Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Foundry Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

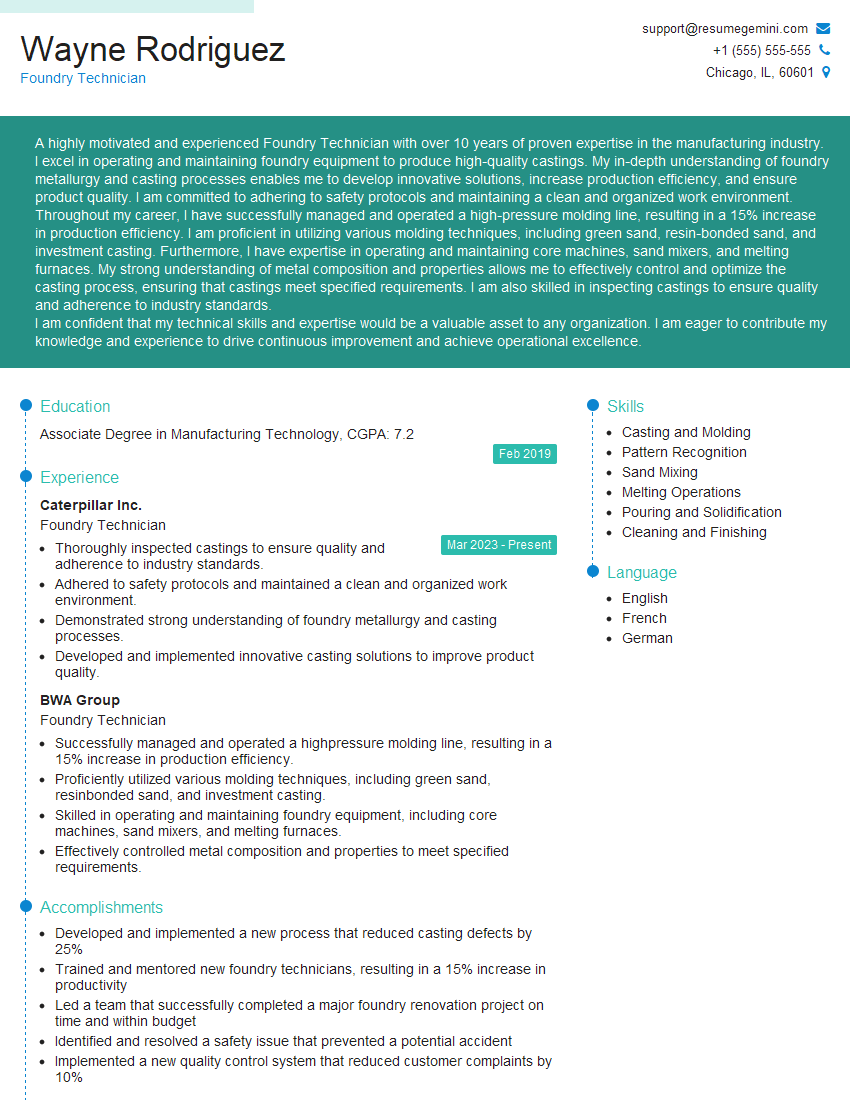

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Technician

1. What is the purpose of a sand binder in a foundry process?

The purpose of a sand binder in a foundry process is to hold the sand particles together to form a mold or core. It provides strength and cohesion to the sand mixture, allowing it to withstand the forces of molten metal during casting.

2. Describe the steps involved in the investment casting process.

Wax pattern creation

- A wax pattern is created using a master pattern or a 3D printed model.

Investment mold creation

- The wax pattern is coated with a series of ceramic slurries.

- The coated pattern is placed in a flask and filled with molten ceramic investment.

- The investment is allowed to solidify, forming a hard mold around the wax pattern.

Wax removal

- The wax pattern is melted and drained out of the investment mold.

Casting

- Molten metal is poured into the investment mold, filling the cavity left by the wax pattern.

Investment removal

- After the metal has solidified, the investment is broken away to reveal the finished casting.

3. What are the different types of core boxes used in the foundry industry?

- Single-piece core boxes: Used for simple cores that do not require parting lines.

