Feeling lost in a sea of interview questions? Landed that dream interview for Fuel Cell Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fuel Cell Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

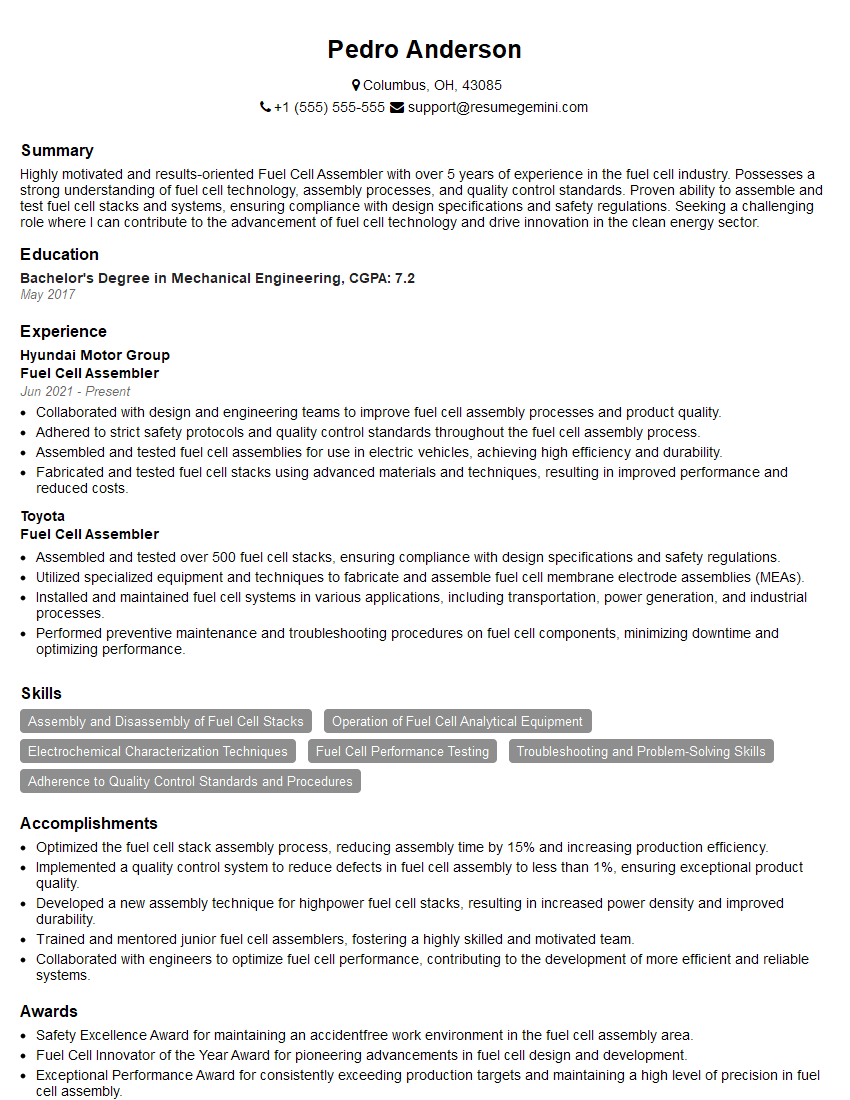

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fuel Cell Assembler

1. What are the key steps involved in assembling a fuel cell?

In assembling a fuel cell, the key steps are:

- Preparing the components, including electrodes, membranes, and gaskets.

- Assembling the cell stack by stacking the components in a specific order.

- Applying pressure and heat to the stack to form a seal and activate the cell.

- Testing the cell to ensure proper performance.

2. What are the different types of fuel cells and their applications?

Types of fuel cells

- Proton exchange membrane fuel cells (PEMFCs): Used in vehicles, portable devices, and stationary power applications.

- Solid oxide fuel cells (SOFCs): Used in stationary power applications and high-temperature industrial processes.

- Alkaline fuel cells (AFCs): Used in space applications and backup power systems.

- Direct methanol fuel cells (DMFCs): Used in portable devices and small vehicles.

Applications of fuel cells

- Transportation: Powering vehicles such as cars, buses, and forklifts.

- Stationary power: Providing electricity for homes, businesses, and industries.

- Portable power: Supplying electricity for laptops, phones, and other devices.

- Backup power: Providing emergency power during grid outages.

3. What are the safety precautions that must be taken when working with fuel cells?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Work in a well-ventilated area to avoid exposure to harmful gases.

- Handle fuel and oxidant safely, following proper storage and handling procedures.

- Be aware of the potential for electrical hazards and take precautions to avoid shocks.

- Follow established safety protocols and procedures.

4. What are the common troubleshooting steps for fuel cell assembly issues?

- Check for leaks in the fuel and oxidant supply lines.

- Inspect the cell stack for proper alignment and connections.

- Measure the voltage and current output of the cell to identify any performance issues.

- Check the temperature and humidity of the operating environment.

- Analyze the cell’s electrochemical impedance to identify any potential problems.

5. What are the latest advancements in fuel cell technology?

- Development of high-performance and durable catalysts.

- Improved membrane materials for increased efficiency and lifespan.

- Miniaturization of fuel cells for portable applications.

- Exploration of alternative fuels, such as hydrogen-rich fuels and biofuels.

- Integration of fuel cells with other energy technologies, such as solar and wind power.

6. What are the advantages and disadvantages of using fuel cells?

Advantages

- Clean and efficient energy source with low emissions.

- High power density and scalability.

- Long lifespan and reliability.

- Quiet operation.

Disadvantages

- High upfront cost.

- Limited availability of hydrogen fuel infrastructure.

- Sensitivity to impurities in the fuel and oxidant.

- Water management challenges.

7. What are the quality control measures implemented in fuel cell assembly?

- Visual inspection of components and assemblies for defects.

- Electrical testing to verify proper connectivity and performance.

- Pressure and leak testing to ensure the stack’s integrity.

- Environmental testing to simulate real-world operating conditions.

- Documentation and traceability of all assembly steps.

8. What are the different materials used in fuel cell components and their properties?

- Electrodes: Platinum, carbon, or other conductive materials with high electrocatalytic activity.

- Membranes: Proton exchange membranes (PEMs) or solid oxide membranes (SOMs) for ion conduction.

- Gaskets: Fluorinated polymers or elastomers for sealing and preventing leakage.

- Bipolar plates: Graphite, metal, or composite materials for current collection and gas distribution.

- End plates: Stainless steel or composite materials for structural support and sealing.

9. How do you stay updated with the latest trends and developments in fuel cell technology?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and discussion groups.

- Networking with other professionals in the field.

- Engaging in research and development activities.

10. What is your experience with fuel cell testing and performance evaluation?

- Conducted performance tests on fuel cells to measure power output, efficiency, and durability.

- Analyzed test data and identified areas for improvement.

- Developed and implemented testing protocols to ensure consistent and reliable results.

- Collaborated with engineers and scientists to optimize fuel cell design and performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fuel Cell Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fuel Cell Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fuel Cell Assemblers play a vital role in manufacturing and servicing fuel cells, which are a critical component in many renewable energy and power generation systems.

1. Assembly and Inspection

Assembling fuel cell components, like bipolar plates, membranes, and catalyst layers, following strict quality standards.

- Inspecting assembled fuel cells for defects or inconsistencies using specialized tools and techniques.

- Ensuring that all components are correctly aligned and securely fastened.

2. Testing and Troubleshooting

Conducting performance tests on assembled fuel cells to evaluate efficiency, durability, and other critical parameters.

- Troubleshoot any issues that arise during testing and implement corrective actions.

- Analyze test results and provide feedback to improve the manufacturing process.

3. Maintenance and Repair

Performing scheduled maintenance tasks to ensure optimal performance of fuel cell systems.

- Replacing worn or damaged components, such as gaskets, seals, and electrodes.

- Cleaning and inspecting fuel cells to prevent malfunctions or breakdowns.

4. Process Improvement

Identifying areas for process improvement within the fuel cell assembly line.

- Collaborating with engineers and technicians to develop and implement solutions.

- Keeping up-to-date with the latest advancements in fuel cell technology.

Interview Tips

Preparing thoroughly for your Fuel Cell Assembler interview will increase your chances of success. Here are some tips to help you ace it:

1. Research the Company and Role

Learn about the company’s mission, values, and the specific requirements of the Fuel Cell Assembler role.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on the latest fuel cell technologies.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in fuel cell assembly, inspection, and testing.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Prepare examples of projects or situations where you demonstrated your problem-solving abilities.

3. Demonstrate Your Knowledge

Show the interviewer that you have a strong understanding of fuel cell technology and its applications.

- Explain the basic principles of fuel cell operation.

- Describe the different types of fuel cells and their advantages and disadvantages.

4. Be Enthusiastic and Professional

Convey your passion for fuel cell technology and your desire to contribute to the company’s success.

- Dress professionally and arrive on time for your interview.

- Be polite and respectful to everyone you meet.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fuel Cell Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!