Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Foundry Patternmaker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Foundry Patternmaker so you can tailor your answers to impress potential employers.

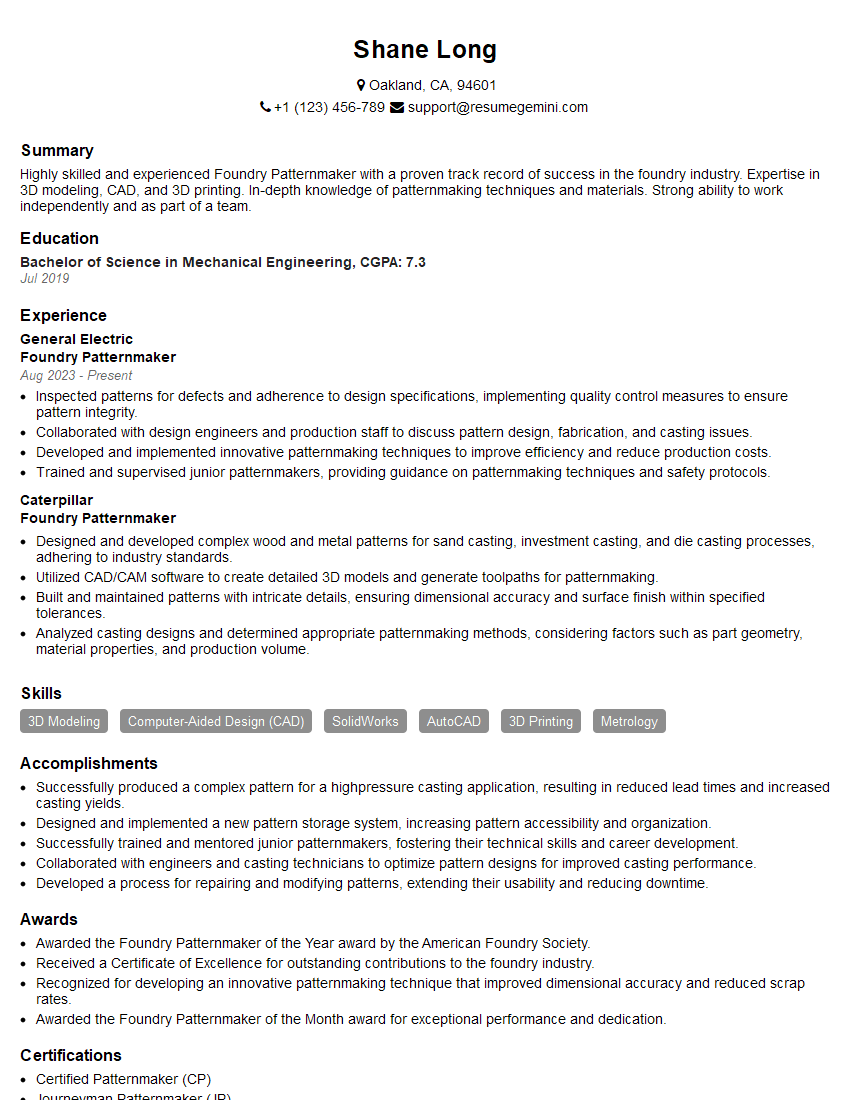

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Patternmaker

1. Explain the different types of patternmaking materials and their uses in the foundry industry?

- Wood: Used for patterns that require intricate details and can be easily carved or shaped.

- Metal: Used for patterns that need to withstand high temperatures and repeated use, such as aluminum or cast iron.

- Plastic: Used for patterns that require complex shapes and can be easily molded, such as ABS or epoxy.

- Foam: Used for patterns that are lightweight and can be easily cut or shaped, such as polystyrene or polyurethane.

2. Describe the process of making a wooden pattern?

Pattern Design

- Study the product drawing.

- Determine the parting line.

- Decide on the type of gating system.

Pattern Making

- Select the appropriate wood.

- Lay out the pattern on the wood.

- Cut and shape the pattern using hand tools or CNC machines.

- Add any necessary features, such as gates, risers, and cores.

3. What are the key factors to consider when designing a gating system for a casting?

- Metal flow rate and fluidity.

- Shape and size of the casting.

- Type of molding process used.

- Desired surface finish.

- Prevention of casting defects.

