Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fretted Instrument Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

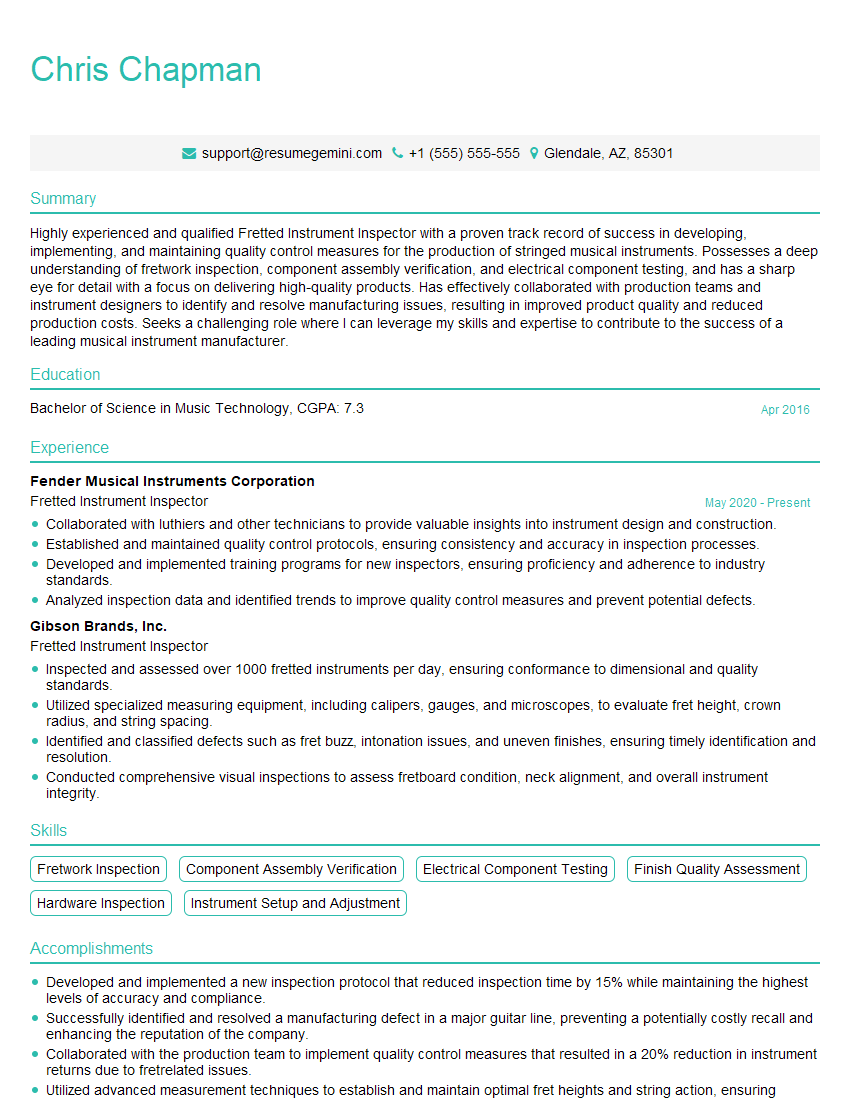

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fretted Instrument Inspector

1. How would you inspect the intonation of a guitar?

To inspect guitar intonation, I would first check the tuner to ensure the guitar is in tune. Then, I would play each string at the 12th fret and compare the pitch to the open string.

- If the string is sharp at the 12th fret, the bridge saddle needs to be moved back towards the tailpiece.

- If the string is flat at the 12th fret, the bridge saddle needs to be moved forward towards the nut.

2. What are the key factors to consider when inspecting the neck of a guitar?

When inspecting a guitar neck, several factors must be considered:

Neck Relief

- Check if there is a gap between the strings and the fingerboard at the seventh fret.

- The gap should be around 0.010 inches

- Adjust the truss rod to achieve the correct neck relief.

Neck Bow and Twist

- Lay a straightedge along the side of the neck from the nut to the bridge.

- Check for any gaps between the straightedge and the neck.

- Adjust the truss rod to correct any bowing or twisting.

Fret Leveling

- Check that the frets are level using a fret rocker.

- Level the frets with a fret file if any are uneven.

3. How would you identify and repair a loose or rattling fret?

To identify a loose or rattling fret, I would tap on each fret with a rubber mallet. If a fret is loose, it will produce a dull sound or rattle.

To repair a loose fret, I would remove the string above the fret and use a fret puller to gently pull the fret out of the slot. I would then clean the slot and the bottom of the fret, apply some fret glue, and press the fret back into place. I would then recrown the fret and polish it.

4. What are the common causes of buzzing on a fretted instrument?

Common causes of fret buzz on a fretted instrument include:

- Loose or rattling frets

- Improper neck relief

- High action (distance from the strings to the fingerboard)

- Worn or uneven frets

- Loose or rattling truss rod

5. How would you inspect the electronics of an electric guitar?

To inspect an electric guitar’s electronics, I would first check the output jack to ensure it is securely connected. I would then use a multimeter to check the continuity of the pickups, selector switch, and volume and tone pots.

- I would also check the soldering joints on all the electronic components to ensure they are clean and secure.

- Finally, I would plug the guitar into a amplifier and test all the pickup positions and controls to ensure they are functioning properly.

6. What are the different types of finishes used on fretted instruments?

The different types of finishes used on fretted instruments include:

- Nitrocellulose lacquer

- Polyurethane

- Acrylic

- Oil-based finishes (such as tung oil or linseed oil)

- Wax finishes

Each type of finish has its advantages and disadvantages, so the choice of finish depends on the desired look, feel, and tone of the instrument.

7. How would you repair a cracked guitar body?

To repair a cracked guitar body, I would first clean the crack and surrounding area with a damp cloth. I would then apply a thin layer of wood glue to the crack and clamp it together. I would use a soft cloth between the clamp and the guitar to prevent damage to the finish.

- Once the glue has dried, I would sand the area smooth and apply a touch-up finish to match the rest of the guitar.

8. What are the common causes of a guitar going out of tune?

The common causes of a guitar going out of tune are:

- Changes in temperature or humidity can affect the tension of the strings, causing them to go out of tune.

- Loose tuning pegs or a slipping nut can allow the strings to slip, causing the guitar to go out of tune.

- Stretching or breaking in new strings can also cause the guitar to go out of tune.

- A damaged or worn-out bridge or nut can also cause the guitar to go out of tune.

9. How would you troubleshoot a problem with a guitar’s pickup?

To troubleshoot a problem with a guitar’s pickup, I would first check the output jack to ensure it is securely connected. I would also check the continuity of the pickup with a multimeter.

- If the pickup is not receiving power, I would check the wiring and solder joints to ensure they are secure.

- If the pickup is receiving power but not producing any sound, I would check the pickup’s magnets and coils for damage.

10. What are the different types of guitar strings?

The main types of acoustic and electric guitar strings are:

- Acoustic guitar strings: Steel strings, nylon strings, fluorocarbon strings

- Electric guitar strings: Nickel-plated steel strings, stainless steel strings, cobalt strings

Each type of string has a unique sound and feel, so the choice of string depends on the desired tone and playing style.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fretted Instrument Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fretted Instrument Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fretted Instrument Inspectors play a crucial role in the musical instrument industry, ensuring the quality and playability of stringed instruments like guitars, basses, and mandolins.

1. Inspection and Quality Control

Inspecting instruments for defects, including blemishes, finish issues, and structural problems.

- Ensuring that instruments meet established quality standards and customer specifications.

- Identifying and documenting any discrepancies or issues that need to be addressed.

2. Fretwork Verification

Checking the fretwork of instruments for accuracy and consistency.

- Using specialized tools to measure fret height, spacing, and intonation.

- Adjusting frets as needed to ensure optimal playability and sound quality.

3. Playability Assessment

Evaluating the overall playability of instruments.

- Testing neck relief, string height, and intonation.

- Ensuring that instruments are comfortable to hold, play, and produce a clear, resonant sound.

4. Documentation and Communication

Maintaining detailed inspection records and reporting any issues or concerns.

- Communicating with production teams, quality assurance managers, and customers regarding inspection results and corrective actions.

- Providing feedback on instrument design and manufacturing processes to improve quality.

Interview Tips

To ace an interview for a Fretted Instrument Inspector position, there are several key tips and preparation strategies that candidates should follow.

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and product line.

- Review the job description carefully and identify the key responsibilities and requirements.

- Tailor your answers to the specific needs and expectations of the company and role.

2. Emphasize Your Expertise

Highlight your experience and knowledge in fretted instrument inspection.

- Discuss your understanding of fretwork, playability assessment, and quality control processes.

- Provide examples of how you have successfully identified and resolved issues with fretted instruments.

3. Showcase Your Attention to Detail

Demonstrate your sharp observation skills and ability to identify even the smallest defects.

- Explain how you go about inspecting instruments, using examples of specific areas you focus on.

- Emphasize your systematic approach and willingness to take the time to ensure accuracy.

4. Prepare for Technical Questions

Anticipate technical questions related to fretted instruments and inspection techniques.

- Be prepared to discuss fret height measurement tools, intonation adjustment procedures, and playability assessment methods.

- Practice answering questions about the causes and solutions for common fretted instrument problems.

5. Be Passionate and Enthusiastic

Convey your love for music and your passion for ensuring that fretted instruments are of the highest quality.

- Explain how your interest in music and instruments motivates you to excel in your work.

- Share examples of how you have used your expertise to enhance the playing experience for musicians.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fretted Instrument Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!