Are you gearing up for a career in Fullerette? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Fullerette and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

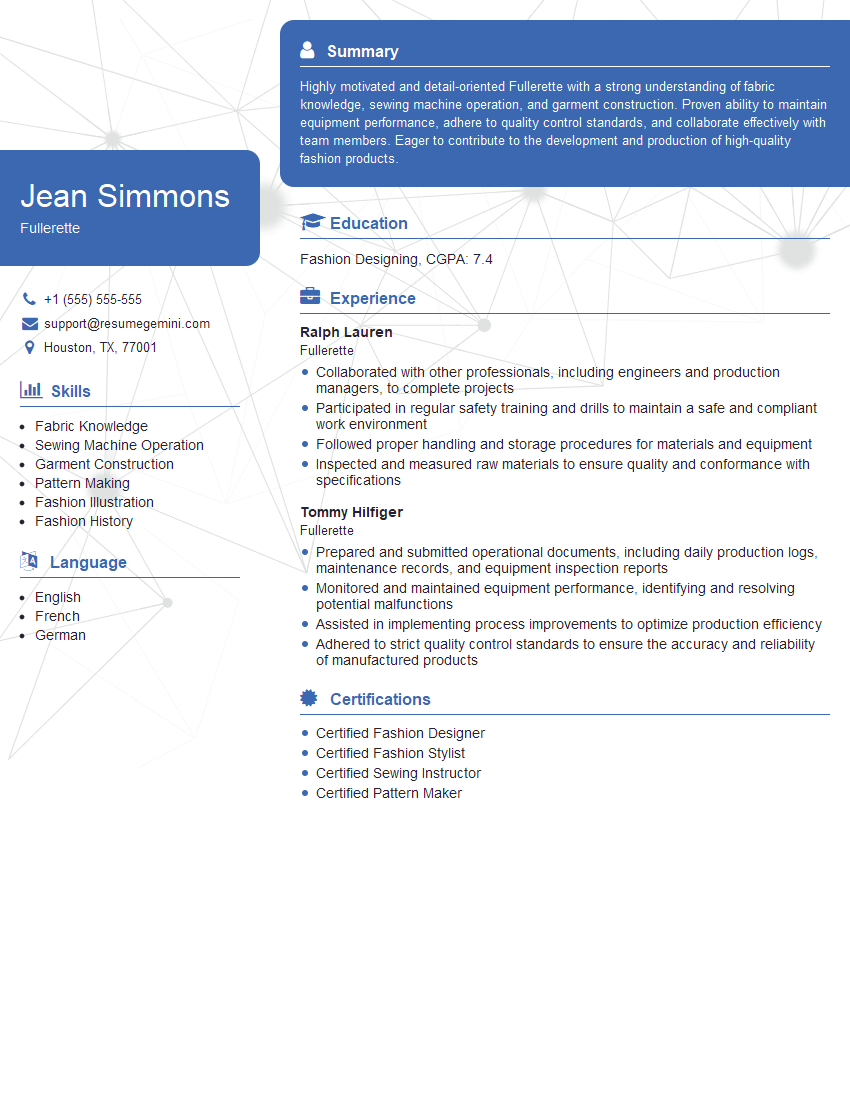

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fullerette

1. How do you define the concept of Fullerette and what are its key characteristics?

Fullerette is a structural element used in the construction of metal buildings. It is a cold-formed steel member that is used to support the roof and wall panels. Fullerettes are typically made from galvanized steel and are available in a variety of sizes and shapes.

- Key characteristics of fullerettes include:

- High strength-to-weight ratio

- Durability

- Corrosion resistance

- Ease of installation

2. Explain the process of designing and fabricating Fullerettes.

Design Considerations

- The design of fullerettes must take into account the following factors:

- The span of the roof or wall

- The weight of the roof or wall panels

- The wind load and snow load in the area where the building is located

Fabrication Process

- Fullerettes are typically fabricated using a cold-forming process. In this process, a sheet of steel is passed through a series of rollers that form the desired shape.

- The fullerette is then cut to the desired length and galvanized to protect it from corrosion.

3. What are the different types of Fullerettes and how are they used in metal buildings?

- There are two main types of fullerettes:

- Solid Fullerettes: These are the most common type of fullerette and are used to support the roof and wall panels.

