Are you gearing up for a career in Foundry Mold Assembly and Shake-Out Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Foundry Mold Assembly and Shake-Out Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

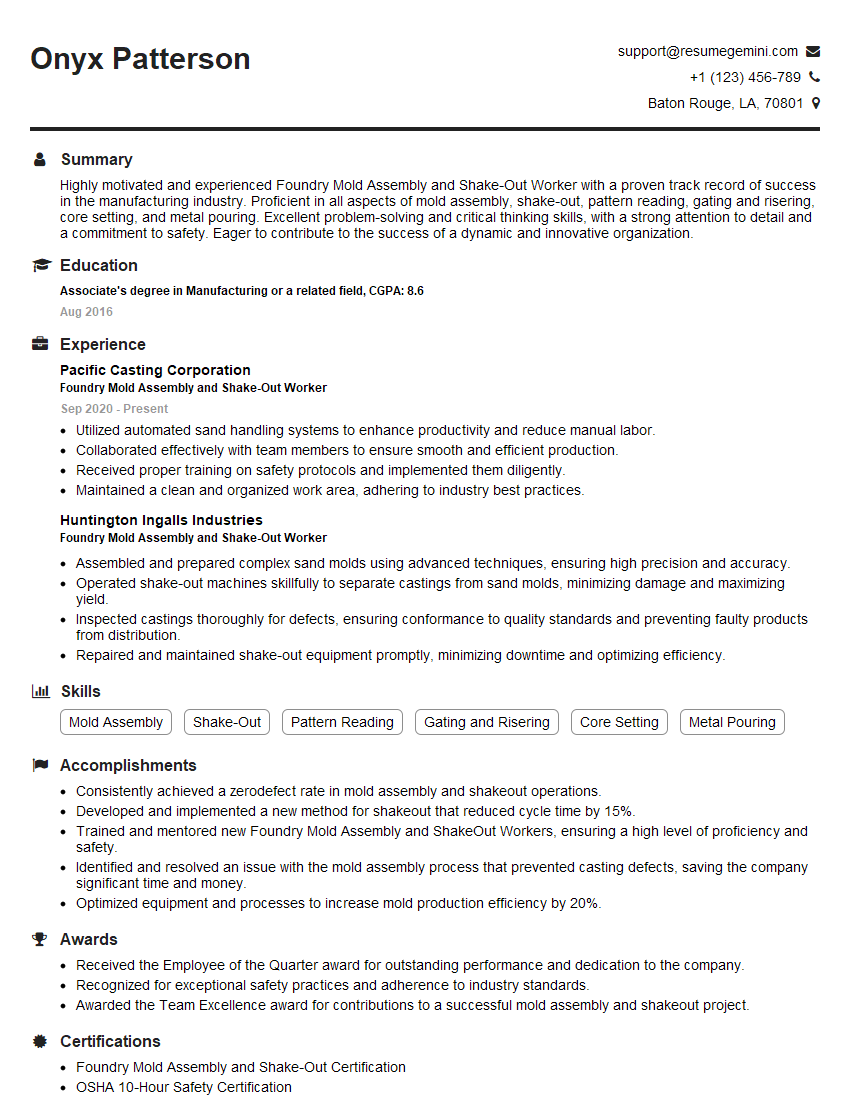

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Mold Assembly and Shake-Out Worker

1. Describe the steps involved in assembling a foundry mold.

The steps involved in assembling a foundry mold include:

- Preparing the pattern by cleaning and applying release agent.

- Making the cope and drag flasks by filling them with sand and packing it tightly.

- Setting the pattern in the drag flask and filling the remaining space with sand, followed by securing the cope flask on top.

- Creating the gating system to allow molten metal to enter the mold cavity.

- Clamping the flasks together and pouring molten metal into the mold.

2. Explain the shake-out process in detail, including the equipment and safety precautions to be taken.

Equipment used:

- Shake-out grate or table

- Vibrating shake-out machine

- Rakes and shovels

Safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Ensure that the shake-out area is well-ventilated.

- Operate the shake-out machine according to manufacturer’s instructions.

- Be aware of potential hazards such as falling objects and hot castings.

3. What is the purpose of using a parting agent in mold making?

A parting agent is used in mold making to create a barrier between the pattern and the sand, preventing them from sticking together. This allows for easy separation of the pattern from the mold after the mold has been created.

4. How do you ensure the accuracy and quality of the molds you produce?

I ensure the accuracy and quality of the molds I produce by:

- Following all established procedures and specifications.

- Using precision measuring tools and equipment.

- Inspecting molds at critical stages of the process.

- Receiving feedback from experienced colleagues and supervisors.

5. Describe the different types of sand used in foundry molds.

The different types of sand used in foundry molds include:

- Silica sand: Most common type, provides good strength and permeability.

- Zircon sand: More expensive than silica sand, offers higher thermal resistance.

- Chromite sand: Used for heavy castings due to its high strength and resistance to abrasion.

- Olivine sand: Suitable for steel castings due to its resistance to molten metal erosion.

6. What are the common defects that can occur in foundry molds and how can they be prevented?

Common defects in foundry molds include:

- Shrinkage cavities: Prevented by using proper risers and chills.

- Gas porosity: Prevented by using additives to reduce gas formation and ensuring proper ventilation.

- Sand inclusions: Prevented by using clean sand and proper molding techniques.

- Cracks: Prevented by using proper mold materials and avoiding thermal stresses.

7. What are the environmental regulations that apply to foundry operations, specifically related to mold assembly and shake-out?

Environmental regulations applicable to foundry operations include:

- Air quality regulations to control dust and emissions.

- Waste management regulations for the disposal of spent sand and other materials.

- Water quality regulations to prevent contamination from foundry wastewater.

8. Explain the importance of proper maintenance and calibration of equipment used in mold assembly and shake-out.

Proper maintenance and calibration of equipment is crucial because it:

- Ensures accurate and consistent mold production.

- Prevents equipment failures and costly downtime.

- Promotes safety by preventing malfunctions and accidents.

- Extends the lifespan of the equipment.

9. Describe your experience in troubleshooting mold assembly and shake-out issues.

In my previous role, I was responsible for troubleshooting and resolving various issues related to mold assembly and shake-out, such as:

- Identifying and fixing mold defects that affected casting quality.

- Adjusting equipment settings to optimize efficiency and minimize waste.

- Implementing corrective measures to address environmental concerns.

- Collaborating with maintenance personnel to resolve equipment malfunctions and improve performance.

10. How do you prioritize your tasks and manage your time effectively in a fast-paced foundry environment?

In a fast-paced foundry environment, I prioritize my tasks based on urgency and importance, ensuring that critical tasks are completed first. I also use effective time management techniques, such as:

- Creating daily to-do lists and setting priorities.

- Breaking down large tasks into smaller, manageable steps.

- Delegating tasks when possible to optimize efficiency.

- Minimizing distractions and focusing on completing tasks without interruptions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Mold Assembly and Shake-Out Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Mold Assembly and Shake-Out Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Foundry Mold Assembly and Shake-Out Worker is responsible for assembling and shaking out molds in a foundry. The primary duties of this role include:

1. Mold Assembly

Assemble and secure molds according to specified blueprints and work orders.

- Position and align mold components, including flasks, patterns, and cores.

- Secure components using clamps, bolts, or other fasteners.

2. Mold Handling

Transport and handle molds safely using forklifts, cranes, or other equipment.

- Move molds from the molding area to the pouring station.

- Handle and position molds during pouring and cooling processes.

3. Shake-Out

Separate castings from molds using a shake-out machine or manual tools.

- Operate shake-out equipment to remove sand and debris from castings.

- Manually clean castings using brushes, scrapers, or other tools.

4. Inspection and Quality Control

Inspect castings for defects and ensure they meet quality standards.

- Identify and mark castings with defects.

- Maintain records of mold assembly and shake-out operations.

Interview Tips and Preparation

To ace the interview for the Foundry Mold Assembly and Shake-Out Worker position, candidates should:

1. Research the Company and Industry

Gather information about the foundry, its products, and the industry. This knowledge will demonstrate your interest and understanding of the role.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Highlight Relevant Skills and Experience

Emphasize your experience in mold assembly, shake-out operations, and foundry safety practices. Quantify your accomplishments whenever possible.

- Use specific examples to demonstrate your abilities in assembling and disassembling molds.

- Share your experience in operating shake-out equipment or using manual cleaning tools.

3. Communicate Safety Awareness

Foundry work involves potential hazards, so it is crucial to convey your understanding of safety protocols.

- Discuss your training and experience in following safety regulations.

- Highlight your awareness of common foundry hazards and proper protective gear.

4. Show Physical Fitness

This role requires physical strength and stamina. Prepare to discuss your ability to lift heavy molds, handle equipment, and work in a demanding environment.

- Provide examples of physically demanding tasks you have performed in previous roles.

- Emphasize your willingness to work in a fast-paced and physically challenging setting.

5. Practice Common Interview Questions

Prepare for typical interview questions, such as:

- “Tell me about your experience in foundry mold assembly and shake-out operations.”

- “What safety measures do you take when working in a foundry environment?”

- “How do you handle the physical demands of this role?”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Foundry Mold Assembly and Shake-Out Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Foundry Mold Assembly and Shake-Out Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.