Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fountain Pen Nibs Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fountain Pen Nibs Inspector so you can tailor your answers to impress potential employers.

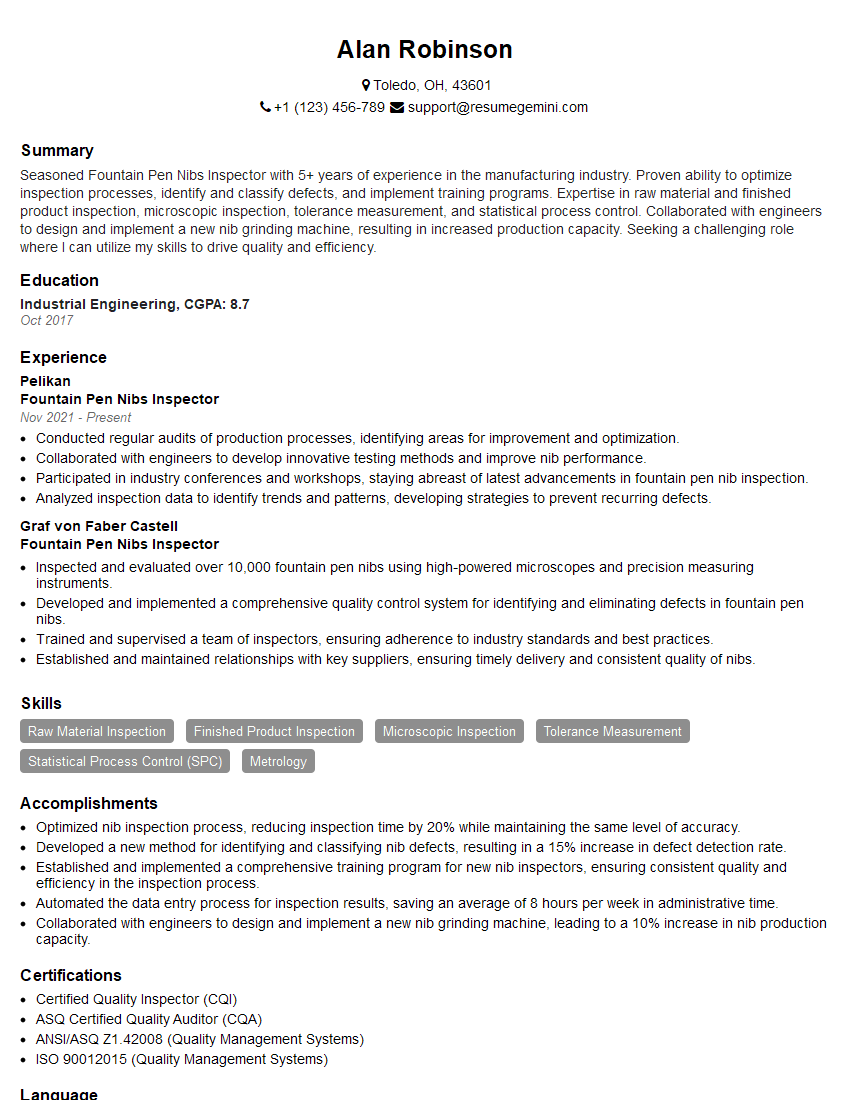

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fountain Pen Nibs Inspector

1. What are the key quality attributes you inspect in a fountain pen nib?

As a Fountain Pen Nibs Inspector, I meticulously evaluate various quality attributes to ensure the nib meets the highest standards. These attributes include:

- Slit width and alignment: Verifying that the slit between the nib’s tines is precise and centered for optimal ink flow.

- Iridium tipping: Inspecting the iridium tip for proper shape, size, and alignment, as it directly affects the pen’s writing performance.

- Tine flexibility and elasticity: Assessing the flexibility of the nib’s tines to provide a responsive writing experience.

- Ink flow and smoothness: Testing the nib’s ability to deliver a smooth and consistent ink flow, ensuring an enjoyable writing experience.

- Overall finish and aesthetics: Verifying that the nib is free from any scratches, burrs, or blemishes that may affect its appearance or function.

2. Describe the process you follow to inspect and grade fountain pen nibs.

Visual Inspection:

- Examining the nib under magnification to check for any visible defects, such as scratches, burrs, or misalignment.

- Assessing the nib’s overall shape, size, and finish to ensure it meets specifications.

Functional Testing:

- Testing the nib’s ink flow by dipping it into ink and observing the smoothness and consistency of the ink delivery.

- Evaluating the nib’s writing performance by writing with it on different types of paper to assess its smoothness, flexibility, and responsiveness.

Grading:

- Based on the results of the inspection and testing, assigning a grade to the nib that reflects its quality and performance.

- Documenting the inspection findings and grading for future reference and traceability.

3. What equipment and tools do you use in your daily inspection tasks?

- Magnifying glass or microscope: For detailed visual inspection of the nib’s surface and structure.

- Ink testing station: To assess the nib’s ink flow and consistency.

- Writing samples: Different types of paper to test the nib’s writing performance under various conditions.

- Inspection checklist: A standardized list of quality attributes to guide the inspection process.

- Grading scale: A predefined system for assigning grades to the nibs based on their quality.

4. How do you handle and store fountain pen nibs to ensure their quality and prevent damage?

- Proper handling: Using clean and soft tools to avoid scratching or bending the nib.

- Humidity and temperature control: Storing nibs in a controlled environment with proper humidity and temperature to prevent corrosion or warping.

- Anti-static precautions: Taking measures to prevent electrostatic discharge that could damage the nib’s delicate structure.

- Appropriate packaging: Using specialized packaging materials to protect the nibs from physical damage during storage or transportation.

- Regular cleaning: Cleaning nibs periodically to remove ink residue or contaminants that could affect their performance.

5. What are the common defects you encounter in fountain pen nibs and how do you address them?

- Misaligned tines: Adjusting the tines using specialized tools to ensure proper alignment for optimal ink flow.

- Uneven iridium tipping: Re-tipping the nib with precision equipment to create a smooth and symmetrical surface.

- Scratches or burrs: Polishing or smoothing the nib’s surface to remove imperfections and ensure a smooth writing experience.

- Poor ink flow: Inspecting the nib’s feed system and making necessary adjustments to improve ink delivery.

- Tine flexibility issues: Assessing the nib’s elasticity and adjusting the tension as needed to provide the desired writing characteristics.

6. How do you stay up-to-date with the latest industry standards and best practices for fountain pen nib inspection?

- Attending industry conferences and workshops: Participating in events to learn about new techniques and advancements in nib inspection.

- Reading technical publications and research papers: Keeping up with industry literature to stay informed about the latest research and developments.

- Collaborating with other nib inspectors: Exchanging knowledge and experiences with colleagues to share best practices and improve inspection techniques.

- Seeking training and certification: Pursuing industry-recognized certifications to demonstrate expertise and stay abreast of best practices.

- Customer feedback analysis: Monitoring customer feedback and reviews to identify areas for improvement in nib inspection and quality control.

7. How do you manage the workload and prioritize tasks when inspecting large quantities of fountain pen nibs?

- Prioritization: Establishing clear priorities for nib inspection based on factors such as urgency, customer requirements, and quality standards.

- Efficient workflow: Optimizing the inspection process to maximize efficiency and reduce bottlenecks.

- Team collaboration: Working effectively with other inspectors to distribute workload and ensure timely completion of tasks.

- Time management: Utilizing time management techniques to stay organized and meet deadlines without compromising quality.

- Flexibility and adaptability: Adjusting the inspection schedule and workload as needed to accommodate unforeseen circumstances or changes in priorities.

8. How do you ensure the accuracy and consistency of your fountain pen nib inspections?

- Standardized inspection procedures: Following established inspection protocols to ensure uniformity and minimize subjectivity.

- Calibration and maintenance of equipment: Regularly calibrating and maintaining inspection equipment to ensure accurate and reliable measurements.

- Peer review and cross-checking: Having inspections reviewed by a second inspector to verify accuracy and reduce the risk of errors.

- Quality control measures: Implementing statistical quality control techniques to monitor the inspection process and identify areas for improvement.

- Continuous improvement: Regularly evaluating and improving inspection techniques to enhance accuracy and consistency.

9. What are the ethical considerations and responsibilities of a Fountain Pen Nibs Inspector?

- Objectivity and impartiality: Conducting inspections with fairness and without bias, ensuring accurate and unbiased assessments.

- Confidentiality: Maintaining the confidentiality of customer information and sensitive inspection data.

- Integrity and honesty: Reporting inspection results truthfully and accurately, even if they are unfavorable.

- Continuous learning and development: Staying up-to-date with industry best practices and advancements to enhance professional competence.

- Adherence to industry standards: Complying with established industry standards and regulations to ensure the quality and accuracy of inspections.

10. How do you handle situations where you encounter nibs that do not meet the quality standards?

- Thorough evaluation: Re-inspecting the nib to confirm the defect and determine its severity.

- Documentation and reporting: Documenting the defect and reporting it to the appropriate personnel for further investigation and corrective action.

- Communication with customers: Informing customers about the defect and providing them with options for repair or replacement.

- Collaboration with manufacturing team: Working with the manufacturing team to identify the root cause of the defect and implement measures to prevent its recurrence.

- Continuous improvement: Using the feedback from defective nibs to enhance inspection techniques and improve quality control processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fountain Pen Nibs Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fountain Pen Nibs Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fountain Pen Nibs Inspector is responsible for checking the quality and accuracy of fountain pen nibs before they are assembled into pens. This role requires precision, attention to detail, and an understanding of the fountain pen manufacturing process. Key responsibilities include:

1. Inspecting Nibs for Defects

Inspecting nibs for defects such as cracks, burrs, or misalignment under magnification.

- Using specialized gauges to measure nib dimensions and tolerances.

- Ensuring nibs meet specifications for smoothness, flow rate, and writing quality.

2. Testing Nib Performance

Testing nib performance by dipping them in ink and writing on various surfaces.

- Assessing nibs for smoothness, ink flow, and skip rate.

- Identifying and correcting any issues that affect nib performance.

3. Maintaining Inspection Equipment

Maintaining and calibrating inspection equipment such as gauges, microscopes, and writing surfaces.

- Following established maintenance schedules to ensure accuracy and consistency.

- Reporting any equipment malfunctions or maintenance needs.

4. Collaborating with Production Team

Collaborating with the production team to identify and resolve quality issues.

- Providing feedback on nib quality and performance.

- Working with engineers to improve nib design and manufacturing processes.

Interview Tips

To ace the Fountain Pen Nibs Inspector interview, candidates should prepare thoroughly and demonstrate their skills and knowledge. Here are some interview tips:

1. Research the Company and Role

Research the company’s history, values, and products. Familiarize yourself with the specific role and responsibilities of a Fountain Pen Nibs Inspector.

- Use the company website, LinkedIn, and other online resources to gather information.

- Read industry publications and articles to stay updated on the latest trends and technologies.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in quality control, inspection, and precision measurement. Highlight any experience with fountain pens or other writing instruments.

- Quantify your accomplishments and provide specific examples of your work.

- Use action verbs to describe your skills and abilities, such as “inspected,” “tested,” “calibrated,” and “collaborated.”

3. Prepare for Technical Questions

Be prepared for technical questions about fountain pen nibs, inspection techniques, and quality control standards. Practice answering questions using your knowledge and experience.

- Review basic concepts of fountain pen nibs, such as materials, shapes, and sizes.

- Explain the different types of defects that can be found in nibs and how to identify them.

4. Ask Insightful Questions

Asking thoughtful questions during the interview shows that you are engaged and interested in the position. Prepare questions related to the company, the role, and the industry.

- Ask about the company’s quality control processes and how they ensure product quality.

- Inquire about the company’s commitment to innovation and product development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fountain Pen Nibs Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.