- Hollow Fullerettes: These are less common and are used in applications where weight is a concern.

4. How do you ensure the quality of Fullerettes and what are the standards that they must meet?

The quality of fullerettes is ensured through a combination of quality control measures and testing.

- Quality Control Measures:

- The raw materials used to manufacture fullerettes are inspected to ensure that they meet the required specifications.

- The fabrication process is monitored to ensure that the fullerettes are manufactured to the correct dimensions and tolerances.

- Testing:

- Fullerettes are tested to ensure that they meet the required strength and durability requirements.

- The tests are conducted in accordance with the relevant industry standards.

5. What are the advantages of using Fullerette in metal buildings?

- Advantages of using fullerettes in metal buildings include:

- High strength-to-weight ratio

- Durability

- Corrosion resistance

- Ease of installation

- Cost-effectiveness

6. What are the challenges associated with the use of Fullerettes and how can they be overcome?

- Challenges associated with the use of fullerettes include:

- Buckling

- Corrosion

- Overcoming Challenges:

- Buckling can be overcome by using thicker fullerettes or by providing additional support.

- Corrosion can be overcome by galvanizing the fullerettes or by using a protective coating.

7. What are the latest trends in the use of Fullerette?

The latest trends in the use of fullerettes include:

- The use of higher-strength steels

- The use of innovative design techniques

- The use of new coatings and finishes

8. What are the future prospects for the use of Fullerette?

The future prospects for the use of fullerettes are promising. The increasing demand for metal buildings and the development of new technologies are expected to drive the growth of the fullerette market in the years to come.

9. What are the key factors to consider when selecting a supplier of Fullerette?

- When selecting a supplier of fullerettes, it is important to consider the following factors:

- The supplier’s experience and reputation

- The quality of the supplier’s products

- The supplier’s customer service

- The supplier’s pricing

10. What questions should I ask a potential supplier of Fullerette?

- Some questions that you should ask a potential supplier of fullerettes include:

- How long have you been in business?

- What is your experience in supplying fullerettes?

- What is the quality of your products?

- What is your customer service like?

- What is your pricing?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fullerette.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fullerette‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fullerette is responsible for the finishing touches on garments and textiles, ensuring that they meet the highest standards of quality and presentation.

1. Fabric Care and Preparation

Ensure that fabrics are clean, pressed, and free of any imperfections.

- Inspect fabrics for any damage or stains.

- Steam or press fabrics to remove wrinkles and creases.

2. Assembly and Finishing

Assemble garments and textiles according to specifications, ensuring that all components are properly aligned and secured.

- Attach buttons, zippers, and other embellishments.

- Sew hems and seams to create a polished look.

3. Quality Control

Inspect finished garments and textiles for any defects or inconsistencies, ensuring that they meet established quality standards.

- Check for loose threads, uneven seams, or any other imperfections.

- Correct any errors or make necessary adjustments.

4. Customer Service

Provide excellent customer service by addressing any concerns or questions regarding the finished products.

- Respond to customer inquiries promptly and professionally.

- Resolve any issues or complaints to ensure customer satisfaction.

Interview Tips

To ace an interview for a Fullerette position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company’s history, values, and the specific role you’re applying for. This will demonstrate your interest and preparation.

- Visit the company website to learn about their mission, products, and services.

- Read industry-related articles and news to stay up-to-date on industry trends.

2. Practice Your Skills

Showcase your attention to detail and craftsmanship by practicing your skills beforehand. Present a portfolio or samples of your work to demonstrate your abilities.

- Create a portfolio that includes examples of your best work.

- Practice answering interview questions related to your skills and experience.

3. Highlight Your Customer Service Skills

Emphasize your ability to interact with customers professionally and resolve any concerns they may have. Share examples of your customer service experiences.

- Describe a situation where you successfully resolved a customer complaint.

- Explain your approach to providing exceptional customer service.

4. Be Enthusiastic and Professional

Convey your enthusiasm for the role and the industry. Maintain a professional demeanor throughout the interview, and dress appropriately.

- Share your passion for textiles and garment finishing.

- Come to the interview prepared with questions to ask the interviewer, demonstrating your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fullerette interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!