Are you gearing up for an interview for a Fulling Mill Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fulling Mill Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

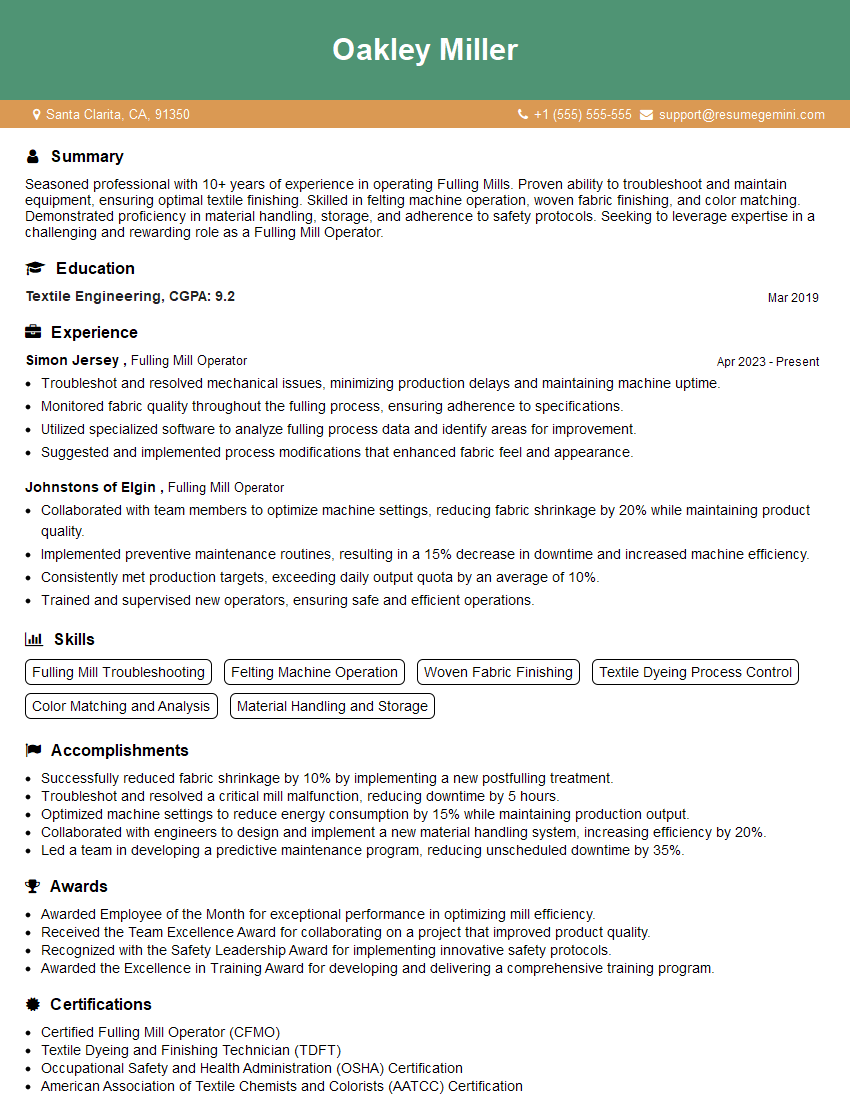

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fulling Mill Operator

1. Describe the process of fulling wool fabric and your role in the process?

- Soaking the wool fabric in a mixture of water and soap called “fulling bath”

- Agitating the fabric to entangle the fibers and create a dense, felted texture

- Monitoring the temperature and pH of the fulling bath to ensure optimal results

- Adjusting the agitation and time to achieve the desired level of felting

- Rinsing and drying the fabric to remove excess soap and moisture

2. Explain the different types of fulling machines and their advantages and disadvantages?

Rotary Fulling Machines

- Advantages: Efficient, large capacity, consistent results

- Disadvantages: High maintenance costs, limited flexibility

Planetary Fulling Machines

- Advantages: Versatile, gentle on fabric, good for delicate fabrics

- Disadvantages: Lower capacity, slower process

Pendulum Fulling Machines

- Advantages: Compact, low maintenance, simple operation

- Disadvantages: Limited capacity, less efficient than rotary machines

3. How do you determine the correct fulling parameters (temperature, agitation, time) for different types of wool fabrics?

