Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Frame Table Operator Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

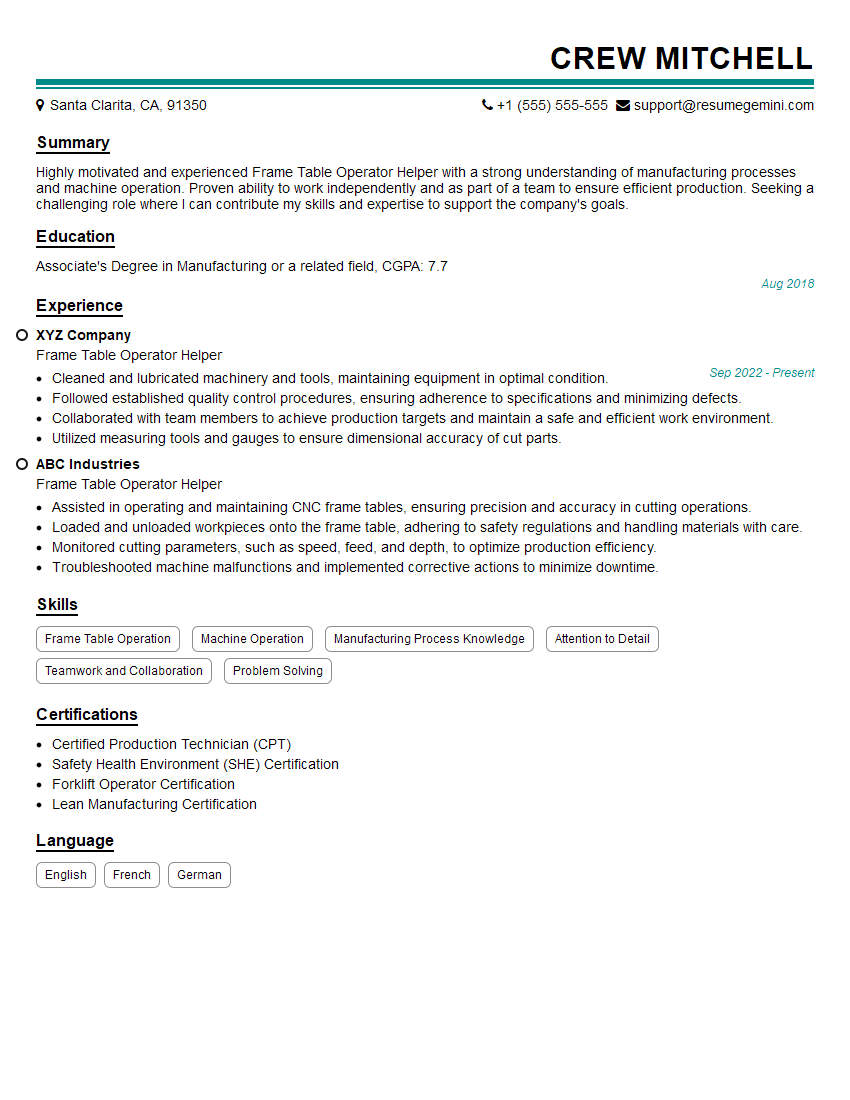

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Frame Table Operator Helper

1. Describe the process of setting up a frame table for a screen printing operation.

As a Frame Table Operator Helper, I would be responsible for assisting in setting up the frame table for screen printing operations. This process typically includes the following steps:

- Selecting the appropriate frame size and mesh count for the printing job

- Stretching the screen fabric over the frame and securing it tightly

- Aligning the frame with the table and securing it in place

- Preparing the emulsion and applying it to the screen using a scoop coater

- Exposing the emulsion to light through a positive film to create the desired printing pattern

- Washing out the unexposed emulsion to create the stencil

- Drying and curing the stencil

2. Explain the importance of maintaining proper tension during the frame stretching process.

Understanding Tension

- Proper tension is crucial in screen printing as it ensures accurate print registration and prevents distortion or stretching of the image.

- Too loose tension can result in blurry prints, while excessive tension can damage the screen fabric or cause the frame to warp.

Maintaining Proper Tension

- Use a tension meter to measure and adjust the tension evenly across the entire frame.

- Start from the center and work outwards, applying even pressure to each side.

- For large frames, use a tensioning machine to achieve optimal tension.

3. What safety precautions should be taken when handling chemicals used in screen printing?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a respirator when necessary.

- Read and understand the MSDS for each chemical used.

- Handle chemicals in a well-ventilated area to avoid inhalation.

- Avoid skin contact with chemicals, and wash thoroughly if contact occurs.

- Dispose of chemicals properly according to environmental regulations.

