Are you gearing up for a career in Foundry Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Foundry Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

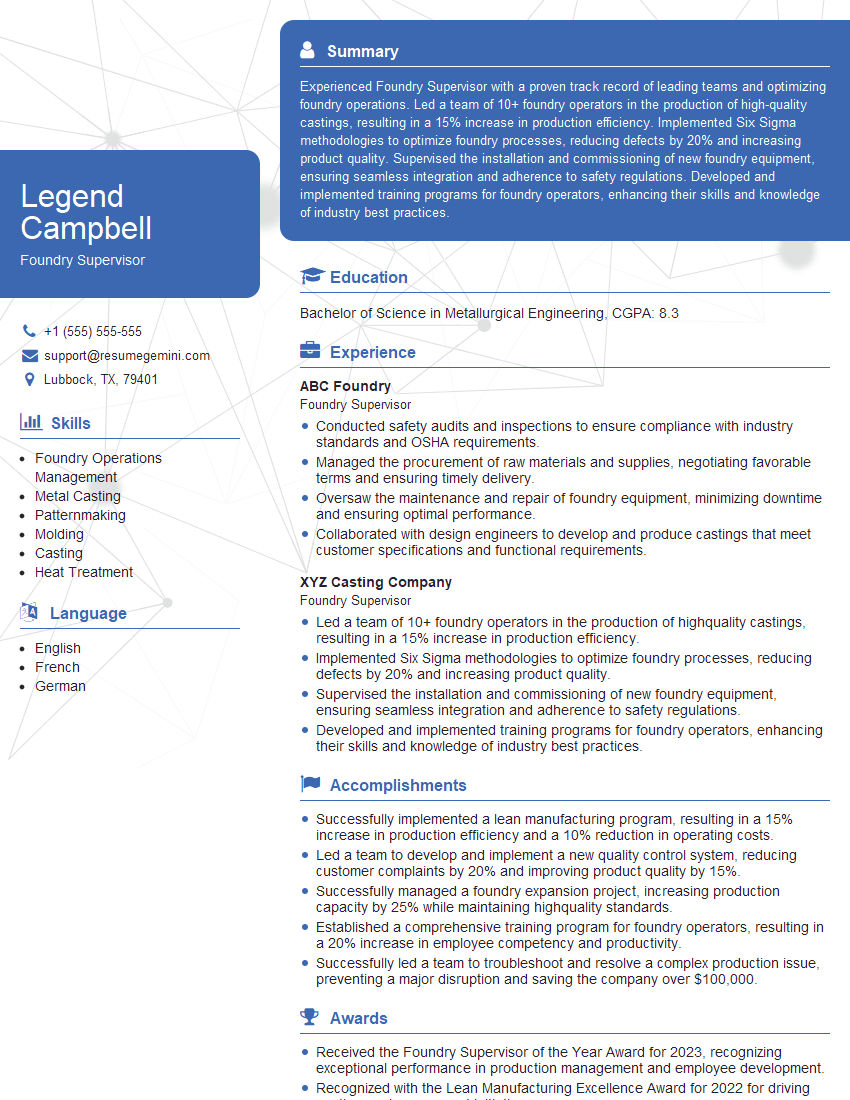

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Supervisor

1. What are the key responsibilities of a Foundry Supervisor?

As a Foundry Supervisor, my core responsibilities include:

- Overseeing all aspects of foundry operations, including production, quality control, and safety

- Managing and motivating a team of foundry workers

- Ensuring compliance with all applicable safety regulations

- Monitoring production schedules and ensuring timely delivery of castings

- Identifying and implementing process improvements to enhance efficiency and quality

2. How do you ensure the quality of castings produced in the foundry?

Quality Control Measures

- Implementing a comprehensive quality control system

- Conducting regular inspections of castings using non-destructive testing methods

- Maintaining proper documentation to track quality data

Process Control

- Ensuring adherence to established process parameters

- Monitoring process variables such as temperature, pressure, and material composition

- Implementing corrective actions based on quality feedback

3. What are the different types of casting defects and how do you prevent them?

Common casting defects include:

- Shrinkage porosity: Caused by inadequate feeding of molten metal during solidification; prevented by modifying mold design and using proper feeding techniques

- Gas porosity: Caused by entrapment of gases during solidification; prevented by degassing the molten metal and using proper gating and venting techniques

- Cold shuts: Caused by premature solidification of molten metal at mold interfaces; prevented by ensuring proper mold preheating and pouring techniques

- Hot tears: Caused by excessive stresses during cooling; prevented by using proper mold design and controlled cooling rates

