Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Foundry Process Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

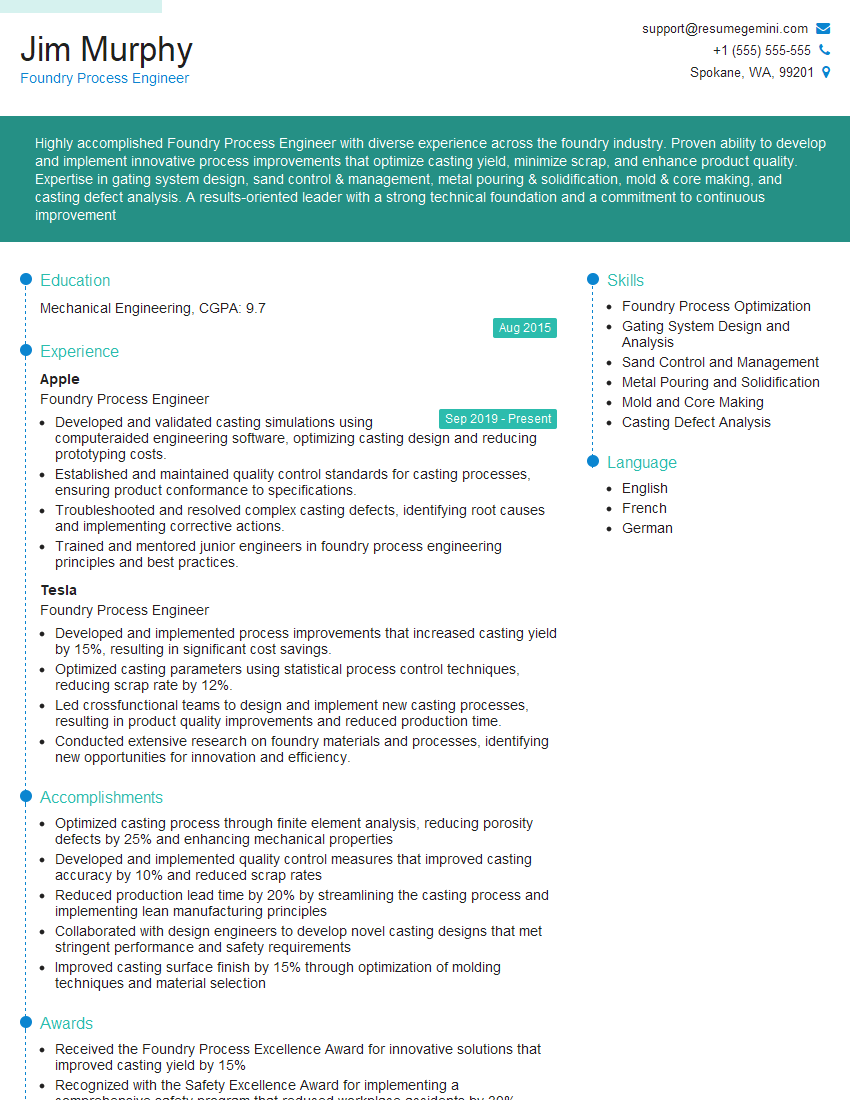

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Process Engineer

1. Explain the steps involved in the casting process?

The casting process involves the following steps:

- Pattern making: Creating a pattern or mold of the desired product.

- Molding: Forming the mold around the pattern.

- Melting: Melting the metal to be poured into the mold.

- Pouring: Pouring the molten metal into the mold.

- Solidification: Allowing the metal to solidify in the mold.

- Removal: Removing the solidified casting from the mold.

- Finishing: Cleaning and finishing the casting to remove any defects.

2. What are the different types of casting processes?

Sand casting

- Uses sand molds to create castings.

- Relatively inexpensive and versatile.

Investment casting

- Uses ceramic shells to create molds.

- Produces high-quality castings with fine details.

- More expensive than sand casting.

Die casting

- Uses metal molds to create castings.

- Produces castings with high precision and repeatability.

- Can be more expensive than other casting methods.

3. What are the factors that affect the quality of castings?

The quality of castings is influenced by various factors, including:

- Mold design: The design of the mold can impact the flow of molten metal and the formation of defects.

- Metal composition: The composition of the molten metal affects its fluidity, strength, and other properties.

- Melting temperature: The temperature at which the metal is melted can affect its properties and the formation of defects.

- Pouring rate: The rate at which the molten metal is poured into the mold can affect the formation of defects.

- Cooling rate: The rate at which the casting cools affects its grain structure and properties.

4. How do you ensure the quality of castings?

Quality assurance in casting involves:

- Inspection: Inspecting castings for defects and dimensional accuracy.

- Testing: Conducting tests to evaluate the mechanical properties and performance of castings.

- Process control: Monitoring and controlling the casting process to ensure consistent quality.

5. Describe the role of gating systems in casting?

Gating systems play a crucial role in:

- Controlling the flow of molten metal into the mold.

- Preventing the formation of defects such as misruns and cold shuts.

- Ensuring the uniform filling of the mold cavity.

6. Explain the principles of solidification in casting?

Solidification in casting is governed by several principles:

- Nucleation: Formation of solid phase nuclei within the molten metal.

- Crystal growth: Growth of solid crystals around the nuclei.

- Dendritic growth: Formation of branched, tree-like crystals.

- Grain structure: Development of grains or crystals within the casting.

7. How do you design a casting process for a given component?

Designing a casting process involves:

- Analyzing the component design and determining its manufacturing requirements.

- Selecting the appropriate casting process based on factors such as material, size, and complexity.

- Designing the mold and gating system to ensure proper metal flow and solidification.

- Establishing process parameters such as melting temperature, pouring rate, and cooling rate.

- Developing quality control procedures to ensure the production of high-quality castings.

8. What are the key challenges in foundry process engineering?

- Producing castings with the desired dimensional accuracy and surface finish.

- Preventing defects such as porosity, shrinkage, and cracks.

- Optimizing the casting process for cost and efficiency.

- Meeting environmental regulations and safety standards.

9. What are the latest trends and advancements in foundry process engineering?

- Additive manufacturing: Utilizing 3D printing techniques to create complex molds and patterns.

- Advanced simulation tools: Employing computer simulations to optimize casting processes and predict defects.

- Automation and robotics: Automating casting operations to improve efficiency and safety.

- Sustainable practices: Implementing green technologies to reduce environmental impact.

10. How do you stay up-to-date with the latest developments in your field?

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in professional organizations.

- Collaborating with colleagues and experts in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Process Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Process Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Foundry Process Engineer plays a crucial role in optimizing foundry operations, ensuring product quality, and improving efficiency.

1. Process Development and Improvement

Develop and implement new or improved foundry processes to enhance productivity, reduce costs, and meet customer requirements.

- Analyze existing processes to identify inefficiencies and areas for optimization.

- Research and evaluate new technologies and materials to improve process efficiency.

2. Quality Control and Assurance

Establish and maintain quality control standards for raw materials, processes, and finished products.

- Monitor and inspect raw materials to ensure they meet specifications.

- Develop and implement testing procedures to ensure product quality meets customer requirements.

3. Equipment and Machinery Management

Manage and maintain foundry equipment and machinery to ensure optimal performance and safety.

- Develop and implement maintenance schedules for equipment to prevent downtime.

- Troubleshoot equipment issues and implement corrective actions to minimize disruptions.

4. Production Planning and Scheduling

Plan and schedule foundry operations to optimize resource utilization and meet production targets.

- Develop production plans to ensure timely delivery of orders.

- Coordinate with other departments to ensure smooth production flow.

Interview Tips

To excel in your Foundry Process Engineer interview, consider the following tips:

1. Research the Company and Industry

Learn about the company’s operations, industry trends, and competitive landscape.

- Visit the company website and review their latest news and announcements.

- Research the latest developments in the foundry industry.

2. Highlight Your Technical Skills

Emphasize your knowledge of foundry processes, quality control techniques, and equipment maintenance.

- Quantify your accomplishments whenever possible, using specific metrics and examples.

- Prepare examples of successful projects where you implemented process improvements or resolved technical challenges.

3. Demonstrate Problem-Solving Abilities

Showcase your skills in identifying and solving problems related to foundry processes and equipment.

- Discuss a time when you identified a problem, analyzed potential causes, and implemented a successful solution.

- Explain your approach to troubleshooting and root cause analysis.

4. Show Your Commitment to Continuous Learning

Express your enthusiasm for staying updated with industry best practices and new technologies.

- Mention any recent courses, workshops, or conferences you have attended.

- Discuss how you stay informed about new developments in the foundry industry through publications or online resources.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Foundry Process Engineer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Foundry Process Engineer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.