4. Describe the different types of squeegees used in screen printing and their respective applications.

- Hard Squeegees: Durable and long-lasting, used for printing on thick materials like cardboard or textiles.

- Soft Squeegees: Flexible and conform to uneven surfaces, suitable for printing on delicate fabrics or complex designs.

- Medium Squeegees: Versatile and commonly used for general printing applications.

- Rounded Squeegees: Feature a rounded edge, ideal for printing on curved or cylindrical surfaces.

- Squeegee Hardness: Measured in durometers (Duro), higher durometer values indicate harder squeegees.

5. Explain the concept of off-contact printing and its benefits.

- Concept: Off-contact printing creates a small gap between the screen and the substrate during printing. Benefits:

- Reduces ink squeeze-out, resulting in sharper prints.

- Prevents the screen from sticking to the substrate.

- Allows for printing on uneven surfaces.

6. Discuss the factors that affect the thickness of the ink deposit in screen printing.

- Ink Viscosity: Thicker inks result in thicker deposits.

- Squeegee Pressure: Higher pressure transfers more ink.

- Screen Mesh Count: Finer mesh counts produce thinner deposits.

- Off-Contact Distance: Greater distance leads to thinner deposits.

- Substrate Characteristics: Absorbent substrates require more ink.

7. Explain the role of a flash cure unit in screen printing and when it is typically used.

- Purpose: A flash cure unit uses heat to partially cure the ink, allowing for handling and overprinting without smudging. Applications:

- Multi-color printing: Flash curing between colors prevents mixing.

- Printing on heat-sensitive substrates: Gradual curing prevents damage.

- Improving ink adhesion on difficult surfaces.

8. Describe the different methods used to clean screen printing screens and their effectiveness.

- Water-Based Cleaners: Environmentally friendly, suitable for water-based inks.

- Solvent-Based Cleaners: More effective for oil-based inks, but require proper ventilation.

- Pressure Washing: Uses high-pressure water to remove ink and debris, suitable for large screens.

- Ultrasonic Cleaning: Immerse screens in a heated cleaning solution agitated by ultrasonic waves, effective for removing stubborn residue.

9. Explain the importance of proper storage and handling of screen printing screens to maintain their longevity.

- Storage: Store screens in a cool, dry place away from direct sunlight.

- Handling: Use clean gloves and avoid touching the printing surface.

- Cleaning: Remove ink and debris promptly to prevent clogging mesh openings.

- Inspection: Regularly inspect screens for damage and repair any defects promptly.

10. Describe the role of a Frame Table Operator Helper in maintaining the overall efficiency of a screen printing operation.

- Assisting in setting up and maintaining frame tables.

- Preparing and stretching screens to ensure proper tension.

- Loading and unloading screens from the printing press.

- Cleaning and maintaining screens and equipment.

- Monitoring the printing process and identifying any potential issues.

- Communicating with operators and supervisors to ensure smooth workflow.

- Maintaining a clean and organized work area.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Frame Table Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Frame Table Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Frame Table Operator Helper is responsible for assisting the Frame Table Operator in the production of precision metal parts. Key responsibilities include:

1. Material Handling

loading and unloading materials from the frame table

- Ensuring that materials are properly aligned and secured

- Monitoring material flow and making adjustments as needed

2. Machine Operation

monitoring the frame table machine to ensure that it is operating properly

- Making minor adjustments to the machine as needed

- Reporting any problems or malfunctions to the Frame Table Operator

3. Quality Control

inspecting parts produced by the frame table machine for defects

- Identifying and removing defective parts

- Maintaining records of quality control checks

4. Safety

following all safety procedures and regulations

- Wearing appropriate safety gear

- Keeping the work area clean and organized

Interview Tips

To ace an interview for a Frame Table Operator Helper position, candidates should:

1. Research the company and the position

This will help you understand the company’s culture, values, and expectations for the role.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work for the company

2. Practice your answers to common interview questions

This will help you feel more confident and prepared during the interview.

- Use the STAR method to answer questions

- Be specific and provide examples

- Quantify your accomplishments whenever possible

3. Dress professionally

First impressions matter, so make sure you dress appropriately for the interview.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Pay attention to your grooming

4. Be on time

Punctuality shows that you are respectful of the interviewer’s time.

- Plan your route in advance

- Give yourself plenty of time to get to the interview

- If you are running late, call or email the interviewer to let them know

5. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic about the job and about working for the company. Show your passion for the role and your positive attitude during the interview.

- Smile and make eye contact

- Be polite and respectful

- Ask questions about the company and the position

Next Step:

Now that you’re armed with the knowledge of Frame Table Operator Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Frame Table Operator Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini