Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Friction Paint Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

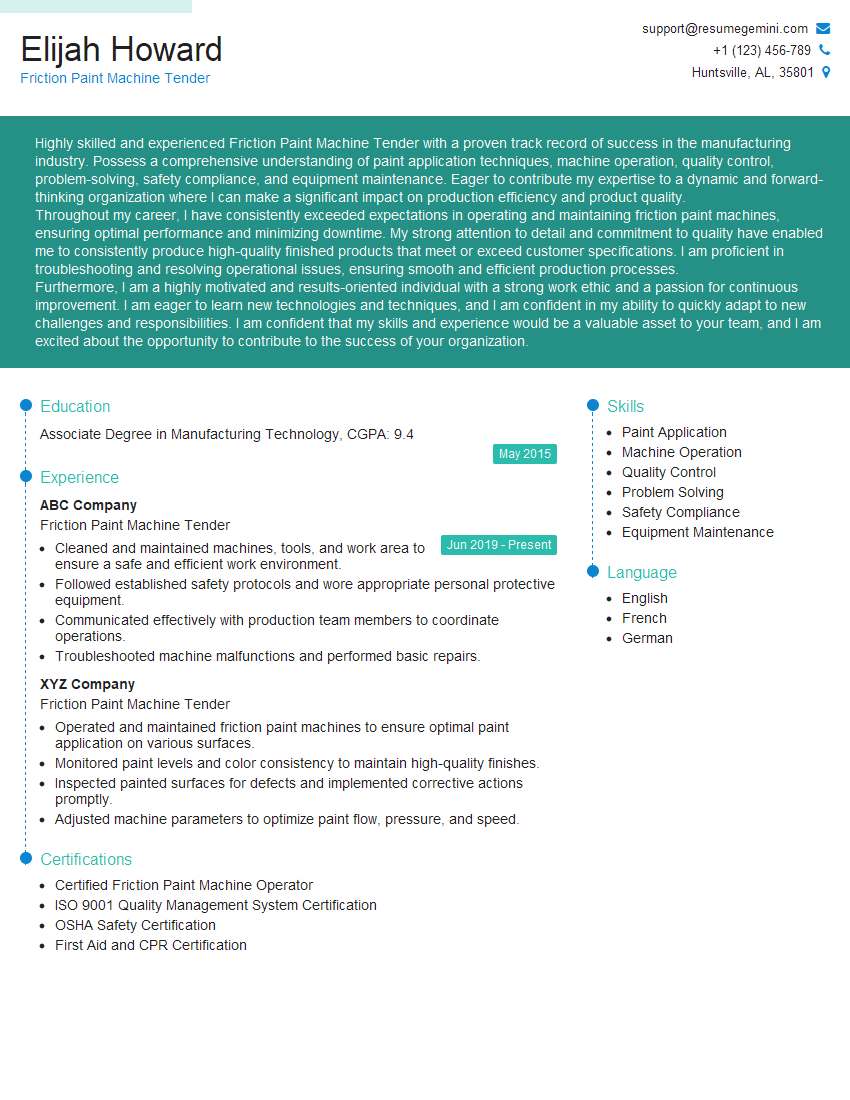

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Friction Paint Machine Tender

1. What are the main components of a friction paint machine?

The main components of a friction paint machine include:

- A drive motor

- A transmission

- A friction plate

- A paint roller

- A paint reservoir

- A control panel

2. How does a friction paint machine work?

A friction paint machine works by using a rotating friction plate to apply paint to a surface. The friction plate is made of a material that creates friction when it comes into contact with the surface, which causes the paint to be transferred from the friction plate to the surface.

3. What are the different types of paint that can be used with a friction paint machine?

The type of paint that can be used with a friction paint machine depends on the specific machine. However, most friction paint machines can use latex paint, acrylic paint, and enamel paint.

4. What are the advantages of using a friction paint machine?

There are several advantages to using a friction paint machine, including:

- Friction paint machines are relatively inexpensive to purchase and operate.

- Friction paint machines are easy to use and do not require any special training.

- Friction paint machines can be used to apply paint to a variety of surfaces, including wood, metal, and plastic.

- Friction paint machines can be used to apply paint in a variety of thicknesses, from thin coats to thick coats.

