Are you gearing up for an interview for a Fulling Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fulling Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

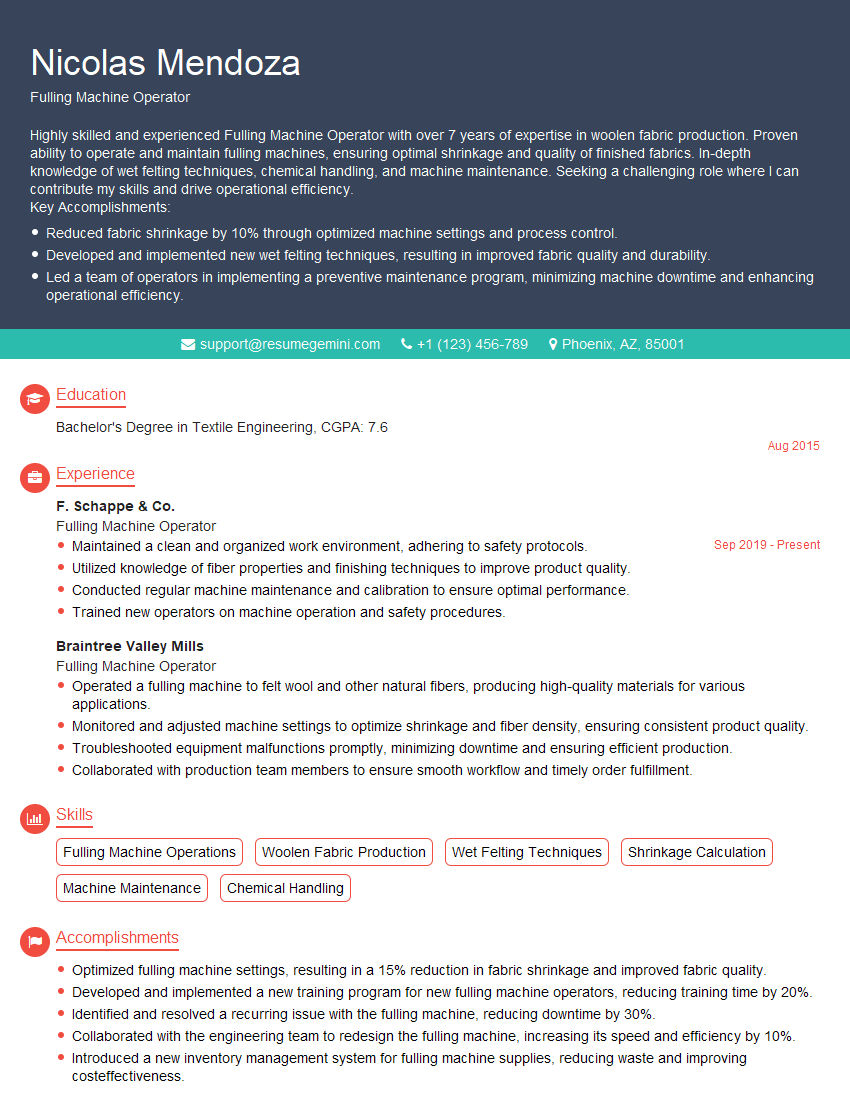

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fulling Machine Operator

1. Describe the process of fulling fabric.

Fulling is a mechanical process used to shrink, thicken, and improve the quality of woven fabric. It involves the following steps:

- Soaking: Fabric is immersed in hot water or a chemical solution to soften the fibers.

- Pounding: The fabric is subjected to repeated pounding or agitation in a fulling mill, which shrinks and interlocks the fibers.

- Scouring: The fabric is washed to remove impurities and excess chemicals.

- Drying: The fabric is dried and stretched to restore its shape and dimensions.

2. Explain the importance of maintaining proper tension during the fulling process.

Maintaining proper tension during the fulling process is crucial for several reasons:

- Fabric quality: Correct tension ensures the fabric shrinks evenly, resulting in a consistent texture and appearance.

- Shrinkage control: By controlling tension, operators can achieve the desired level of fabric shrinkage.

- Machine efficiency: Excessive tension can strain the machine, leading to breakdowns and downtime.

3. How do you troubleshoot common problems encountered in fulling operations?

Common problems encountered in fulling operations include:

- Uneven shrinkage: Troubleshooting involves checking tension settings, fabric moisture content, and machine alignment.

- Excessive shrinkage: Investigate the temperature of the fulling solution, the duration of the fulling cycle, and the fabric type.

- Fabric damage: Inspect the fulling mill for sharp edges or worn-out parts that could damage the fabric.

4. What safety precautions should be followed when operating a fulling machine?

Key safety precautions for operating a fulling machine include:

- Wear appropriate protective gear, such as gloves, eye protection, and earplugs.

- Avoid contact with the moving parts of the machine.

- Keep the work area clean and free of obstacles.

- Follow proper lockout/tagout procedures during maintenance.

5. Describe the benefits of using a fulling agent in the fulling process.

Fulling agents enhance the fulling process by:

- Improving fabric shrinkage: Fulling agents help fibers interlock more effectively.

- Reducing fabric damage: They lubricate the fibers, reducing friction and preventing damage.

- Enhancing fabric texture: Fulling agents contribute to a softer, fuller hand feel.

6. How do you determine the optimal operating parameters for a fulling machine?

To determine the optimal operating parameters for a fulling machine, consider the following factors:

- Fabric type: Different fabrics require different tension settings and fulling durations.

- Desired shrinkage: The operating parameters should be adjusted to achieve the desired level of fabric shrinkage.

- Machine capacity: The machine’s load capacity and speed must be considered to avoid overloading.

7. Explain how you maintain the accuracy of the fulling machine’s measurements.

Maintaining the accuracy of the fulling machine’s measurements involves:

- Regular calibration: The machine should be calibrated using certified standards.

- Inspection and maintenance: Regularly inspect and maintain sensors and measuring devices.

- Operator training: Ensure operators are properly trained to use the machine accurately.

8. How do you minimize waste and optimize fabric utilization during the fulling process?

To minimize waste and optimize fabric utilization during the fulling process:

- Accurate measuring: Use precise measuring techniques to avoid fabric overages.

- Efficient cutting: Implement nesting techniques to maximize fabric utilization.

- Waste reduction: Explore options for reusing or recycling fabric scraps.

9. Discuss the environmental considerations associated with the fulling process.

Environmental considerations associated with the fulling process include:

- Water consumption: Fulling requires large amounts of water, which should be used efficiently.

- Chemical usage: Fulling agents and other chemicals used in the process can have environmental impacts.

- Wastewater treatment: Spent fulling solutions must be treated properly to minimize environmental pollution.

10. How do you ensure the quality of the finished fabric after the fulling process?

To ensure the quality of the finished fabric after the fulling process:

- Inspection: Conduct thorough inspections to identify any defects or inconsistencies.

- Testing: Perform tests to assess fabric shrinkage, strength, and hand feel.

- Continuous improvement: Implement quality control measures and continuously monitor the process to improve quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fulling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fulling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fulling Machine Operator is a skilled individual responsible for operating and maintaining fulling machines used for shrinking and felting wool or other fabric products. Some of the key responsibilities of a Fulling Machine Operator include:

1. Machine Operation and Maintenance

Loading and unloading fabric products into the fulling machine.

- Setting and adjusting machine parameters such as temperature, cycle time, and chemical dosage.

- Monitoring the machine during operation to ensure proper functioning.

- Performing routine maintenance tasks such as cleaning and lubrication.

- Identifying and troubleshooting any mechanical or operational issues.

2. Fabric Handling and Processing

Handling and inspecting fabric products before and after processing to ensure quality.

- Selecting the appropriate fulling process and chemicals for different fabric types.

- Determining the optimal time and temperature for each fabric type to achieve desired results.

- Ensuring proper drying and cooling of fabric products after processing.

3. Quality Control and Inspection

Inspecting fabric products after fulling to verify shrinkage, felting, and overall quality.

- Measuring fabric dimensions and thickness to ensure conformance to specifications.

- Identifying and segregating defective products for rework or rejection.

- Maintaining records and logs of all production and quality control data.

4. Health and Safety Compliance

Adhering to all safety regulations and guidelines while operating the fulling machine.

- Wearing appropriate personal protective equipment (PPE) such as gloves, masks, and goggles.

- Ensuring a clean and organized work area.

- Participating in safety training and refresher courses.

Interview Tips

Preparing for a job interview can be a daunting task, but with the right approach, you can increase your chances of making a great impression. Here are some tips to help you ace your interview for a Fulling Machine Operator position:

1. Research the Company and Position

Before the interview, take some time to research the company you’re applying to and the specific Fulling Machine Operator position. Learn about their history, values, and products/services. Understanding the company’s culture and business operations will help you tailor your answers to their specific needs.

2. Practice Your Answers

Anticipate common interview questions and practice your responses. Consider using the STAR method (Situation, Task, Action, Result) to provide concise and structured answers that highlight your skills and experience. For example, you could practice describing a time when you successfully solved a problem on a fulling machine.

3. Emphasize Relevant Skills and Experience

Highlight your relevant skills and experience that align with the job responsibilities. Showcase your proficiency in operating and maintaining fulling machines, handling and processing fabric products, and conducting quality control inspections. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

4. Ask Questions

At the end of the interview, don’t be afraid to ask questions. This shows that you’re interested in the position and the company. Prepare a few thoughtful questions about the job responsibilities, training opportunities, or company culture. Asking questions also gives you a chance to evaluate whether the company is a good fit for you.

5. Follow Up

After the interview, send a thank-you note to the interviewer. Express your appreciation for their time and reiterate your interest in the position. You can also briefly summarize your key qualifications and how they align with the company’s needs.

Next Step:

Now that you’re armed with the knowledge of Fulling Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Fulling Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini