Feeling lost in a sea of interview questions? Landed that dream interview for Frit Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Frit Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

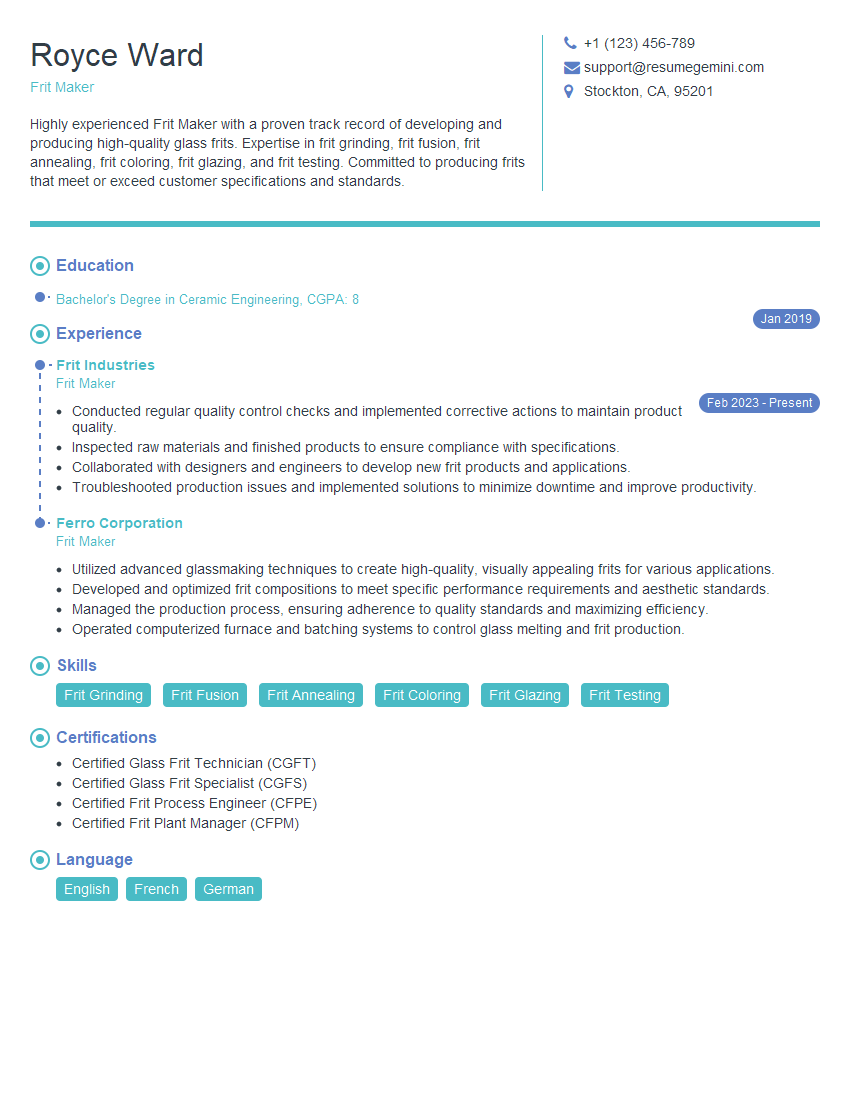

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Frit Maker

1. What are the key responsibilities of a Frit Maker?

As a Frit Maker, I would be responsible for the following key tasks:

- Operate and maintain frit furnaces to produce high-quality frit for glass production.

- Monitor and control furnace temperature, raw material composition, and process parameters to ensure optimal frit production.

- Perform quality control tests on frit samples to verify adherence to specifications and customer requirements.

- Troubleshoot and resolve issues related to furnace operation, material composition, and product quality.

- Maintain a clean and organized work area, ensuring adherence to safety protocols and industry standards.

2. Describe the different types of frit furnaces and their applications

Electric Furnaces:

- Precise temperature control and energy efficiency.

- Used for producing high-quality specialty frits.

Gas-Fired Furnaces:

- High heat output and rapid heating rates.

- Suitable for large-scale production of standard frits.

Oxy-Fuel Furnaces:

- Combination of oxygen and fuel provides high temperatures.

- Used for melting refractory materials and producing frits with unique properties.

3. Explain the process of frit production

The frit production process typically involves the following steps:

- Raw materials (e.g., silica, fluxes, pigments) are weighed and mixed according to the desired frit composition.

- The mixture is charged into the furnace and heated to a high temperature (1200-1600°C), melting the raw materials and forming a molten frit.

- The molten frit is quenched rapidly by pouring it into water, shattering it into small glass fragments.

- The frit fragments are dried and ground into a fine powder, ready for use in glass production.

4. How do you ensure the quality of the produced frit?

To ensure the quality of the produced frit, I would adhere to the following measures:

- Regularly calibrate and maintain furnace equipment to ensure accurate temperature control.

- Perform chemical analysis and physical tests on frit samples to verify compliance with specifications.

- Monitor the raw material quality and adjust the frit composition as needed to achieve optimal properties.

- Document all production parameters and quality control results to maintain traceability and consistency.

5. What safety precautions should be taken when operating a frit furnace?

When operating a frit furnace, I would prioritize the following safety precautions:

- Wear appropriate personal protective equipment (PPE) including heat-resistant clothing, gloves, and eye protection.

- Ensure proper ventilation to prevent exposure to fumes and gases.

- Handle molten frit with extreme care using appropriate tools and protective gear.

- Follow established operating procedures and lockout/tagout protocols to prevent accidents.

- Be aware of the potential hazards associated with high temperatures and electrical equipment.

6. Explain the importance of maintaining accurate records in frit production

Maintaining accurate records in frit production is crucial for several reasons:

- Traceability: Records provide a detailed history of the production process, enabling the identification of any issues or deviations.

- Quality assurance: Records document quality control tests and results, verifying compliance with specifications and ensuring product consistency.

- Process optimization: By analyzing production data, manufacturers can identify areas for improvement and optimize the frit production process.

- Regulatory compliance: Records provide evidence of adherence to industry standards and regulations, ensuring transparency and accountability.

7. What are the different applications of frit in glass production?

Frit finds diverse applications in glass production, including:

- Glazes and enamels: Frit is used to create colorful and durable glazes for ceramics, tiles, and glass objects.

- Colored glass: Frit is added to molten glass to produce colored glass products such as bottles, windows, and art glass.

- Glass-ceramics: Frit is used in the production of glass-ceramics, which combine the properties of glass and ceramics.

- Vitreous enamels: Frit is utilized in the manufacturing of vitreous enamels, which provide a protective and decorative coating on metal surfaces.

8. How do you handle and store frit materials safely?

To ensure safe handling and storage of frit materials, I would follow these practices:

- Wear respiratory protection when handling dusty frit powders.

- Store frit materials in airtight containers to prevent moisture absorption.

- Keep frit away from incompatible materials such as acids and bases.

- Label and identify all frit containers clearly to avoid confusion.

- Train staff on proper handling and storage procedures.

9. What are the common challenges faced in frit production and how do you overcome them?

Common challenges in frit production include:

- Temperature control: Maintaining precise furnace temperatures is crucial to ensure consistent frit quality.

- Raw material variability: Fluctuations in raw material quality can affect the final frit properties.

- Equipment maintenance: Regular maintenance of furnaces and other equipment is essential to prevent downtime and ensure safety.

To overcome these challenges, I would:

- Utilize calibrated and well-maintained equipment.

- Establish strict quality control measures for raw materials.

- Implement preventive maintenance schedules and train staff on proper equipment operation.

10. How do you stay updated with the latest advancements in frit production technology?

To stay abreast of the latest advancements in frit production technology, I would:

- Attend industry conferences and exhibitions.

- Read technical journals and industry publications.

- Network with other frit makers and experts in the field.

- Explore research and development initiatives related to frit production.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Frit Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Frit Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Frit makers are responsible for the production of frit, a type of glass used in a variety of industries, including ceramics, glassmaking, and construction. They operate furnaces and other equipment to melt and shape frit, ensuring that it meets the required specifications. Key responsibilities include:

1. Furnace Operation

Frit makers operate and maintain furnaces used to melt raw materials into frit. They monitor temperature and other furnace conditions, making adjustments as needed to ensure the proper melting process. They also perform regular maintenance and repairs on furnaces to keep them in good working order.

- Monitor furnace temperature and other conditions to ensure proper melting.

- Adjust furnace settings and make repairs as needed to maintain optimal operating conditions.

2. Frit Production

Frit makers are responsible for producing frit according to specific formulations and specifications. They weigh and mix raw materials, such as silica sand, soda ash, and borax, and then melt them in the furnace. They use various techniques to shape the molten frit, such as pouring it into molds or extruding it into rods or sheets. They also perform quality control tests on the frit to ensure that it meets the required standards.

- Weigh and mix raw materials according to formulations.

- Operate furnaces to melt raw materials and produce frit.

- Shape molten frit using molds or other techniques.

- Perform quality control tests on frit to ensure it meets specifications.

3. Equipment Maintenance

Frit makers are also responsible for maintaining the equipment used in the production process. They perform regular inspections and cleanings, and make repairs as needed. They also work with other maintenance personnel to ensure that the equipment is always in good working order.

- Inspect and clean equipment regularly.

- Make repairs to equipment as needed.

- Work with maintenance personnel to ensure equipment is in good working order.

4. Safety and Compliance

Frit makers must adhere to all safety regulations and guidelines. They wear personal protective equipment (PPE) and follow all safety procedures to minimize the risk of accidents or injuries. They also ensure that the work area is clean and free of hazards.

- Wear personal protective equipment (PPE) and follow all safety procedures.

- Ensure that the work area is clean and free of hazards.

Interview Tips

To ace your interview for a frit maker position, it is important to be well-prepared and to demonstrate your knowledge and skills in the field. Here are some tips to help you succeed:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job. You can research the company’s website, LinkedIn page, and other online sources.

- Visit the company’s website and LinkedIn page.

- Read articles and news about the company.

- Talk to people in your network who work for the company.

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely. You can also prepare for questions specific to the frit making industry, such as “What is your experience with furnace operation?” or “How do you ensure the quality of your frit?”

- Prepare answers to common interview questions.

- Practice answering questions specific to the frit making industry.

- Use the STAR method to answer questions: Situation, Task, Action, Result.

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the frit maker position. For example, if you have experience operating furnaces or producing frit, be sure to mention this. You can also highlight your knowledge of the glass and ceramics industry, as well as your safety and compliance experience.

- Highlight your skills and experience in your resume and cover letter.

- Discuss your skills and experience in detail during the interview.

- Provide specific examples of your accomplishments.

4. Be Enthusiastic and Professional

It is important to be enthusiastic and professional throughout the interview process. This means dressing appropriately, arriving on time for your interview, and maintaining eye contact with the interviewer. You should also be polite and respectful, and avoid interrupting the interviewer.

- Dress appropriately for the interview.

- Arrive on time for your interview.

- Maintain eye contact with the interviewer.

- Be polite and respectful.

- Avoid interrupting the interviewer.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the opportunity and that you are taking the interview seriously. You can also ask questions about the company’s culture, values, and goals. Asking questions also gives you an opportunity to learn more about the position and the company, which can help you make an informed decision about whether or not to accept the job if you are offered it.

- Prepare questions to ask the interviewer at the end of the interview.

- Questions should be specific and thoughtful.

- Asking questions shows that you are interested in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Frit Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.