5. What are the disadvantages of using a friction paint machine?

There are also some disadvantages to using a friction paint machine, including:

- Friction paint machines can be noisy when they are in operation.

- Friction paint machines can create a lot of dust when they are in operation.

- Friction paint machines can be difficult to clean after they have been used.

6. What are the safety precautions that should be taken when using a friction paint machine?

When using a friction paint machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Make sure that the friction paint machine is properly grounded.

- Do not use the friction paint machine in a confined space.

- Do not use the friction paint machine in wet or damp conditions.

- Do not attempt to repair the friction paint machine yourself.

7. How do you troubleshoot a friction paint machine?

If you are experiencing problems with your friction paint machine, you can troubleshoot the problem by following these steps:

- Check to make sure that the friction paint machine is properly plugged in.

- Check to make sure that the friction plate is properly attached to the drive motor.

- Check to make sure that the paint reservoir is full.

- Check to make sure that the control panel is set to the correct settings.

- If you are still experiencing problems, you can contact the manufacturer of the friction paint machine for assistance.

8. What are the maintenance requirements for a friction paint machine?

The maintenance requirements for a friction paint machine are relatively simple. However, it is important to follow the manufacturer’s instructions for maintenance to ensure that the machine operates properly and lasts for a long time.

9. How do you clean a friction paint machine?

To clean a friction paint machine, follow these steps:

- Unplug the friction paint machine from the outlet.

- Remove the friction plate from the drive motor.

- Empty the paint reservoir.

- Clean the friction plate and the paint reservoir with a damp cloth.

- Dry the friction plate and the paint reservoir with a clean cloth.

- Reattach the friction plate to the drive motor.

- Plug the friction paint machine back into the outlet.

10. What are the different types of surfaces that can be painted with a friction paint machine?

A friction paint machine can be used to paint a variety of surfaces, including wood, metal, plastic, and glass. However, it is important to note that the type of paint that is used must be compatible with the surface that is being painted.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Friction Paint Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Friction Paint Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Friction Paint Machine Tenders are responsible for operating and maintaining friction paint machines, which apply paint to metal surfaces. Their key responsibilities include:

1. Machine Operation

Operate friction paint machines to apply paint to metal surfaces.

- Load and unload workpieces from the machine.

- Set up and adjust machine parameters, such as speed, pressure, and temperature.

2. Machine Maintenance

Perform routine maintenance on friction paint machines.

- Clean and lubricate machine components.

- Inspect machine parts for wear and tear.

- Make minor repairs and adjustments to the machine.

3. Paint Quality Control

Monitor the quality of paint applied to workpieces.

- Inspect workpieces for defects, such as scratches, dents, or uneven paint coverage.

- Make adjustments to the machine or paint mixture as needed to ensure paint quality meets specifications.

4. Safety and Compliance

Follow safety protocols and comply with environmental regulations.

- Wear appropriate personal protective equipment (PPE).

- Handle and dispose of paints and solvents safely.

- Maintain a clean and organized work area.

Interview Tips

To ace an interview for a Friction Paint Machine Tender position, candidates should prepare by familiarizing themselves with the key job responsibilities and demonstrating their skills and experience in these areas. Here are some tips:

1. Research the Company and Position

Learn about the company’s industry, products, and culture. Research the specific job requirements and responsibilities.

- Visit the company website and social media pages.

- Read industry news and articles.

2. Highlight Relevant Skills and Experience

Emphasize your experience operating and maintaining friction paint machines. Quantify your accomplishments and provide specific examples.

- Describe how you have improved paint quality or increased production efficiency.

- Highlight your ability to troubleshoot and resolve machine problems.

3. Demonstrate Safety and Compliance Knowledge

Show that you are aware of safety protocols and environmental regulations. Explain how you ensure a safe and compliant work environment.

- Describe your experience with PPE and hazardous material handling.

- Explain how you stay up-to-date on industry best practices.

4. Prepare Questions for the Interviewer

Ask thoughtful questions that demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more.

- Ask about the company’s growth plans.

- Inquire about opportunities for professional development.

Next Step:

Now that you’re armed with the knowledge of Friction Paint Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Friction Paint Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini