Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fourdrinier Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

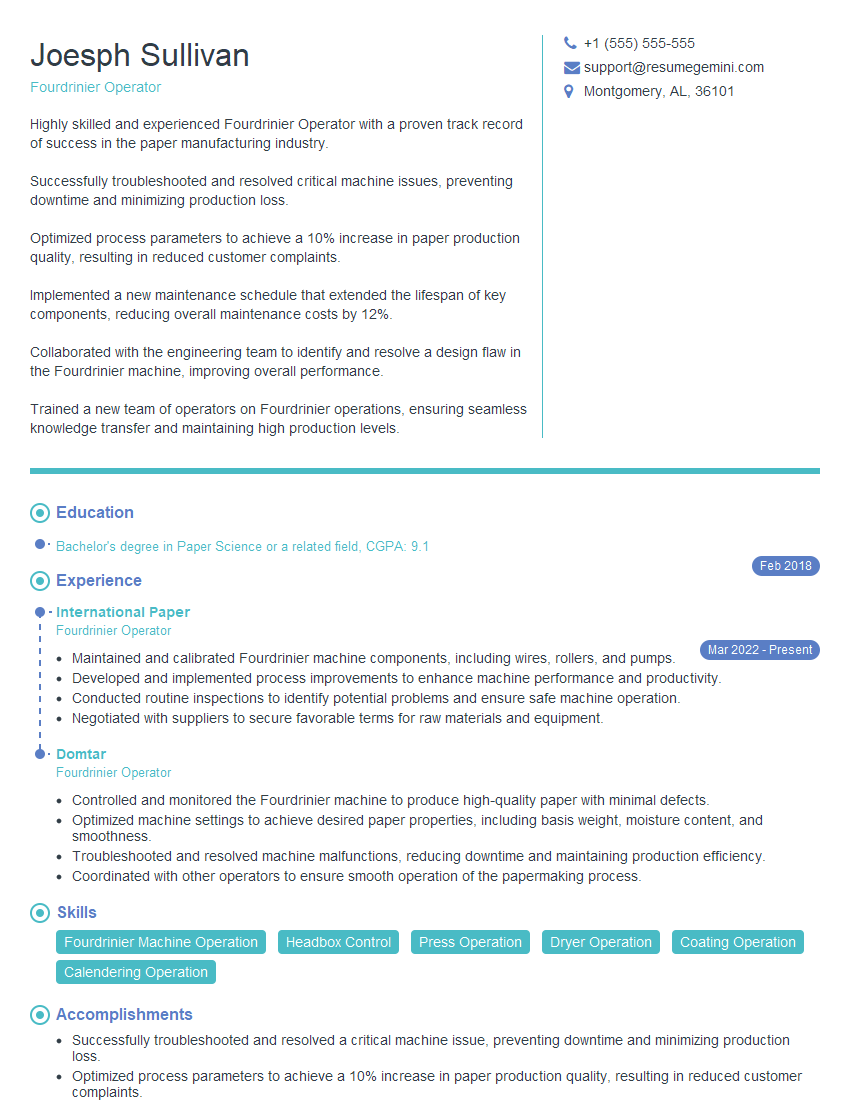

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fourdrinier Operator

1. Describe the process of Fourdrinier papermaking machine?

The Fourdrinier papermaking machine is a continuous process that converts wood pulp into paper. The process begins with the preparation of the pulp, which is made from wood chips that have been pulped and mixed with water. The pulp is then fed onto a wire mesh conveyor belt, where it is spread out and formed into a sheet. The sheet is then pressed to remove excess water and dried, and finally, it is rolled into a finished product.

2. How do you troubleshoot a Fourdrinier machine when the paper is breaking?

Paper Breaks Troubleshooting:

- Check the consistency of the pulp.

- Check the pH of the pulp.

- Check the flow of the pulp.

- Check the tension of the wire.

- Check the speed of the machine.

- Check the condition of the wire.

- Check the condition of the rolls.

- Check the condition of the bearings.

3. What are the different types of Fourdrinier machines?

There are two main types of Fourdrinier machines: the gravity-fed machine and the vacuum-fed machine. The gravity-fed machine is the most common type, and it uses gravity to draw the pulp onto the wire. The vacuum-fed machine uses a vacuum to draw the pulp onto the wire, which allows for a more even distribution of the pulp and a higher quality paper.

4. What are the advantages and disadvantages of Fourdrinier machines?

Advantages:

- High production rates.

- Can produce a wide variety of paper grades.

- Relatively low operating costs.

Disadvantages:

- Complex to operate and maintain.

- Can be sensitive to changes in raw materials and operating conditions.

- Can produce a lot of waste.

5. What are the key factors that affect the quality of paper produced on a Fourdrinier machine?

- The consistency of the pulp.

- The pH of the pulp.

- The flow of the pulp.

- The tension of the wire.

- The speed of the machine.

- The condition of the wire.

- The condition of the rolls.

- The condition of the bearings.

6. What are the safety hazards associated with operating a Fourdrinier machine?

- Moving parts.

- Electrical hazards.

- Chemical hazards.

- Noise hazards.

- Heat hazards.

7. What are the maintenance requirements for a Fourdrinier machine?

- Regular cleaning and inspection.

- Replacement of worn parts.

- Lubrication.

- Calibration.

8. What are the different types of paper that can be produced on a Fourdrinier machine?

- Newsprint.

- Printing and writing papers.

- Packaging papers.

- Specialty papers.

9. What is the role of the Fourdrinier operator?

The Fourdrinier operator is responsible for the operation and maintenance of the Fourdrinier papermaking machine. The operator must have a thorough understanding of the machine and its operation, and must be able to troubleshoot and repair any problems that may arise.

10. What are the qualifications required to be a Fourdrinier operator?

- High school diploma or equivalent.

- Experience in operating and maintaining papermaking machinery.

- Knowledge of papermaking processes.

- Ability to troubleshoot and repair mechanical and electrical problems.

- Strong communication and interpersonal skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fourdrinier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fourdrinier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Fourdrinier Operator plays a crucial role in the papermaking process by operating the Fourdrinier machine, a vital component in the production of paper. The primary responsibilities of this position include:

1. Machine Operation

The Fourdrinier Operator is entrusted with the safe and efficient operation of the Fourdrinier machine. They must ensure that the machine is running smoothly and producing quality paper.

- Effectively operate, monitor, and maintain all aspects of the Fourdrinier machine, including wire and press sections.

- Control the papermaking process by adjusting machine parameters, such as stock flow, machine speed, and tension.

2. Troubleshooting and Maintenance

When issues arise, the Fourdrinier Operator is responsible for troubleshooting and resolving them promptly to minimize downtime. They also perform routine maintenance to keep the machine in optimal condition.

- Quickly diagnose and troubleshoot machine malfunctions and take corrective actions.

- Perform preventative maintenance tasks, such as cleaning, lubricating, and inspecting machine components.

3. Quality Control

Ensuring the quality of the paper produced is a critical aspect of the Fourdrinier Operator’s role. They monitor the paper’s properties and make adjustments to the machine parameters as needed.

- Monitor and control paper quality parameters, such as basis weight, moisture content, and opacity.

- Conduct regular quality checks and make adjustments to the machine settings to maintain desired specifications.

4. Process Optimization

The Fourdrinier Operator continually seeks ways to improve the efficiency and productivity of the papermaking process by identifying areas for optimization.

- Analyze production data and identify opportunities for process optimization to improve efficiency and reduce waste.

- Collaborate with other team members, including engineers and operators, to implement process improvements.

Interview Tips

Preparing thoroughly for an interview is essential to showcase your skills and increase your chances of success. Here are some tips and tricks to help you ace your interview for a Fourdrinier Operator position:

1. Research the Company and Position

Take the time to research the company’s website, industry news, and the specific requirements of the Fourdrinier Operator position. This will demonstrate your interest in the role and the company.

- Visit the company’s website and read about their history, values, and products/services.

- Review the job description carefully to understand the key responsibilities, requirements, and expectations.

2. Practice Answering Common Interview Questions

Anticipate potential interview questions and prepare your answers in advance. This will help you feel confident and articulate during the interview.

- Prepare answers to general interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Practice answering technical questions related to the job responsibilities, such as “Describe your experience operating a Fourdrinier machine.”

3. Highlight Your Experience and Skills

Emphasize your relevant experience and skills that align with the job requirements. Use specific examples to demonstrate your abilities and how they have benefited previous employers.

- Quantify your accomplishments whenever possible, using metrics and data to support your claims.

- Be prepared to discuss your experience with troubleshooting and resolving machine malfunctions.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any details and gain insights into the company culture.

- Ask questions about the company’s growth plans, the training and development opportunities available, and the company’s commitment to safety.

- Be prepared to ask specific questions related to the Fourdrinier machine and the papermaking process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fourdrinier Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.