Factors to consider:

- Fiber content and quality

- Fabric weight and thickness

- Desired level of felting

- Experience and knowledge of the fabric

- Trial and error to optimize parameters

4. Discuss the potential problems that can arise during fulling and how to troubleshoot them?

- Uneven felting: Adjust agitation or fulling time

- Excessive shrinkage: Reduce fulling time or temperature

- Damage to fabric: Use gentler agitation or lower temperature

- Color bleeding: Use colorfast dyes or add stabilizers to the fulling bath

- Felting of unwanted areas: Protect or mask non-felting areas

5. Explain the importance of maintaining the fulling machine and how to prevent breakdowns?

- Regular cleaning and lubrication

- Inspecting and replacing worn parts

- Monitoring temperature and pH of the fulling bath

- Calibrating and adjusting the machine as needed

- Following manufacturer’s guidelines for maintenance and operation

6. How do you ensure the quality of the fulled fabric and meet customer specifications?

- Adhere to established quality standards

- Inspect fabric for even felting, colorfastness, and shrinkage

- Use measuring devices to ensure dimensions meet specifications

- Keep records of fulling parameters and fabric properties

- Communicate with customers to understand their requirements

7. What are the safety precautions that you must follow when operating a fulling machine?

- Wear appropriate protective gear (gloves, apron, safety glasses)

- Follow lockout/tagout procedures before servicing the machine

- Keep the work area clean and free from tripping hazards

- Be aware of moving parts and avoid contact

- Do not operate the machine if it is malfunctioning or damaged

8. Explain the importance of teamwork and communication in the fulling process?

Factors to consider:

- Coordinating fabric handling and machine operation

- Sharing knowledge and troubleshooting problems

- Communicating quality standards and customer specifications

- Ensuring safety and preventing accidents

- Building a positive and efficient work environment

9. How do you stay updated on the latest advancements in the fulling industry?

- Attend industry events and conferences

- Read trade publications and research articles

- Participate in industry forums and online communities

- Consult with industry experts and suppliers

- Seek opportunities for professional development and training

10. Describe a challenging situation you faced in a previous fulling role and how you overcame it?

Highlight:

- The specific challenge faced

- Steps taken to analyze the problem

- Solutions implemented

- The outcome and lessons learned

- How it improved your skills and knowledge

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fulling Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fulling Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fulling Mill Operator is responsible for the operation and maintenance of fulling mills, which are used to shrink and thicken woolen cloth.

1. Loading and Unloading Cloth

The operator loads and unloads the cloth into and out of the fulling mill.

- Ensuring that the cloth is properly positioned in the mill.

- Making sure that the cloth is not damaged during the loading and unloading process.

2. Operating the Fulling Mill

The operator starts and stops the fulling mill, and adjusts the speed and temperature of the mill as needed.

- Monitoring the mill’s operation to ensure that it is running smoothly.

- Making any necessary adjustments to the mill’s settings.

3. Inspecting the Cloth

The operator inspects the cloth after it has been fulled to ensure that it has been properly processed.

- Checking the cloth for any defects.

- Ensuring that the cloth has the desired shrinkage and thickness.

4. Maintaining the Mill

The operator performs routine maintenance on the fulling mill to ensure that it is in good working condition.

- Cleaning and lubricating the mill’s parts.

- Inspecting the mill’s electrical and mechanical systems.

Interview Tips

To ace an interview for a Fulling Mill Operator position, it is important to be well-prepared. Here are a few tips to help you succeed:

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn about their history, products, and services.

- Read the job description carefully to identify the key responsibilities and qualifications for the position.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is a good idea to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

- Example Outline:

- Tell me about yourself:

- Start with a brief introduction of your educational background and work experience.

- Highlight your skills and qualifications that are relevant to the position.

- End with a statement about why you are interested in the position and the company.

3. Be Enthusiastic and Positive

During your interview, it is important to be enthusiastic and positive about the position and the company. This will show the interviewer that you are genuinely interested in the job and that you are confident in your ability to succeed.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be prepared to talk about your past experiences and how they have prepared you for this position.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer any questions that you have about the position or the company. This shows that you are interested in the job and that you are taking the interview seriously.

- Some good questions to ask include:

- “What is the company culture like?”

- “What are the opportunities for advancement?”

- “What are the biggest challenges facing the company right now?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fulling Mill Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.