Are you gearing up for an interview for a Friction Saw Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Friction Saw Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

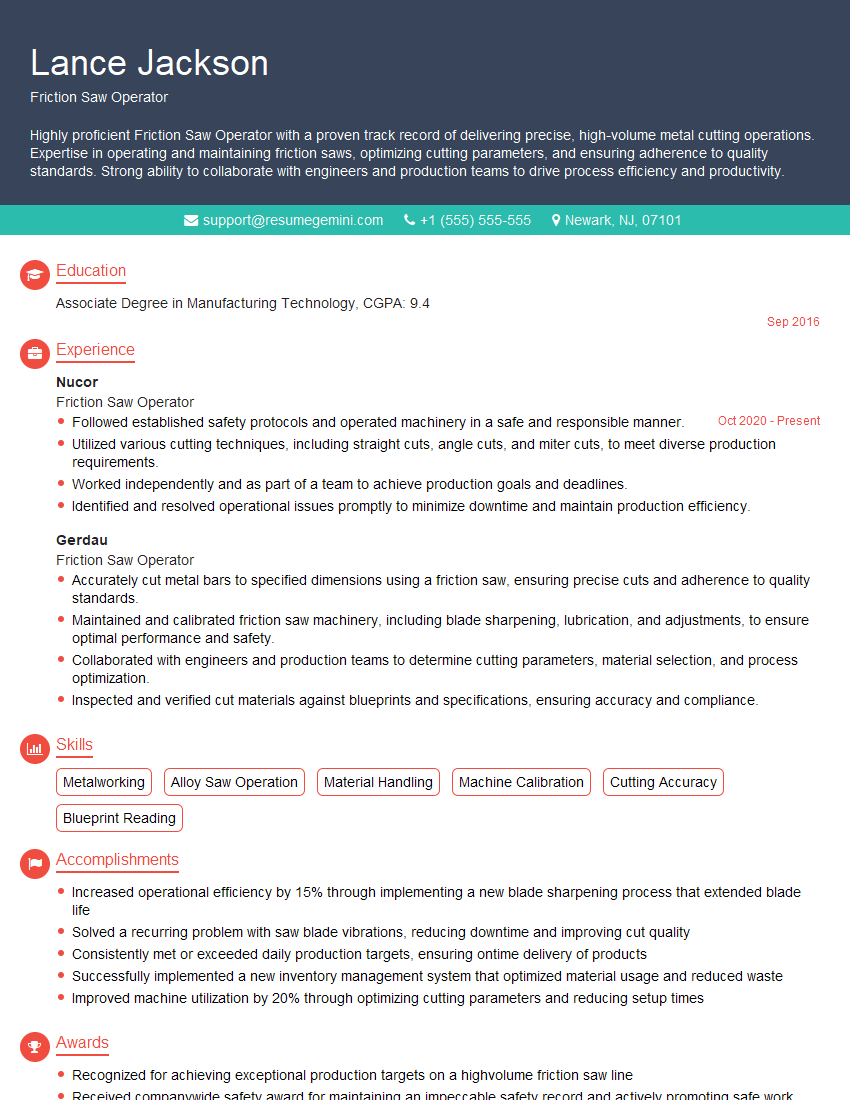

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Friction Saw Operator

1. What are the different types of friction saws and their applications?

Friction saws are categorized into three main types:

- Vertical Friction Saws: Designed for precise straight cuts, ideal for cutting non-ferrous metals like aluminum, brass, and copper.

- Horizontal Friction Saws: Suitable for cutting large-diameter materials and ferrous metals, allowing for horizontal feed and automatic blade stroke.

- Portable Friction Saws: Compact and versatile, used for cutting pipes, beams, and other bulky materials at various job sites.

2. Explain the importance of blade selection for friction saws and how do you determine the appropriate blade for different materials?

Blade Material

- High-speed steel (HSS) blades: Durable and economical, suitable for cutting mild steel and non-ferrous metals.

- Carbide-tipped blades: Increased hardness and wear resistance, ideal for cutting harder materials like stainless steel and titanium.

Blade Geometry

- Tooth pitch: Smaller pitch for finer cuts, larger pitch for faster cutting.

- Tooth profile: Various profiles (e.g., raker, skip tooth) for different materials and cutting conditions.

3. Describe the safety procedures and precautions when operating a friction saw?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Ensure the machine is properly grounded and the blade guard is in place.

- Check the blade for any damage or cracks before operation.

- Secure the workpiece firmly to prevent movement during cutting.

- Never reach over or around the rotating blade.

4. How do you maintain and troubleshoot friction saws for optimal performance?

Maintenance

- Regular blade sharpening to maintain sharpness.

- Cleaning and lubrication of moving parts.

- Checking and adjusting blade tension.

Troubleshooting

- Excessive vibration: Check blade tension, balance, or workpiece securing.

- Poor cut quality: Inspect blade sharpness, tooth profile, or feed rate.

- Blade breakage: Examine blade condition, tension, and material compatibility.

5. What factors influence the cutting speed and feed rate of a friction saw?

- Blade material and hardness.

- Material being cut (e.g., thickness, hardness).

- Blade speed and feed rate settings.

- Desired cut quality and accuracy.

6. How do you calibrate and adjust a friction saw for precise cutting?

- Ensure the blade is aligned perpendicular to the table.

- Adjust the miter gauge for accurate angle cuts.

- Set the blade height to match the workpiece thickness.

- Calibrate the feed rate and blade speed based on the material being cut.

7. Explain how you handle different types of materials in a friction saw operation?

- Ferrous metals: Use carbide-tipped blades with low feed rates.

- Non-ferrous metals: Use HSS blades with higher feed rates.

- Plastics: High feed rates with fine-toothed blades to minimize melting.

- Composites: Specialized blades designed for composite materials.

8. What techniques do you employ to achieve burr-free and clean cuts on a friction saw?

- Use sharp and properly tensioned blades.

- Select the appropriate feed rate and blade speed.

- Secure the workpiece firmly to prevent vibration.

- Apply coolant or lubricant to reduce friction and burr formation.

9. Describe your experience with using specialized friction saw attachments, such as coolant systems or dust collectors?

- Coolant systems: Explained the benefits of using coolant, such as reducing blade wear, improving cut quality, and minimizing burr formation.

- Dust collectors: Highlighted the importance of maintaining a clean work environment, preventing dust inhalation, and minimizing fire hazards.

10. What qualities or skills do you possess that make you a suitable candidate for this Friction Saw Operator position?

- Proven experience in operating and maintaining friction saws.

- Strong understanding of cutting parameters, materials, and safety procedures.

- Attention to detail and commitment to precision cutting.

- Ability to work independently and as part of a team.

- Excellent communication and problem-solving skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Friction Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Friction Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Friction Saw Operator is entrusted with the operation and maintenance of friction saws to cut a range of materials, including metal, plastic, and wood. This role also involves adhering to safety protocols, ensuring smooth production processes, and delivering optimal outputs.

1. Operation of Friction Saws

Execute sawing operations using friction saws, utilizing specialized techniques to achieve precise and clean cuts.

- Interpret technical drawings and specifications to determine cut parameters.

- Set up and calibrate friction saws to ensure accurate and efficient cutting.

- Operate saws safely, adhering to established safety procedures and guidelines.

2. Material Handling and Preparation

Prepare materials for cutting by measuring and marking them according to specified requirements.

- Load and secure materials onto the friction saw work table.

- Ensure that materials are properly aligned and secured for precise cutting.

- Monitor material flow and adjust cutting parameters as needed to maintain optimal production rates.

3. Quality Assurance and Inspection

Inspect cut materials to ensure they meet specified tolerances and quality standards.

- Use measuring tools and gauges to verify dimensional accuracy and surface finish.

- Identify and rectify any deviations from specifications to maintain product quality.

- Provide feedback to supervisors regarding quality control and any potential process improvements.

4. Troubleshooting and Maintenance

Perform routine maintenance and troubleshooting tasks to ensure the smooth operation of friction saws.

- Conduct regular maintenance checks, cleaning and lubricating moving parts.

- Troubleshoot and resolve operational issues, ensuring minimal downtime.

- Report any significant maintenance needs or potential safety hazards to supervisors.

Interview Tips

To enhance your preparation for the Friction Saw Operator interview, consider the following tips:

1. Research the Company and Job Description

Thoroughly research the company, its values, and the specific requirements of the Friction Saw Operator role. This will demonstrate your genuine interest and alignment with the organization.

2. Practice Common Interview Questions

Anticipate and prepare answers to common interview questions, such as “Tell us about your experience with friction saws” and “What are the safety measures you follow when operating machinery?”.

3. Showcase Your Skills and Experience

Highlight your relevant skills and experience in friction saw operation, material handling, quality control, and troubleshooting. Provide specific examples to demonstrate your capabilities.

4. Emphasize Safety and Accuracy

Emphasize your commitment to safety protocols and your ability to deliver precise and accurate cuts. Share examples of how you have implemented safety measures and maintained high-quality standards in previous roles.

5. Prepare Questions for the Interviewer

Prepare thoughtful questions to ask the interviewer. This shows your engagement and interest in the role and the company. For example, you could inquire about the company’s production targets or the opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Friction Saw Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.