4. What are the safety hazards associated with foundry operations and how do you mitigate them?

- Molten metal: Burns and splashes; use of protective clothing, face shields, and goggles

- Fumes and gases: Respiratory hazards; use of ventilation systems, respirators, and air monitoring

- Heavy equipment: Injuries; proper training, safe operating procedures, and regular maintenance

- Noise: Hearing loss; use of ear protection and sound dampening measures

5. How do you train and develop your team of foundry workers?

- On-the-job training and mentoring

- Formal training programs on foundry practices and safety protocols

- Regular performance evaluations and feedback

- Encouragement of continuous learning and professional development

6. What are the key metrics used to measure the performance of a foundry?

- Production output and efficiency

- Casting quality and yield

- Safety record and incident rates

- Customer satisfaction and on-time delivery

- Cost-effectiveness and profitability

7. What are the emerging trends and technologies in the foundry industry?

- Additive manufacturing for rapid prototyping and small-batch production

- Advanced simulation software for optimizing foundry processes

- Automated casting equipment and robotics

- Sustainability initiatives and environmentally friendly casting practices

8. How do you stay updated on the latest industry developments?

- Attending industry conferences and workshops

- Reading technical journals and whitepapers

- Participating in professional organizations and networking with peers

- Researching online resources and industry publications

9. What is your approach to troubleshooting and resolving production issues in the foundry?

- Identifying the root cause of the issue

- Evaluating potential solutions and their impact

- Implementing corrective actions and monitoring their effectiveness

- Documenting the issue and resolution for future reference

- Communicating with the team to share lessons learned and prevent recurrence

10. How do you manage a team in a high-pressure environment?

- Setting clear expectations and goals

- Providing regular feedback and support

- Delegating tasks and empowering team members

- Creating a positive and collaborative work environment

- Recognizing and rewarding team achievements

- Addressing conflicts and resolving them in a fair and constructive manner

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Foundry Supervisor is a pivotal role in the foundry industry, holding the responsibility to oversee the entire production process, from planning to execution. Key responsibilities include:

1. Production Management

Directly supervising and managing foundry operations, ensuring adherence to production schedules, quality standards, and safety regulations.

- Scheduling production runs and optimizing resource allocation.

- Monitoring production processes, identifying potential bottlenecks, and implementing improvements.

2. Quality Control

Ensuring that all castings meet the required quality specifications.

- Establishing and maintaining rigorous quality control measures.

- Conducting regular inspections and audits.

- Working closely with the quality assurance team to identify and resolve quality issues.

3. Safety Management

Enforcing strict safety protocols and ensuring a safe working environment.

- Developing and implementing comprehensive safety policies.

- Providing safety training and education to employees.

- Monitoring safety performance and conducting regular audits.

4. Team Leadership

Leading and managing a team of foundry operators, technicians, and other staff.

- Developing and motivating the team to achieve optimal performance.

- Providing performance evaluations and professional development opportunities.

- Maintaining open communication and resolving conflicts effectively.

Interview Tips

To ace the interview for a Foundry Supervisor role, candidates can follow these preparation tips and hacks:

1. Research the Company and Industry

Thoroughly research the company’s profile, industry trends, and the specific foundry operation’s processes. This will enable you to tailor your answers and demonstrate your understanding of the role.

- Visit the company’s website, read industry publications, and connect with current or former employees.

- If possible, learn about the specific foundry’s production processes and areas of specialization.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in the foundry industry, including knowledge of various casting processes, quality control techniques, and safety procedures. Highlight any experience in production management, team leadership, and problem-solving.

- Quantify your accomplishments and provide specific examples of your contributions in previous roles.

- If you have experience with specific foundry software or equipment, highlight your proficiency.

3. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that showcase your qualifications and enthusiasm for the role. Some likely questions include:

- Tell me about your experience in foundry operations.

- How would you ensure the quality of castings?

- Describe your approach to safety management in a foundry environment.

- How would you motivate and lead a team of foundry operators?

4. Ask Insightful Questions

During the interview, actively ask questions to demonstrate your engagement and interest in the company and role. This also allows you to gain valuable information about the foundry’s operations and culture.

- Inquire about the company’s expansion plans or future technology investments.

- Ask about the current challenges and opportunities in the foundry industry.

5. Be Confident and Professional

Maintain a positive and confident attitude throughout the interview. Dress professionally, make eye contact, and speak clearly and concisely. Show enthusiasm for the role and the opportunity to contribute to the foundry’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Foundry Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!