- Split core boxes: Used for more complex cores that require parting lines. The box is split into two or more pieces to allow for easy removal of the core.

- Collapsible core boxes: Used for cores that need to be removed from the casting after solidification. The box is designed to collapse after the core has been hardened, making it easier to remove.

4. What is the importance of gating and risering in the foundry process?

- Gating: Controls the flow of molten metal into the mold cavity.

- Risering: Provides a reservoir of molten metal to compensate for shrinkage during solidification and minimize defects.

5. What are the common defects found in castings?

- Shrinkage porosity

- Gas porosity

- Cracks

- Cold shuts

- Misruns

6. How do you ensure the quality of castings?

- Proper mold design

- Control of materials (metal, sand binders, etc.)

- Proper melting and pouring practices

- Non-destructive testing (NDT)

7. What is the difference between a green sand mold and a dry sand mold?

- Green sand mold: Made from moist sand that contains clay as a binder.

- Dry sand mold: Made from sand that has been dried and mixed with a binder, such as resin or phenolic.

8. What are the advantages and disadvantages of using a centrifugal casting process?

Advantages:

- Improved mechanical properties

- Reduced defects

- Increased production rate

Disadvantages:

- Limited to certain shapes

- Higher equipment costs

9. How do you control the grain structure of a casting?

- Cooling rate

- Alloy composition

- Mold design

10. What are the safety precautions that must be taken when working in a foundry?

- Wear proper protective clothing (gloves, apron, safety glasses, etc.)

- Be aware of molten metal hazards

- Ventilate properly to minimize exposure to fumes and gases

- Follow established safety protocols

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foundry Technicians are responsible for a wide range of tasks in a foundry, including:

1. Molding

Preparing and pouring molds for casting metal objects.

- Assembling and operating molding machines.

- Inspecting molds for defects.

2. Casting

Melting and pouring molten metal into molds to cast metal objects.

- Operating furnaces and other casting equipment.

- Inspecting castings for defects.

3. Finishing

Removing excess metal and other materials from castings, and preparing them for use.

- Cutting and grinding castings.

- Testing and inspecting castings.

4. Maintenance

Maintaining and repairing machinery and equipment in the foundry.

- Troubleshooting and fixing mechanical problems.

- Performing routine maintenance checks.

Interview Tips

To ace your foundry technician interview, you should prepare by practicing your answers to common interview questions.

1. Tell me about yourself.

Start with a brief overview of your work history and education. Then, focus on your skills and experience that are relevant to the job. For example, you could mention your experience in molding, casting, finishing, or maintenance.

- Example: “I have been working as a foundry technician for the past 5 years. In my previous role, I was responsible for all aspects of the casting process, from preparing the molds to inspecting the finished castings.”

- Example: “I have a strong background in metalworking and manufacturing. I have worked in a foundry setting for the past 3 years, and I am proficient in all aspects of the casting process.”

2. Why are you interested in this job?

In your answer, be sure to highlight your interest in the foundry industry and your desire to work for the specific company. You should also mention any specific skills or experience that make you a good fit for the job.

- Example: “I am interested in this job because I am passionate about the foundry industry. I have always been fascinated by the process of metal casting, and I am eager to learn more about it.”

- Example: “I am interested in this job because I believe that my skills and experience make me a good fit for the position. I have a strong background in molding, casting, and finishing, and I am confident that I can make a significant contribution to your company.”

3. What are your strengths and weaknesses?

When answering this question, be honest about your strengths and weaknesses. However, focus on your strengths and how they will benefit the company.

- Example: “My strengths include my attention to detail, my ability to work independently, and my teamwork skills. I am also a quick learner and I am eager to take on new challenges.”

- Example: “One of my weaknesses is that I can be impatient at times. However, I am working on improving my patience and I am confident that I will be able to overcome this weakness.”

4. What are your salary expectations?

When answering this question, it is important to research the average salary for foundry technicians in your area. You should also consider your own experience and skills.

- Example: “My salary expectations are in line with the average salary for foundry technicians in my area. I am also confident that my experience and skills make me a valuable asset to your company.”

- Example: “I am open to negotiating my salary based on the responsibilities of the position and the company’s budget.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Foundry Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.