4. Explain the difference between a cope and a drag in a foundry?

- Cope: The top part of the mold that forms the upper surface of the casting.

- Drag: The bottom part of the mold that forms the lower surface of the casting.

5. What is the purpose of a core in a casting?

- To create internal cavities or shapes within the casting.

- To reduce the amount of metal required.

- To improve the quality of the casting.

6. Describe the steps involved in making a core box?

- Create a model of the core.

- Build a core box around the model.

- Make core prints in the pattern.

- Place the core box in the mold.

- Pour molten metal into the mold.

7. What are the different types of molding processes used in the foundry industry?

- Green sand molding

- Dry sand molding

- Investment casting

- Permanent mold casting

- Die casting

8. Explain the role of a patternmaker in the foundry industry?

- Design and create patterns used to make molds for metal castings.

- Work closely with engineers and foundry personnel to ensure that patterns meet specifications.

- Use a variety of skills and techniques to create patterns, including woodworking, metalworking, and plastic fabrication.

- Stay up-to-date on the latest patternmaking technologies and trends.

9. Describe the different types of pattern allowances and their purposes?

Shrinkage Allowance

- Compensates for the shrinkage of the metal during solidification.

Draft Allowance

- Allows the pattern to be easily removed from the mold.

Machining Allowance

- Provides material for subsequent machining operations.

Shake Allowance

- Compensates for the movement of the pattern during molding.

10. What are some of the common defects that can occur during the casting process and how can they be prevented?

Shrinkage Defects

- Prevention: Use proper gating system, chills, and risers.

Porosity Defects

- Prevention: Use proper molding techniques, degas the metal, and use filters.

Inclusion Defects

- Prevention: Use clean materials, maintain equipment, and train personnel.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Patternmaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Patternmaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foundry Patternmakers craft and maintain patterns, fixtures, and tools essential for the casting processes in a foundry.

1. Pattern Making

Collaborate with engineers to translate designs into physical patterns for casting.

- Utilize various pattern-making techniques including woodworking, metalworking, and molding.

- Select materials and build patterns that meet specific requirements for casting precision.

2. Fixture and Tool Maintenance

Maintain and repair fixtures and tools used in the foundry, including molds, core boxes, and gates.

- Perform routine inspections, identify potential issues, and recommend repairs or replacements.

- Use specialized tools and equipment to keep fixtures and tools in optimal condition.

3. Quality Control

Monitor patterns, fixtures, and tools to ensure adherence to quality standards.

- Inspect patterns and castings to verify dimensional accuracy, surface finish, and other critical criteria.

- Collaborate with quality control personnel to resolve any identified issues and prevent defects.

4. Process Improvement

Continuously evaluate and improve pattern-making practices and processes.

- Identify areas for efficiency improvements, cost reduction, and quality enhancement.

- Implement new techniques, materials, or technologies to optimize pattern-making operations.

Interview Tips and Preparation Guide

Ace your interview by following these comprehensive tips and preparing thoroughly.

1. Research the Foundry Industry

Gain a deep understanding of the foundry industry, including its processes, challenges, and market trends.

- Visit company websites and read industry publications.

- Attend industry events and connect with professionals in the field.

2. Study Pattern-Making Techniques

Master the various pattern-making techniques used in the foundry industry.

- Review textbooks, articles, and online resources on pattern-making.

- Seek hands-on experience through internships or workshops.

3. Practice Your Skills

Develop your practical pattern-making and problem-solving skills.

- Build sample patterns and fixtures to showcase your abilities.

- Solve hypothetical pattern-making challenges presented by potential interviewers.

4. Prepare for Behavioral Questions

Expect behavioral interview questions that assess your work ethic, teamwork skills, and problem-solving abilities.

- Use the STAR method (Situation, Task, Action, Result) to narrate relevant experiences.

- Highlight specific examples that demonstrate your strengths and adaptability.

5. Dress Professionally and Arrive Punctually

Make a positive impression by dressing appropriately and arriving on time for your interview.

- Choose attire that is formal and clean.

- Plan your route in advance to avoid any potential delays.

6. Prepare Questions for the Interviewer

Show your interest and engagement by asking thoughtful questions about the company, the position, and the industry.

- Research the interviewer’s profile to ask personalized questions.

- Inquire about the company’s growth plans and its commitment to innovation.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Foundry Patternmaker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Foundry Patternmaker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.