Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fractionating Still Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fractionating Still Operator so you can tailor your answers to impress potential employers.

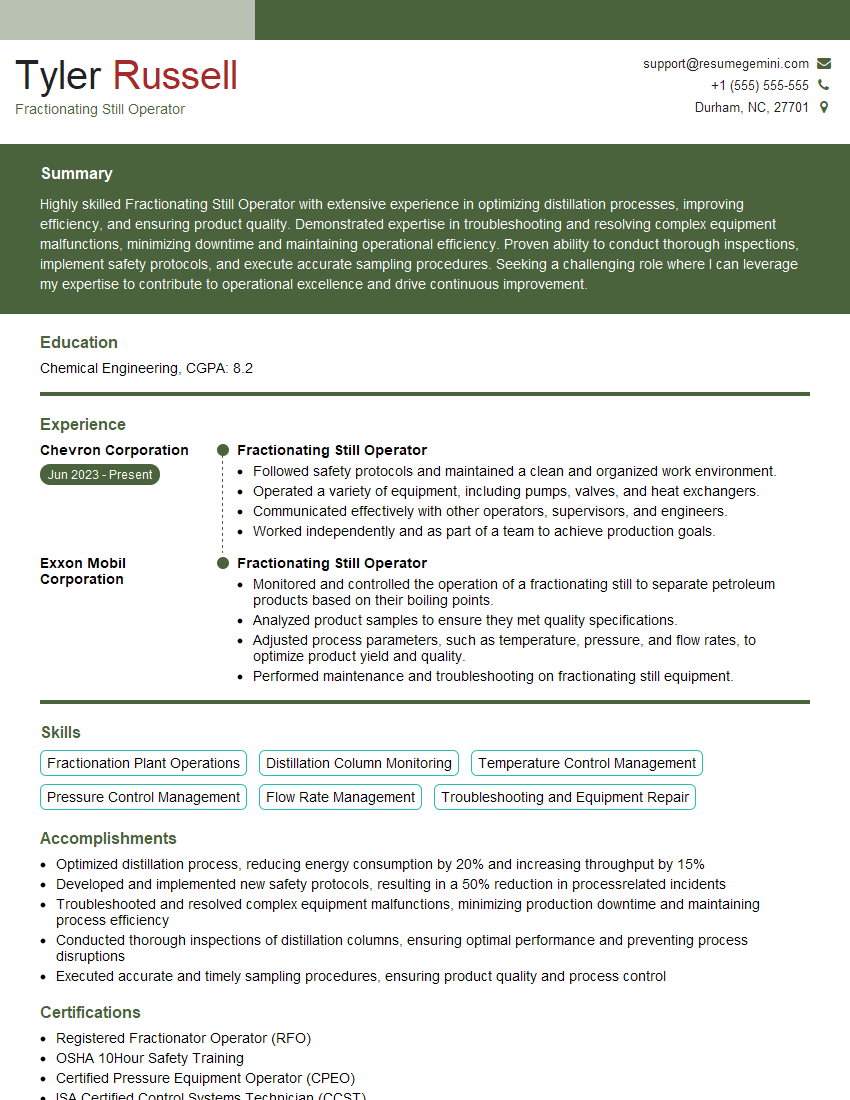

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fractionating Still Operator

1. Describe your understanding of the role of a Fractionating Still Operator.

A Fractionating Still Operator is responsible for operating and maintaining fractionating stills, which are used to separate liquids based on their boiling points. In this role, I would be responsible for tasks such as:

- Monitoring and controlling the temperature, pressure, and flow rates of the distillation process.

- Making adjustments to the still’s operation to optimize yield and purity of the desired fractions.

- Ensuring that the still is operating safely and efficiently, and troubleshooting any problems that may arise.

2. Explain the principles of fractional distillation.

Vacuum Distillation

- Vacuum distillation is a process that is used to separate liquids that have high boiling points.

- By reducing the pressure in the distillation apparatus, the boiling points of the liquids are lowered, making it possible to separate them at lower temperatures.

Steam Distillation

- Steam distillation is a process that is used to separate liquids that are immiscible with water.

- Steam is passed through the mixture of liquids, and the vapors are condensed and collected.

- The liquids can then be separated based on their different boiling points.

3. How do you ensure the safety of the distillation process?

Ensuring the safety of the distillation process is paramount. Here are some key measures I would take:

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Be aware of the potential hazards of the chemicals being used and take appropriate precautions.

- Follow all safety protocols and procedures, including those for handling flammable liquids and gases.

- Never leave the distillation apparatus unattended while it is in operation.

- Be prepared to respond to any emergencies that may arise, such as fires or spills.

4. What types of maintenance tasks are required for a fractionating still?

To ensure optimal performance and safety, regular maintenance tasks are essential for a fractionating still. These tasks may include:

- Cleaning the still and its components to remove any buildup or residue.

- Inspecting the still for any signs of damage or wear and tear.

- Calibrating the still’s instruments to ensure accuracy.

- Replacing any worn or damaged parts.

- Performing regular maintenance checks and troubleshooting any issues that may arise.

5. How do you troubleshoot common problems that can occur during fractional distillation?

Troubleshooting common problems during fractional distillation is crucial to maintaining efficiency and safety. Here are some common issues and their potential solutions:

- Low yield: Check the efficiency of the condenser, ensure proper packing of the column, and optimize the reflux ratio.

- Contamination: Identify the source of contamination, clean the still thoroughly, and use high-purity solvents.

- Column flooding: Reduce the feed rate, increase the reflux ratio, or check for any blockages in the column.

- Excessive pressure: Check for blockages in the condenser or lines, adjust the flow rates, and ensure proper vacuum control.

- Leaking: Inspect all connections and seals, tighten them if necessary, and replace any damaged components.

6. Describe the importance of temperature control in fractional distillation.

Temperature control is critical in fractional distillation as it directly affects the separation of components. By carefully controlling the temperature, the operator can:

- Ensure that the desired components vaporize and condense at the appropriate temperatures.

- Maximize the separation of components with close boiling points.

- Prevent thermal degradation of temperature-sensitive compounds.

- Maintain a stable and efficient distillation process.

7. How do you determine the optimal reflux ratio for a given distillation?

Determining the optimal reflux ratio is essential for achieving the desired separation. Here’s how I approach it:

- Consider the volatility of the components: More volatile components require a higher reflux ratio.

- Evaluate the desired purity: A higher reflux ratio leads to higher purity but may reduce yield.

- Assess the column efficiency: A more efficient column allows for a lower reflux ratio.

- Monitor the distillate composition: Adjust the reflux ratio based on the composition of the distillate to achieve the target purity.

8. Explain the role of packing in a fractionating column.

Packing in a fractionating column plays a vital role in enhancing the separation process:

- Increases surface area: Packing provides a large surface area for vapor-liquid contact, improving mass transfer.

- Promotes reflux: Packing facilitates the condensation and reflux of vapors, increasing the number of theoretical plates.

- Reduces pressure drop: Proper packing design minimizes pressure drop, ensuring efficient flow of vapors through the column.

- Improves separation: The increased surface area and reflux promote better separation of components with similar boiling points.

9. How do you handle waste generated during fractional distillation?

Proper waste management is crucial in fractional distillation. I would adhere to the following practices:

- Identify and classify waste: Determine the type of waste generated (e.g., solvents, residues, contaminated materials).

- Follow safety protocols: Handle and dispose of waste according to safety regulations and guidelines.

- Minimize waste production: Optimize distillation parameters to reduce waste generation.

- Utilize waste reduction techniques: Implement methods like solvent recovery or recycling to minimize waste disposal.

- Comply with environmental regulations: Ensure proper disposal and documentation to meet environmental compliance requirements.

10. Describe your experience in using analytical techniques to monitor the progress of a distillation.

Throughout my experience, I have utilized various analytical techniques to monitor the progress of distillation:

- Gas chromatography (GC): Analyze the composition of the distillate and determine the purity of the fractions.

- High-performance liquid chromatography (HPLC): Separate and identify components in complex mixtures.

- Refractive index measurement: Monitor the purity of the distillate based on changes in refractive index.

- Boiling point determination: Measure the boiling points of the fractions to assess their purity and volatility.

- Spectroscopic techniques: Utilize UV-Vis or IR spectroscopy to identify and characterize specific compounds.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fractionating Still Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fractionating Still Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fractionating Still Operator plays a crucial role in the chemical industry, ensuring the efficient and safe operation of fractionation stills.

1. Operating Fractionation Stills

The primary responsibility of a Fractionating Still Operator is to operate and control fractionation stills. This involves:

- Monitoring and adjusting process variables such as temperature, pressure, and flow rates to optimize product quality.

- Ensuring the proper functioning of all equipment and instrumentation associated with the still.

- Performing maintenance and repairs on the still as needed.

2. Quality Control

Fractionating Still Operators are responsible for maintaining the quality of the products produced by the still. This includes:

- Collecting and analyzing product samples to ensure they meet specifications.

- Adjusting process parameters to correct any deviations in product quality.

- Maintaining records of all quality control tests performed.

3. Safety and Environmental Compliance

Fractionating Still Operators must prioritize safety and environmental compliance in all aspects of their work. This involves:

- Following all safety protocols and procedures.

- Wearing appropriate personal protective equipment (PPE).

- Monitoring for potential hazards and taking corrective action to mitigate risks.

- Ensuring compliance with all environmental regulations related to the operation of the still.

4. Troubleshooting and Problem-Solving

Fractionating Still Operators must possess strong troubleshooting and problem-solving skills to handle any issues that may arise during the operation of the still. This involves:

- Identifying and diagnosing operational problems.

- Developing and implementing solutions to correct these problems.

- Working with other team members to resolve complex issues.

Interview Tips

Preparing thoroughly for an interview for a Fractionating Still Operator position can significantly increase your chances of success. Here are some tips:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s culture, values, and the requirements of the role.

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to encounter in an interview for a Fractionating Still Operator position. Practice answering these questions in advance, focusing on highlighting your relevant skills and experience.

3. Prepare Questions for the Interviewer

Asking thoughtful questions during an interview demonstrates your interest in the position and the company. Prepare a few questions that you can ask the interviewer, such as about the company’s growth plans or the specific responsibilities of the role.

4. Dress Professionally and Arrive on Time

The way you present yourself at an interview can have a strong impact on the interviewer’s perception of you. Dress professionally and arrive on time to show that you are serious about the opportunity.

5. Be Confident and Enthusiastic

Confidence and enthusiasm can go a long way in an interview. Believe in your abilities and demonstrate your passion for the role and the industry. Your positive attitude can make a memorable impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fractionating Still Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!