Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fuel Handler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

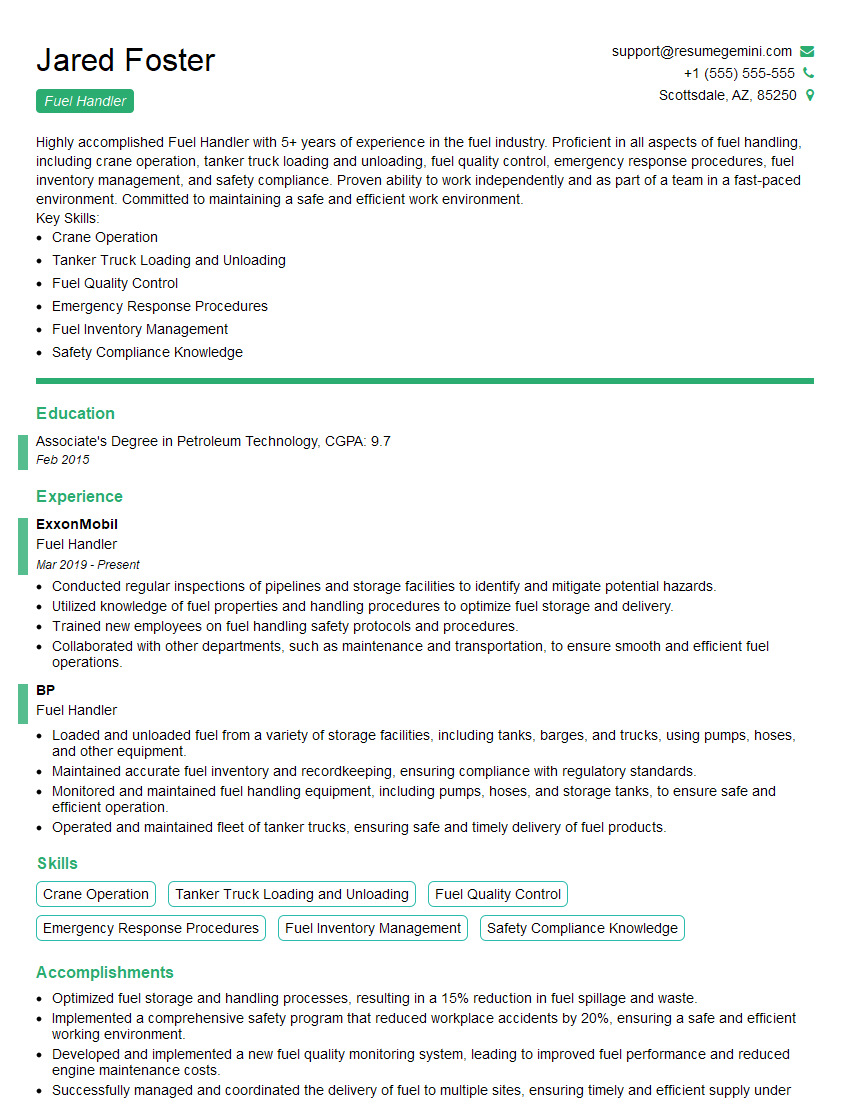

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fuel Handler

1. How do you ensure the quality of fuel before it is distributed?

To ensure the quality of fuel before distribution, I follow these steps:

- Regular Sampling and Testing: I collect samples from storage tanks and distribution lines to test for properties such as density, viscosity, and sulfur content.

- Adherence to Specifications: I compare the test results to established specifications and industry standards to ensure that the fuel meets the required quality parameters.

- Visual Inspection: I visually inspect the fuel for any signs of contamination, discoloration, or unusual behavior.

- Maintenance of Equipment: I regularly maintain and calibrate testing equipment to ensure accurate and reliable results.

2. What are the safety procedures you follow when handling and distributing fuel?

PPE and Safety Gear:

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and protective clothing.

- Use designated safety equipment, such as spill containment kits and fire extinguishers.

- Maintain a clean and organized work area.

Hazard Identification and Risk Assessment:

- Identify potential hazards associated with fuel handling, such as leaks, spills, and fires.

- Assess risks and implement control measures to mitigate them.

- Stay informed about emergency protocols and evacuation procedures.

3. How do you maintain accurate records of fuel inventory and distribution?

I maintain accurate fuel inventory and distribution records through:

- Electronic Tracking System: I use a computerized system to track fuel receipts, withdrawals, and inventory levels.

- Physical Audits: I conduct regular physical audits of fuel storage tanks to verify inventory levels and reconcile them with electronic records.

- Documentation: I maintain a detailed log of all fuel transactions, including dates, quantities, and delivery information.

- Communication and Coordination: I communicate regularly with suppliers, customers, and internal departments to ensure accurate and timely updates of inventory records.

4. Describe your experience in handling and troubleshooting fuel-related emergencies.

During an emergency involving fuel, I remain calm and follow these steps:

- Identify and Control the Source: Quickly locate the source of the leak or spill and take immediate action to contain it.

- Notify Authorities: Report the incident to the appropriate authorities and emergency responders.

- Evacuate Personnel: Ensure the safety of personnel by evacuating the affected area and establishing a safe perimeter.

- Implement Mitigation Measures: Use available resources, such as spill kits, containment booms, and fire extinguishers, to mitigate the situation.

5. What are your knowledge of different types of fuel and their properties?

I have a comprehensive understanding of different types of fuel, including:

- Gasoline: Highly flammable, used in vehicles with spark-ignition engines.

- Diesel: Less flammable than gasoline, used in compression-ignition engines.

- Biodiesel: Renewable fuel made from plant or animal sources, similar properties to diesel.

- Aviation Fuel: Specifically designed for aircraft engines, with high purity and specific performance requirements.

- Heating Oil: Used for heating homes and buildings, characterized by low volatility and high viscosity.

6. Explain the principles of fuel combustion and how you optimize efficiency.

Fuel combustion involves a chemical reaction between fuel and oxygen, releasing heat energy. To optimize combustion efficiency, I:

- Ensure Proper Air-Fuel Ratio: Adjust fuel flow and air intake to achieve the ideal ratio for complete combustion.

- Maintain Combustion Chamber Temperature: Monitor and regulate the temperature to optimize the combustion process.

- Use High-Quality Fuel: Utilize fuel with appropriate specifications for the combustion system.

- Regular Equipment Maintenance: Keep combustion equipment clean and well-maintained to prevent efficiency losses.

7. Describe your experience in working with fuel additives and their applications.

I have experience in handling and using fuel additives for various purposes:

- Detergents: Help clean and prevent the formation of deposits in fuel systems.

- Anti-knock Agents: Improve fuel octane rating and reduce engine knocking.

- Lubricity Improvers: Enhance fuel lubricity to reduce wear on fuel system components.

- Corrosion Inhibitors: Protect fuel systems from corrosion, especially in the presence of water.

8. Explain how you ensure compliance with environmental regulations related to fuel handling.

To comply with environmental regulations, I:

- Proper Storage and Handling: Adhere to guidelines for storing and handling fuel to prevent spills and leaks.

- Spill Prevention and Control: Implement measures to contain and clean up any potential spills.

- Waste Management: Dispose of used fuel, filters, and other materials in accordance with environmental regulations.

- Emissions Control: Monitor and control emissions from fuel combustion and storage operations.

9. Describe your understanding of fuel quality standards and how you monitor compliance.

I am familiar with various fuel quality standards, such as ASTM, ISO, and industry specifications. To monitor compliance:

- Regular Testing: Conduct routine testing to ensure that fuel meets the required specifications.

- Supplier Certification: Verify that fuel suppliers meet industry standards and provide quality fuel.

- Maintaining Records: Document all test results and quality control measures for auditing and traceability purposes.

10. Explain the role of technology in fuel handling and your experience with relevant systems.

Technology plays a vital role in fuel handling, and I have experience with various systems:

- Fuel Management Software: Track inventory, monitor consumption, and manage fuel deliveries.

- Automated Dispensing Systems: Control and monitor fuel dispensing operations, reducing errors and improving efficiency.

- Remote Monitoring Systems: Monitor fuel levels, detect leaks, and provide real-time data for analysis and optimization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fuel Handler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fuel Handler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fuel Handlers are responsible for the safe and efficient handling of fuel products, including gasoline, diesel, and jet fuel. They work in a variety of settings, including gas stations, airports, and fuel depots.

1. Fuel Handling

Fuel Handlers operate and maintain fuel storage and dispensing equipment. They ensure that fuel is stored and dispensed safely and in accordance with regulations. They also monitor fuel levels and report any discrepancies.

- Operate and maintain fuel storage tanks, pumps, and other equipment

- Dispense fuel to vehicles and aircraft

- Monitor fuel levels and report discrepancies

2. Safety and Compliance

Fuel Handlers are responsible for ensuring the safety of themselves and others in the workplace. They must follow all safety protocols and regulations, and they must be able to identify and mitigate potential hazards.

- Follow all safety protocols and regulations

- Identify and mitigate potential hazards

- Respond to emergencies

3. Customer Service

Fuel Handlers often interact with customers, so they must be able to provide excellent customer service. They must be able to answer questions, resolve complaints, and build relationships with customers.

- Provide excellent customer service

- Answer questions and resolve complaints

- Build relationships with customers

4. Physical Requirements

Fuel Handlers must be able to perform a variety of physical tasks, including lifting heavy objects, climbing ladders, and working in confined spaces. They must also be able to work in all types of weather conditions.

- Lift heavy objects

- Climb ladders

- Work in confined spaces

- Work in all types of weather conditions

Interview Tips

Preparing for a Fuel Handler interview can help you increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the Company and Position

Take some time to learn about the company you’re applying to and the specific position you’re applying for. This will help you understand the company’s culture and the requirements of the job. You can find this information on the company’s website, Glassdoor, or other online resources.

- Visit the company’s website

- Read Glassdoor reviews

- Talk to people who work at the company

2. Practice Answering Common Interview Questions

There are a few common interview questions that you’re likely to be asked in a Fuel Handler interview. It’s a good idea to practice answering these questions before the interview so that you can give confident and concise answers.

- “Tell me about your experience handling fuel.”

- “What are your safety protocols for handling fuel?”

- “How do you provide excellent customer service?”

3. Be Prepared to Talk About Your Physical Abilities

Fuel Handlers must be able to perform a variety of physical tasks, so it’s important to be prepared to talk about your physical abilities in the interview. Be sure to highlight any experience you have with lifting heavy objects, climbing ladders, and working in confined spaces.

- Emphasize your strength and agility

- Describe your experience working in physically demanding environments

- Mention any certifications or training you have in safety procedures

4. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This doesn’t mean you need to wear a suit, but you should wear clean, pressed clothes that are appropriate for the job. You should also avoid wearing anything that is too revealing or distracting.

- Wear clean, pressed clothes

- Avoid wearing anything too revealing or distracting

- Make sure your clothes are appropriate for the job

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fuel Handler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!