Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Four Corner Stayer Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

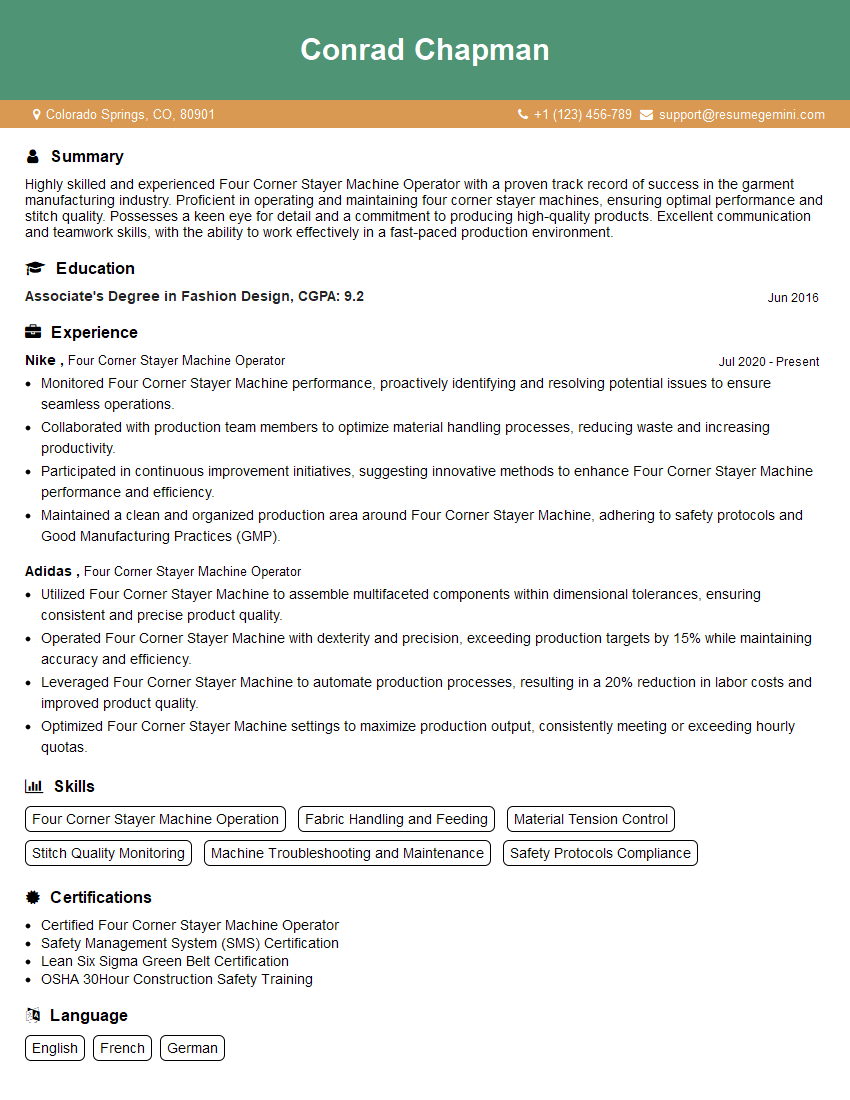

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Four Corner Stayer Machine Operator

1. Explain the process of setting up a four corner stayer machine for a new job?

The process of setting up a four corner stayer machine for a new job involves several steps:

- Load the paper stack into the machine’s feeder.

- Adjust the machine’s settings to match the job specifications, including the paper size, type, and number of stitches.

- Thread the machine with the correct thread and tension settings.

- Position the paper guides to ensure the paper is fed into the machine correctly.

- Calibrate the machine’s stitching head to ensure the stitches are properly formed and spaced.

- Run a few test stitches to verify the machine is set up correctly.

2. How do you troubleshoot a four corner stayer machine that is producing jams?

Identifying the Cause of the Jam

- Check the paper path for any obstructions or debris.

- Inspect the stitching head for any damaged or worn components.

- Verify that the thread is properly tensioned and not tangled.

Resolving the Jam

- Clear any obstructions or debris from the paper path.

- Replace any damaged or worn components in the stitching head.

- Adjust the thread tension settings as necessary.

- Retread the machine with new thread.

3. Describe the maintenance procedures required for a four corner stayer machine?

Regular maintenance is crucial for the proper functioning and longevity of a four corner stayer machine. Essential maintenance procedures include:

- Daily: Cleaning the machine’s exterior, paper path, and stitching head.

- Weekly: Oiling and lubricating moving parts.

- Monthly: Checking and adjusting the machine’s settings.

- Quarterly: Inspecting and replacing worn or damaged components.

- Annually: Having the machine serviced by a qualified technician.

4. How do you ensure the quality of the stitched products produced by a four corner stayer machine?

To ensure high-quality stitched products, it is essential to:

- Properly set up the machine according to job specifications.

- Use high-quality paper and thread.

- Monitor the machine’s performance during operation.

- Inspect the stitched products regularly for any defects.

- Take corrective actions promptly to address any quality issues.

5. What safety precautions should be taken when operating a four corner stayer machine?

Operating a four corner stayer machine requires adherence to strict safety precautions:

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep hands away from moving parts.

- Do not attempt to clear jams while the machine is running.

- Disconnect the machine from power before performing any maintenance or repairs.

- Follow all manufacturer’s instructions and safety guidelines.

6. Describe the different types of stitching patterns that can be produced on a four corner stayer machine?

Four corner stayer machines offer a range of stitching patterns to meet various binding requirements:

- Saddle stitch: Two staples placed parallel to the spine.

- Loop stitch: A continuous loop of thread that wraps around the spine.

- Side stitch: Staples placed along one side of the spine.

- Corner stitch: Staples placed at each corner of the document.

- Custom stitch: Patterns created to meet specific binding needs.

7. How do you adjust the stitching depth on a four corner stayer machine?

Adjusting the stitching depth ensures the staples penetrate the paper adequately without causing damage. To adjust the depth:

- Locate the depth adjustment screw on the machine.

- Use a screwdriver to turn the screw clockwise to increase the depth or counterclockwise to decrease it.

- Run a few test stitches to verify the desired depth.

8. What factors influence the choice of thread for use in a four corner stayer machine?

Selecting the appropriate thread is crucial for optimal stitching quality. Factors to consider include:

- Paper type and thickness

- Stitching pattern

- Desired strength and durability

- Thread diameter and tension

- Environmental conditions

9. How do you handle and store paper to prevent jams and ensure smooth operation of a four corner stayer machine?

Proper paper handling and storage are essential for jam-free operation:

- Store paper in a dry, climate-controlled environment.

- Avoid storing paper near heat sources.

- Keep paper stacks neat and aligned.

- Load paper into the machine’s feeder gently, avoiding bending or creasing.

- Monitor the paper supply during operation to prevent running out.

10. Describe your experience in troubleshooting and repairing four corner stayer machines?

Troubleshooting

- Identify the problem by observing the machine’s behavior and error messages.

- Consult the manufacturer’s manual for possible solutions.

- Check for loose connections, damaged parts, or incorrect settings.

Repairing

- Disconnect the machine from power.

- Replace damaged components as necessary.

- Adjust or calibrate settings according to the manufacturer’s specifications.

- Test the repaired machine to ensure proper functionality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Four Corner Stayer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Four Corner Stayer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Four Corner Stayer Machine Operator is responsible for operating a four corner stayer machine to bind materials together. The primary duties include:

1. Machine Operation

Operate a four corner stayer machine to stitch and bind materials

- Set up and adjust the machine according to job specifications.

- Load materials into the machine and ensure they are properly aligned and fed through the stitching process.

2. Quality Control

Inspect the finished products to ensure they meet quality standards

- Check for proper stitching, alignment, and overall finish.

- Identify and correct any defects or errors.

3. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting on the four corner stayer machine

- Clean and lubricate the machine regularly.

- Identify and resolve minor mechanical issues.

4. Production Monitoring

Monitor production output and maintain efficiency

- Track production rates and identify areas for improvement.

- Report any production issues or delays to supervisors.

Interview Tips

To prepare for an interview for a Four Corner Stayer Machine Operator position, candidates should consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s website, mission, and values to demonstrate your interest and knowledge.

- Review the job description thoroughly to understand the specific requirements and expectations.

- Research the industry and market trends to show your awareness and enthusiasm for the field.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in operating four corner stayer machines or similar equipment.

- Quantify your accomplishments whenever possible, providing specific examples of your productivity and efficiency.

- Describe your knowledge of quality control processes and your ability to identify and correct defects.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers and providing thoughtful examples.

- Tell me about your experience operating a four corner stayer machine.

- Describe your quality control process and how you ensure the accuracy of your work.

4. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving for the interview on time.

- Be punctual and show respect for the interviewers’ time.

- Dress appropriately for the industry and company culture.

5. Ask Insightful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement.

- Inquire about the company’s training and development opportunities.

- Ask about the company’s commitment to quality and customer satisfaction.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Four Corner Stayer Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Four Corner Stayer Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.