Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fourdrinier Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

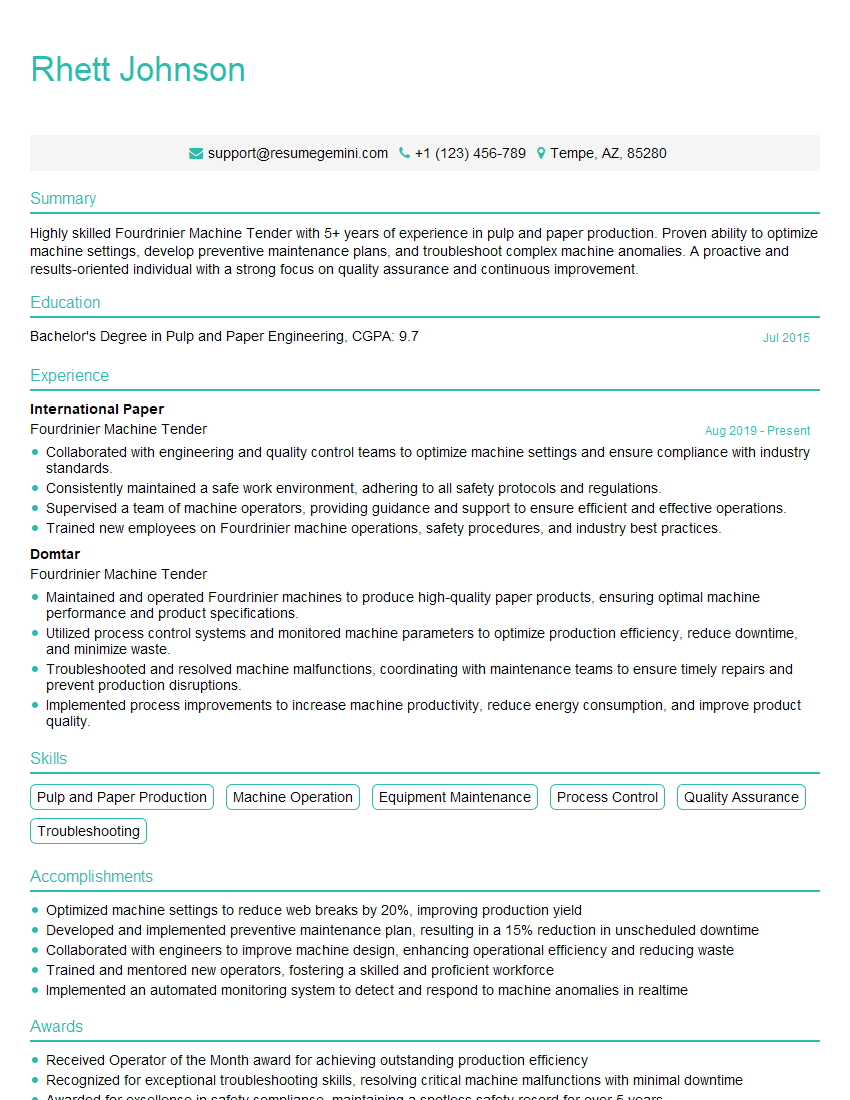

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fourdrinier Machine Tender

1. Describe the role and functions of the headbox in the Fourdrinier machines?

The headbox plays a significant role in the Fourdrinier papermaking process. Its primary functions include:

- Providing a uniform suspension of fibers and other additives to form the paper web.

- Controlling the consistency and flow rate of the stock to ensure a steady supply for the wire section.

- Removing any unwanted contaminants or foreign objects that could damage the paper or machinery.

- Adjusting the stock properties, such as pH and temperature, to optimize papermaking conditions.

- Maintaining a stable headbox pressure to minimize fluctuations in sheet formation.

2. What are the critical parameters to monitor and control in the press section of a Fourdrinier machine?

Press Felt Moisture

- Optimizing press felt moisture is crucial for removing water efficiently and avoiding felt blinding.

- Excessive moisture can weaken the felt, while insufficient moisture can reduce dewatering and increase energy consumption.

Press Roll Pressure

- Proper press roll pressure helps consolidate the paper web, reduce moisture content, and improve sheet strength.

- Excessive pressure can crush the fibers, while insufficient pressure can result in poor dewatering and low sheet density.

Draw Control

- Maintaining the correct draw between the press sections is essential for avoiding web breaks and ensuring proper sheet formation.

- Excessive draw can stretch the web, while insufficient draw can cause wrinkles and web breaks.

3. Explain the purpose and operation of the dryer section in a Fourdrinier machine?

The dryer section performs a critical role in removing moisture from the paper web and completing the papermaking process. Here’s how it operates:

- The wet paper web, containing up to 70% moisture, enters the dryer section.

- The web passes through a series of heated drying cylinders, typically arranged in multiple tiers.

- Hot air is circulated through the cylinders, transferring heat to the paper web and evaporating moisture.

- As the web travels through the dryers, its moisture content gradually decreases until it reaches the desired level, typically around 5-8%.

- The dried paper web is then wound onto reels for further processing or storage.

4. Describe the principles of operation of a calender stack?

A calender stack is a series of rolls arranged in a vertical stack that imparts a smooth, glossy finish to the paper web. Here’s how it works:

- The paper web passes between a series of rolls, alternating between hard and soft.

- The hard rolls apply pressure, while the soft rolls conform to the surface of the paper.

- The combination of pressure and heat from the rolls compresses the paper fibers, resulting in a smoother and more uniform surface.

- Calendering can also be used to adjust the gloss, opacity, and other properties of the paper.

5. What are the common causes of web breaks in a Fourdrinier machine?

Web breaks can occur due to various reasons in a Fourdrinier machine, including:

- Improper sheet formation or weak spots in the web

- Variations in moisture content or basis weight across the web

- Foreign objects or contaminants in the stock

- Excessive tension or draw in the machine

- Improperly set or damaged rolls or bearings

- Electrical or mechanical malfunctions

- Operator error or lack of attention

6. How would you troubleshoot a problem with poor sheet formation on a Fourdrinier machine?

Troubleshooting poor sheet formation in a Fourdrinier machine involves a systematic approach:

- Check the headbox: Ensure proper slice adjustment, uniform stock flow, and absence of contaminants.

- Inspect the wire section: Check the wire tension, drainage, and alignment.

- Examine the press section: Verify press roll pressure, felt condition, and draw control.

- Analyze the dryer section: Investigate temperature profiles, air circulation, and web tension.

- Review the calender stack: Check roll settings, temperature, and web tension.

- Consider stock properties: Adjust fiber furnish, additives, and pH to improve sheet formation.

7. Describe the role of quality control in the operation of a Fourdrinier machine?

Quality control is crucial in ensuring the production of paper that meets customer specifications and industry standards.

- Regular monitoring: Continuously checking machine parameters, stock properties, and paper quality to identify deviations.

- Corrective actions: Taking prompt and appropriate measures to address quality issues and maintain optimal machine performance.

- Record keeping: Maintaining detailed records of quality control data, including test results, adjustments, and corrective actions.

- Customer feedback: Monitoring customer feedback and incorporating it into quality improvement initiatives.

8. Explain the importance of safety in operating a Fourdrinier machine?

Operating a Fourdrinier machine involves working with heavy equipment, moving parts, and hazardous substances, making safety a paramount concern:

- Personal protective equipment: Wearing appropriate PPE, such as gloves, safety glasses, and hearing protection, is essential.

- Machine guarding: Ensuring all moving parts and hazardous areas are adequately guarded to prevent accidents.

- Lockout/tagout procedures: Strictly adhering to established procedures for isolating and de-energizing equipment during maintenance or repairs.

- Emergency response: Being familiar with emergency procedures, including fire drills and evacuation routes.

9. What are the key performance indicators used to evaluate the effectiveness of a Fourdrinier machine?

Various KPIs are used to assess the performance of a Fourdrinier machine, including:

- Machine speed: The average speed at which the machine operates.

- Production rate: The amount of paper produced per unit of time.

- Sheet quality: The physical and optical properties of the paper, such as strength, smoothness, and brightness.

- Downtime: The percentage of time the machine is not producing paper due to maintenance, repairs, or other issues.

- Energy consumption: The amount of energy required to operate the machine.

- Operating costs: The expenses associated with running the machine, including raw materials, labor, and maintenance.

10. What are the latest advancements in Fourdrinier machine technology?

The papermaking industry is constantly evolving, and Fourdrinier machines are no exception.

- Advanced control systems: Utilizing sensors and automation to optimize machine performance and reduce variability.

- Improved headbox designs: Enhancing fiber distribution and sheet formation for better paper quality.

- Innovative drying technologies: Incorporating infrared heaters or microwave drying to improve energy efficiency and reduce drying times.

- Virtual reality simulators: Providing operators with immersive training experiences to enhance safety and efficiency.

- Data analytics: Using advanced algorithms to analyze machine data and identify areas for improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fourdrinier Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fourdrinier Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Fourdrinier Machine Tender is responsible for the safe and efficient operation of the Fourdrinier paper machine. This role plays a crucial role in the production of high-quality paper products. Key job responsibilities include:

1. Machine Operation and Monitoring

Operating and monitoring the Fourdrinier machine to ensure smooth and consistent production of paper. This involves controlling various machine parameters such as speed, temperature, and pressure to optimize paper quality.

2. Quality Control

Maintaining the desired paper quality by monitoring and adjusting process variables, such as stock consistency, pH levels, and fiber composition. Conducting regular tests and inspections to ensure adherence to quality standards and specifications.

3. Troubleshooting and Maintenance

Identifying and resolving operational issues by diagnosing machine faults and performing necessary repairs and adjustments. Conducting routine maintenance tasks to ensure machine reliability and prevent breakdowns.

4. Safety and Compliance

Strictly adhering to safety protocols and industry regulations. Maintaining a clean and organized work environment. Following established procedures to prevent accidents and ensure compliance with environmental standards.

Interview Tips

To ace an interview for the Fourdrinier Machine Tender role, it is essential to prepare thoroughly and showcase your skills and knowledge. Here are some interview tips:

1. Research and Practice

Research the company, the industry, and the specific job description to understand their requirements. Practice answering common interview questions related to paper production, machine operation, quality control, and safety.

2. Highlight Relevant Experience

Emphasize your experience in operating and maintaining paper machines, and demonstrate your ability to resolve operational issues and maintain quality standards. If possible, quantify your achievements to showcase your impact.

3. Showcase Technical Knowledge

Demonstrate your understanding of papermaking processes, machine components, and quality control techniques. Be prepared to discuss process parameters, troubleshooting methods, and safety protocols.

4. Prepare for Behavioral Questions

Be ready to answer behavioral interview questions that evaluate your teamwork, problem-solving abilities, and commitment to safety. Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your experiences.

5. Be Enthusiastic and Professional

Show enthusiasm for the role and the paper industry. Maintain a positive attitude, be respectful, and dress professionally. Punctuality and preparedness will make a good impression on the interviewers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fourdrinier Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!