Are you gearing up for a career in Foundry Finisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Foundry Finisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

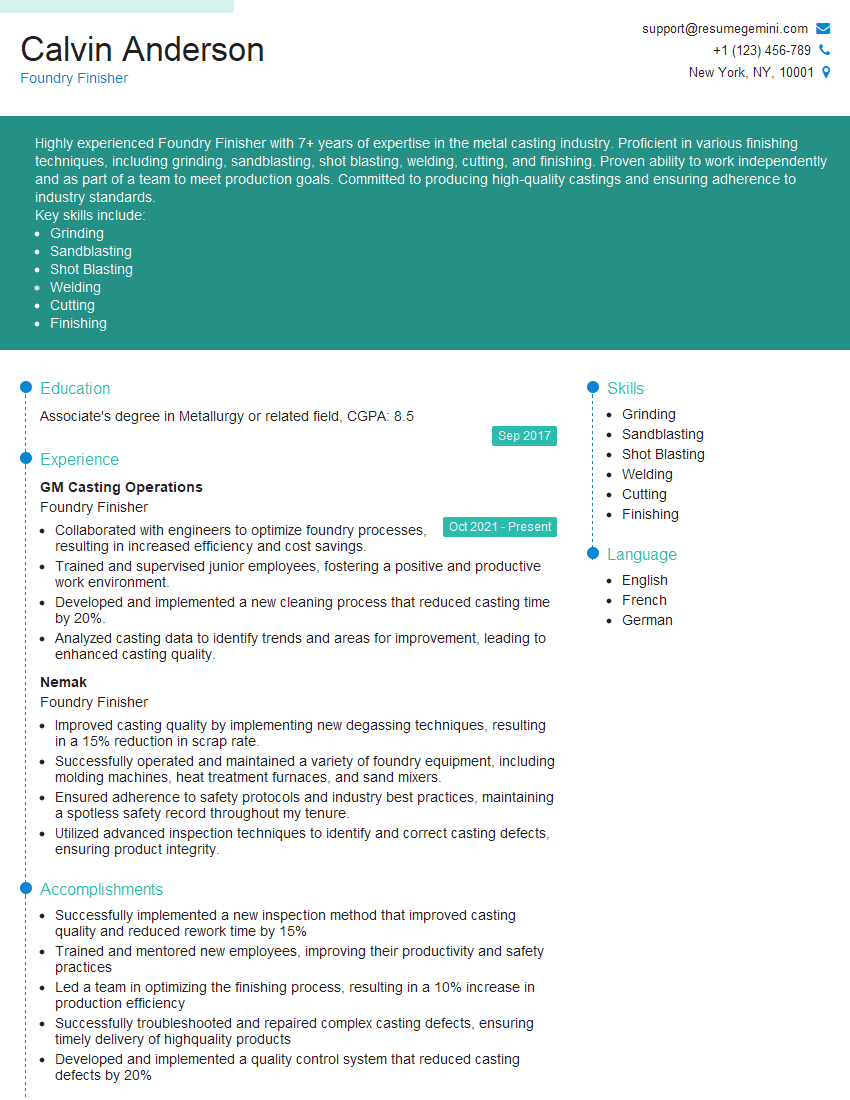

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Finisher

1. Describe the different types of finishes that can be applied to castings?

There are several types of finishes that can be applied to castings, including:

- Mechanical finishes: These finishes are created by machining or grinding the surface of the casting to remove imperfections and achieve the desired surface roughness.

- Chemical finishes: These finishes are created by applying a chemical solution to the surface of the casting to dissolve the metal and create a smooth, corrosion-resistant surface.

- Electrolytic finishes: These finishes are created by passing an electric current through the casting to deposit a thin layer of metal on the surface. This can provide a protective or decorative finish.

- Conversion coatings: These finishes are created by applying a chemical solution to the surface of the casting to form a thin, protective layer of oxide or phosphate.

2. What are the key factors to consider when selecting a finish for a casting?

Factors that influence finish selection

- The intended use of the casting

- The environment in which the casting will be used

- The desired appearance of the casting

- The cost of the finish

Example of finish selection considerations

- A casting that will be used in a corrosive environment may require a chemical or electrolytic finish to provide protection against corrosion.

- A casting that will be used in a high-wear application may require a mechanical finish to provide a hard, wear-resistant surface.

- A casting that will be used in a decorative application may require a finish that provides a specific color or texture.

3. How do you ensure that the finished surface meets the required specifications?

To ensure that the finished surface meets the required specifications, I would follow these steps:

- Review the casting drawing and specifications to understand the required surface finish.

- Select the appropriate finishing process and equipment.

- Set up the finishing equipment according to the manufacturer’s instructions.

- Test the finishing process on a sample casting to ensure that the desired finish is being achieved.

- Monitor the finishing process to ensure that the desired finish is being consistently achieved.

- Inspect the finished castings to ensure that they meet the required specifications.

4. What are the common defects that can occur during the finishing process, and how do you prevent them?

Some common defects that can occur during the finishing process include:

- Surface roughness: This can be caused by improper machining or grinding techniques, or by using the wrong type of abrasive.

- Burrs: These are small, sharp edges that can be created during machining or grinding. They can be removed by deburring the casting.

- Corrosion: This can be caused by exposure to moisture or other corrosive agents. It can be prevented by applying a protective finish to the casting.

- Pitting: This is a type of corrosion that can cause small pits or holes to form in the surface of the casting. It can be prevented by using a corrosion-resistant finish.

To prevent these defects, it is important to use the correct finishing techniques and equipment, and to follow the manufacturer’s instructions.

5. What are the safety precautions that must be taken when working with finishing equipment?

When working with finishing equipment, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as safety glasses, gloves, and a dust mask.

- Operate the equipment according to the manufacturer’s instructions.

- Keep the work area clean and free of debris.

- Be aware of the potential for electrical hazards.

- Follow all lockout/tagout procedures.

6. What are the latest trends in finishing technology?

Some of the latest trends in finishing technology include:

- Automated finishing systems: These systems use robots or other automated equipment to perform finishing tasks, which can improve efficiency and reduce labor costs.

- Laser finishing: This technology uses lasers to remove material from the surface of a casting, which can create a smooth, precise finish.

- Environmentally friendly finishes: These finishes are designed to minimize the environmental impact of the finishing process, such as by reducing the use of hazardous chemicals.

7. How do you keep up with the latest developments in finishing technology?

To keep up with the latest developments in finishing technology, I:

- Read trade publications and attend industry conferences.

- Network with other finishing professionals.

- Attend training courses offered by equipment manufacturers.

- Experiment with new finishing techniques and materials.

8. What are your strengths and weaknesses as a foundry finisher?

Strengths

- I have a strong understanding of the different finishing processes and materials.

- I am skilled in using a variety of finishing equipment.

- I am committed to quality and precision.

- I am a hard worker and I am always willing to learn new things.

Weaknesses

- I am relatively new to the foundry industry.

- I do not have experience with all types of finishing equipment.

9. Why are you interested in working as a foundry finisher?

I am interested in working as a foundry finisher because I am fascinated by the process of transforming raw metal into finished products. I am also tertarik by the opportunity to learn new skills and to work with a variety of materials and equipment.

10. What are your salary expectations?

My salary expectations are in line with the industry average for foundry finishers with my experience and skills. I am open to negotiating a salary that is fair and competitive.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foundry Finishers are responsible for ensuring the quality and precision of metal castings. They use a variety of tools and techniques to remove excess metal, smooth surfaces, and create intricate details. Key job responsibilities include:

1. Removing Excess Metal

Foundry Finishers use grinders, sanders, and other tools to remove excess metal from castings. They must be precise in their work to avoid damaging the casting or creating defects.

- Using a variety of power tools to remove excess metal and flash from castings.

- Deburring and smoothing castings to remove sharp edges and imperfections.

2. Smoothing Surfaces

Foundry Finishers use abrasives and other materials to smooth the surfaces of castings. They must be able to achieve a variety of finishes, from rough to polished.

- Polishing castings to achieve a desired finish.

- Using various abrasive materials to grind and smooth surfaces.

3. Creating Intricate Details

Foundry Finishers use a variety of tools and techniques to create intricate details on castings. They must be able to work with a high degree of precision and accuracy.

- Using specialized tools to create intricate details on castings.

- Inspecting castings for quality and accuracy.

4. Ensuring Quality

Foundry Finishers are responsible for ensuring the quality of castings. They must be able to identify and correct defects, and they must be able to meet customer specifications.

- Ensuring castings meet quality standards and specifications.

- Maintaining a clean and organized work area.

Interview Tips

Preparing for a Foundry Finisher interview can be daunting, but with the right approach, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and Position

Before your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website to learn about their history, products, and services.

- Read industry publications and articles to stay up-to-date on the latest trends.

- Network with people in your field to learn about potential job openings.

2. Practice Your Answers

Once you’ve done your research, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Use the STAR method to answer questions about your experience.

- Be specific and provide examples to support your answers.

- Prepare questions to ask the interviewer.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Men should wear a suit or dress pants and a button-down shirt.

- Women should wear a dress, skirt, or pantsuit.

- Make sure your clothes are clean and pressed.

4. Be On Time

Punctuality is important for any interview, but it’s especially important for a Foundry Finisher interview. This is because foundries are often busy and time-sensitive environments.

- Arrive at the interview location on time or even a few minutes early.

- If you’re running late, call or email the interviewer to let them know.

- Being on time shows that you’re respectful of the interviewer’s time.

5. Be Enthusiastic and Positive

Foundry Finishers are often passionate about their work, so it’s important to show the interviewer that you’re enthusiastic about the job. Be positive and upbeat during your interview, and make sure to highlight your skills and experience.

- Share your passion for foundry work.

- Highlight your skills and experience.

- Be positive and upbeat.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Foundry Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!