Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fourdrinier Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

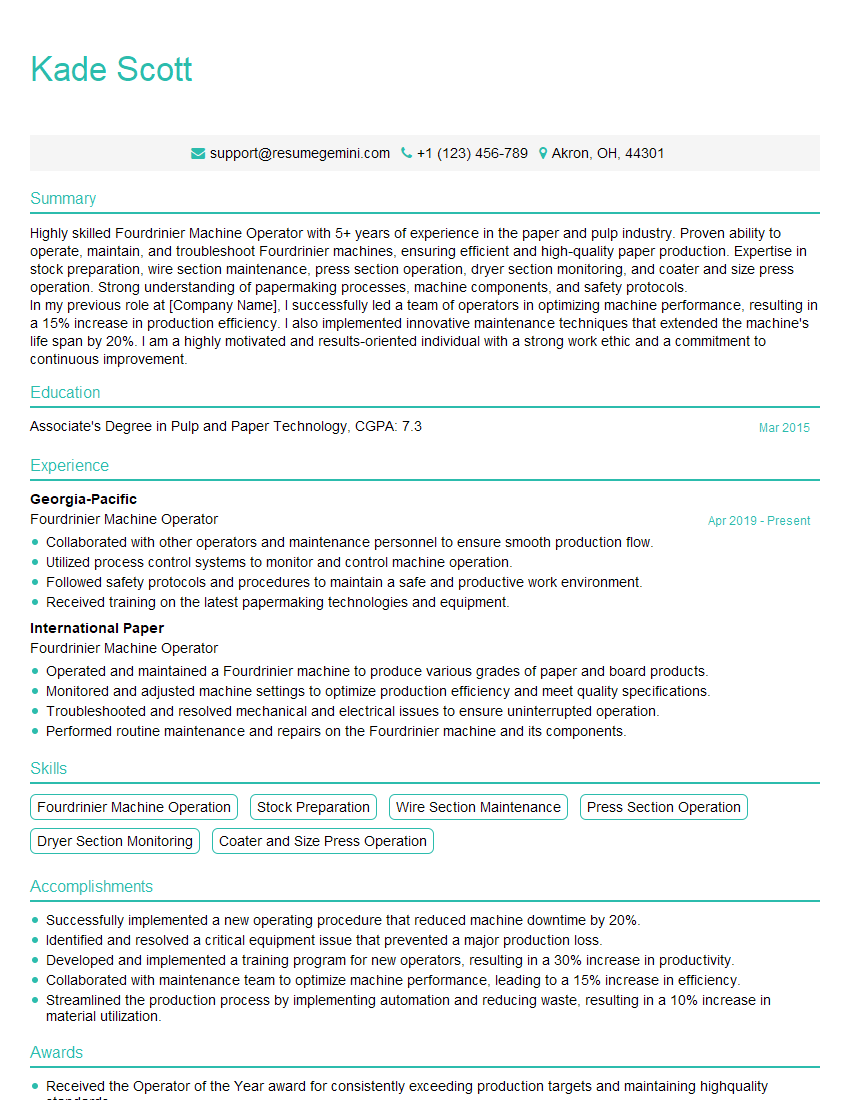

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fourdrinier Machine Operator

1. What are the key components of a Fourdrinier machine?

The key components of a Fourdrinier machine include:

- Headbox: Distributes the paper pulp slurry evenly onto the wire mesh.

- Wire mesh: Conveys the paper web through the forming section.

- Press section: Removes water from the paper web using pressure rollers.

- Drying section: Evaporates remaining water from the paper web using heated rollers.

- Calendering section: Smoothen and compact the surface of the paper.

2. How do you control the consistency of the paper pulp slurry?

Factors to consider

- Pulp concentration: Adjust the ratio of fibers to water.

- Viscosity: Control the flow properties of the slurry using additives.

- Temperature: Maintain the slurry temperature within an optimal range.

Monitoring and adjustment

- Use consistency meters to monitor pulp concentration.

- Adjust flow rates and add chemicals to control viscosity.

- Regulate heating systems to maintain desired temperature.

3. What are the common defects in paper products and how do you rectify them?

Common defects and their rectifications:

- Holes: Caused by entrapped air or debris. Rectify by optimizing headbox flow and removing impurities.

- Wrinkles: Result from uneven tension or moisture. Adjust tension rollers and improve moisture control.

- Thickness variations: Caused by inconsistent pulp distribution or press section problems. Optimize headbox delivery and adjust press settings.

- Spots: Caused by contaminants in the pulp. Implement effective filtration and cleaning procedures.

4. Describe the role of the Fourdrinier wire in the papermaking process.

- Supports the paper web: The wire provides a foundation for the formation of the paper sheet.

- Drains water: The wire’s mesh allows water to pass through, dewatering the paper web.

- Conveys the paper web: The wire carries the paper web through the forming, press, and drying sections.

5. How do you maintain and clean the Fourdrinier machine?

Maintenance and cleaning include:

- Regular cleaning: Remove debris from the wire, press rollers, and other components to prevent buildup.

- Lubrication: Apply lubricants to moving parts to reduce friction and wear.

- Inspections: Conduct periodic inspections to identify potential problems and address them promptly.

6. What is the importance of maintaining proper temperature in the drying section?

Maintaining proper temperature in the drying section is crucial for:

- Drying efficiency: Adequate temperature ensures efficient evaporation of water, reducing drying time.

- Paper properties: Controlled temperature prevents damage to the paper’s physical and mechanical properties.

7. How do you handle and resolve production issues on the Fourdrinier machine?

Steps for handling production issues:

- Identify the issue: Quickly assess the situation and determine the root cause.

- Implement solutions: Based on the identified cause, apply appropriate corrective actions to resolve the issue.

- Monitor and adjust: Continuously monitor the situation and make necessary adjustments to maintain optimal machine performance and minimize downtime.

8. What is the role of the press section in the papermaking process?

The press section:

- Further dewaters the paper web: Removes a significant amount of water by applying pressure through rollers.

- Compacts the paper web: Pressure helps bond the paper fibers, increasing the strength and density of the paper.

- Prepares the paper web: Creates a more suitable surface for subsequent drying and finishing processes.

9. Describe the safety precautions you take while operating a Fourdrinier machine.

- Wear appropriate PPE: Safety glasses, gloves, and protective clothing to minimize exposure to hazards.

- Follow safety protocols: Adhere to established safety procedures for machine operation and maintenance.

- Be aware of surroundings: Pay attention to moving parts, hot surfaces, and potential hazards in the work area.

10. How do you optimize the efficiency of a Fourdrinier machine?

Optimizing efficiency involves:

- Regular maintenance: Preventive maintenance reduces downtime and ensures peak performance.

- Process control: Monitor and adjust machine parameters, such as speed and temperature, to maximize production.

- Training operators: Well-trained operators can operate the machine effectively and identify potential issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fourdrinier Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fourdrinier Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Fourdrinier Machine Operator’s role is crucial in the manufacturing of paper, requiring a comprehensive understanding of the machine and its various components. Their primary responsibilities include:

1. Machine Operation

Skilfully run the Fourdrinier machine, ensuring optimal production and paper quality.

- Monitor machine settings, controlling sheet formation, weight, and moisture content.

- Identify and rectify any operational issues promptly, minimizing production downtime.

2. Quality Control

Uphold stringent quality standards by monitoring and testing paper properties.

- Conduct routine tests to ensure paper meets specifications for weight, thickness, and strength.

- Collaborate with quality control personnel to identify and resolve quality problems.

3. Maintenance and Repair

Contribute to preventative maintenance and repair activities to ensure machine reliability.

- Carry out regular inspections and lubrications to minimize wear and tear.

- Troubleshoot and repair minor issues, coordinating with maintenance technicians for complex repairs.

4. Safety and Environment

Adhere to all safety regulations and environmental protocols to protect personnel and the environment.

- Operate the machine in a safe and responsible manner, following established safety procedures.

- Monitor environmental emissions and implement measures to comply with regulations.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of impressing the interviewer and securing the job. Here are some effective tips to help you ace the interview for a Fourdrinier Machine Operator position:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific requirements of the job. This demonstrates your interest and enthusiasm for the role.

- Visit the company’s website to gather information about their products, services, and operations.

- Review the job description carefully, noting the key responsibilities and qualifications required.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivations. Rehearse your answers to articulate your strengths and abilities effectively.

- Examples of common interview questions include “Tell me about your experience operating Fourdrinier machines” and “How do you maintain quality standards in paper manufacturing?”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples to support your claims.

3. Highlight Your Technical Skills and Knowledge

Emphasize your technical proficiency and in-depth understanding of Fourdrinier machines. Showcase your ability to monitor, control, and troubleshoot the machine’s operations.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your work.

- Discuss your experience with specific aspects of the machine, such as headbox design, wire section, and press section.

4. Demonstrate Your Problem-Solving Abilities

Highlight your ability to identify and resolve issues that arise during production. Provide examples of how you have used critical thinking and problem-solving skills to optimize machine performance.

- Describe a situation where you encountered a production problem and explain the steps you took to diagnose and resolve it.

- Emphasize your ability to work independently and as part of a team to achieve results.

5. Be Professional and Enthusiastic

Dress appropriately and arrive on time for your interview. Maintain a confident and positive demeanor throughout the process. Show enthusiasm for the papermaking industry and express your eagerness to contribute to the team.

- Make eye contact, speak clearly, and actively listen to the interviewer’s questions.

- Ask thoughtful questions at the end of the interview to demonstrate your engagement and interest in the role.

Next Step:

Now that you’re armed with the knowledge of Fourdrinier Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Fourdrinier Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini