Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fuel Cell Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fuel Cell Engineer so you can tailor your answers to impress potential employers.

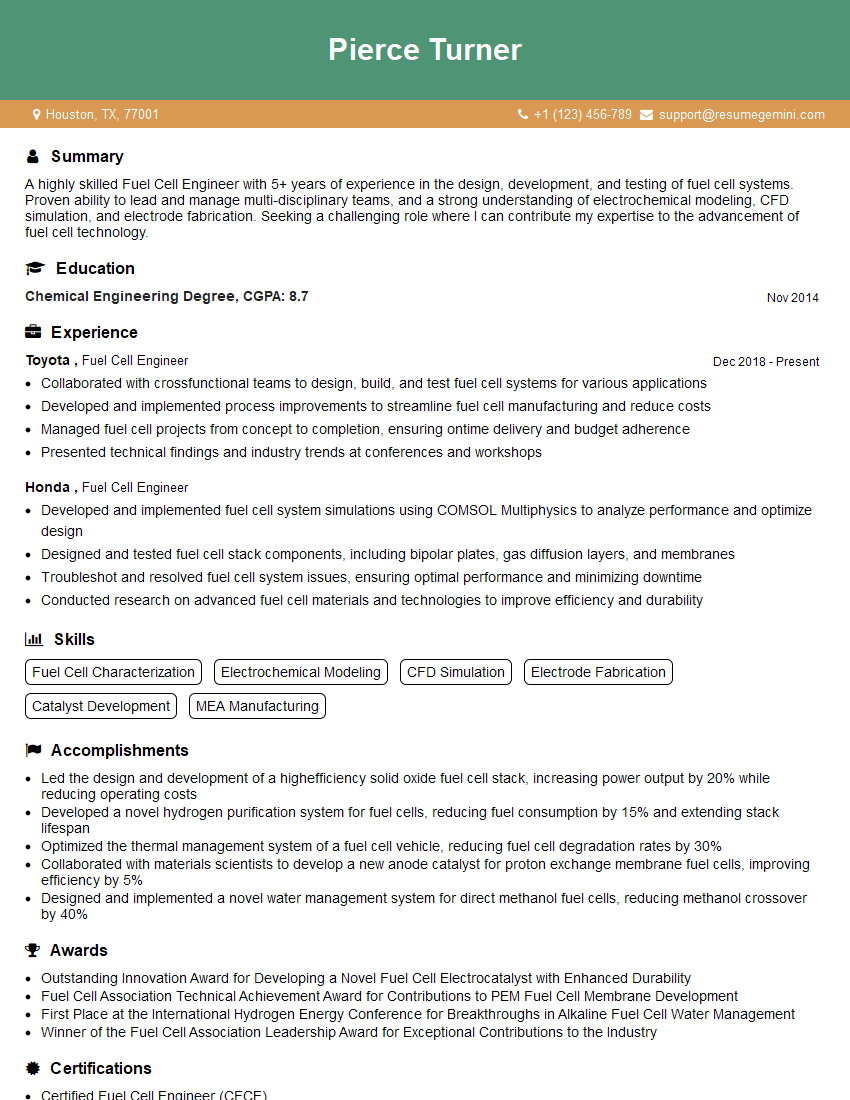

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fuel Cell Engineer

1. Explain the basic working principle of a Proton Exchange Membrane Fuel Cell (PEMFC)?

- A Proton Exchange Membrane Fuel Cell (PEMFC) is an electrochemical device that converts chemical energy from a fuel source into electrical energy.

- In a PEMFC, hydrogen fuel is supplied to the anode, while oxygen is supplied to the cathode.

- A proton exchange membrane (PEM) separates the anode and cathode, allowing protons to pass through but blocking electrons.

- At the anode, hydrogen molecules are split into protons and electrons. The protons pass through the PEM, while the electrons are collected by an external circuit.

- At the cathode, oxygen molecules are combined with protons and electrons to form water.

- The overall reaction produces electricity, heat, and water.

2. What are the key performance parameters of a PEMFC?

Efficiency

- PEMFCs typically have an efficiency of 50-60%.

Power density

- PEMFCs have a high power density, typically in the range of 1-2 kW/L.

Durability

- PEMFCs have a relatively long lifespan, typically in the range of 5,000-10,000 hours.

Cost

- The cost of PEMFCs is still relatively high, but it is expected to come down as the technology matures.

3. What are the different types of PEMFCs?

- There are several different types of PEMFCs, including:

- Unreinforced PEMFCs: These PEMFCs do not contain any reinforcement material in the membrane.

- Reinforced PEMFCs: These PEMFCs contain a reinforcement material, such as a polymer or a metal, in the membrane.

- Direct methanol fuel cells (DMFCs): These PEMFCs use methanol as a fuel source instead of hydrogen.

- Solid oxide fuel cells (SOFCs): These PEMFCs use a solid oxide electrolyte instead of a polymer membrane.

4. What are the advantages and disadvantages of PEMFCs?

Advantages

- High efficiency

- High power density

- Long lifespan

- Low emissions

- Compact and lightweight

Disadvantages

- High cost

- Sensitivity to impurities in the fuel

- Limited operating temperature range

5. What are the applications of PEMFCs?

- PEMFCs are used in a variety of applications, including:

- Transportation: PEMFCs are used to power electric vehicles, such as cars, buses, and trains.

- Stationary power: PEMFCs are used to provide backup power for critical facilities, such as hospitals and data centers.

- Portable power: PEMFCs are used to power portable devices, such as laptops and cell phones.

6. What challenges need to be overcome for PEMFCs to become widely adopted?

- The high cost of PEMFCs

- The sensitivity of PEMFCs to impurities in the fuel

- The limited operating temperature range of PEMFCs

- The need for a hydrogen infrastructure

7. Explain the role of a catalyst in a PEMFC

- A catalyst is a substance that increases the rate of a chemical reaction without being consumed in the reaction.

- In a PEMFC, the catalyst is typically a platinum-based material.

- The catalyst helps to split hydrogen molecules into protons and electrons at the anode, and to combine oxygen molecules with protons and electrons to form water at the cathode.

8. Describe the different types of bipolar plates used in PEMFCs?

- Bipolar plates are used to separate the individual cells in a PEMFC stack.

- Bipolar plates are typically made of a metal, such as stainless steel or graphite.

- There are two main types of bipolar plates: serpentine bipolar plates and parallel bipolar plates.

- Serpentine bipolar plates have a serpentine-shaped flow channel pattern, while parallel bipolar plates have a parallel flow channel pattern.

9. What is the purpose of a gas diffusion layer in a PEMFC?

- A gas diffusion layer (GDL) is a porous material that is located between the catalyst layer and the bipolar plate in a PEMFC.

- The GDL allows gases to diffuse to and from the catalyst layer.

- The GDL also helps to remove water from the catalyst layer.

10. Explain the different methods used to control the temperature of a PEMFC?

- There are several different methods used to control the temperature of a PEMFC, including:

- Air cooling: Air is passed over the PEMFC to remove heat.

- Liquid cooling: A liquid, such as water or glycol, is passed through the PEMFC to remove heat.

- Passive cooling: The PEMFC is designed to dissipate heat through conduction and radiation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fuel Cell Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fuel Cell Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fuel Cell Engineers play a crucial role in the development and deployment of clean energy technologies, primarily involving fuel cell systems for various applications. Their core responsibilities encompass:

1. Fuel Cell Design and Development

Collaborating in the design, simulation, and optimization of fuel cell systems, including cell components, stacks, and auxiliary systems, to enhance performance and efficiency.

2. Materials and Process Engineering

Evaluating and selecting suitable materials for fuel cell components based on their chemical, electrochemical, and mechanical properties, optimizing fabrication processes to ensure component reliability and durability.

3. System Integration and Testing

Integrating fuel cell systems into larger systems, such as transportation vehicles, portable power units, and stationary power plants, conducting comprehensive testing and evaluation to verify performance and safety.

4. Troubleshooting and Failure Analysis

Identifying and resolving technical issues arising during fuel cell system development and deployment, analyzing failure modes to determine root causes and implement corrective measures.

Interview Tips

Preparing thoroughly for a Fuel Cell Engineer interview is essential to showcase your technical expertise and enthusiasm for this field. Here are some tips to help you ace the interview:

1. Research the Company and Role

Thoroughly research the company’s mission, values, and the specific role you are applying for. Understanding the company’s goals and the expectations for the position will help you tailor your answers effectively.

2. Highlight Your Technical Skills

Emphasize your knowledge of fuel cell science, materials engineering, and system integration. Provide specific examples of projects where you applied these skills and achieved tangible results.

3. Showcase Your Problem-Solving Abilities

Fuel Cell Engineers are often faced with complex technical challenges. Highlight your ability to identify problems, analyze data, and develop innovative solutions. Use the STAR method (Situation, Task, Action, Result) to structure your answers and demonstrate your problem-solving process.

4. Prepare for Technical Questions

Anticipate technical questions related to fuel cell design, materials selection, system integration, and troubleshooting. Review fundamental concepts and prepare clear and concise answers that demonstrate your understanding.

5. Ask Informed Questions

Asking insightful questions at the end of the interview shows your engagement and interest in the role. Prepare questions about the company’s current projects, future plans, and the specific challenges the team is facing. This demonstrates your genuine curiosity and eagerness to contribute.

Next Step:

Now that you’re armed with the knowledge of Fuel Cell Engineer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Fuel Cell Engineer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini