products to ensure that they meet specifications.

- Reject any products that do not meet specifications.

3. Maintaining Forming Roll Machines

Forming Roll Operators are responsible for maintaining the forming roll machines to ensure that they are operating safely and efficiently. They perform regular maintenance tasks, such as cleaning, lubrication, and repairs.

- Clean and lubricate the forming roll machines.

- Inspect the machines for wear and tear.

- Perform minor repairs to the machines.

- Report any major repairs that are needed.

4. Following Safety Procedures

Forming Roll Operators must follow all safety procedures to ensure their own safety and the safety of others. They wear appropriate personal protective equipment, such as gloves, safety glasses, and earplugs.

- Wear appropriate personal protective equipment.

- Follow all safety procedures.

- Report any unsafe conditions.

Interview Tips

Preparing for an interview can be daunting, but with the right tips and tricks, you can increase your chances of success. Here are some interview tips for Forming Roll Operators:

1. Research the company and the position

Before you go into an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals. It will also help you to tailor your answers to the interviewer’s questions.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice answering these questions so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Be prepared to talk about your skills and experience.

- Be prepared to answer questions about your availability.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace. You should also make sure to arrive on time for your interview and be prepared to shake the interviewer’s hand.

- Wear a suit or business casual attire.

- Be clean and well-groomed.

- Arrive on time for your interview.

4. Be confident and enthusiastic

Interviewers are looking for candidates who are confident and enthusiastic about the position. Make sure to maintain eye contact with the interviewer and speak clearly and confidently. You should also be prepared to ask questions about the position and the company.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Ask questions about the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Forming Roll Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!