Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Furnace and Wash Equipment Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

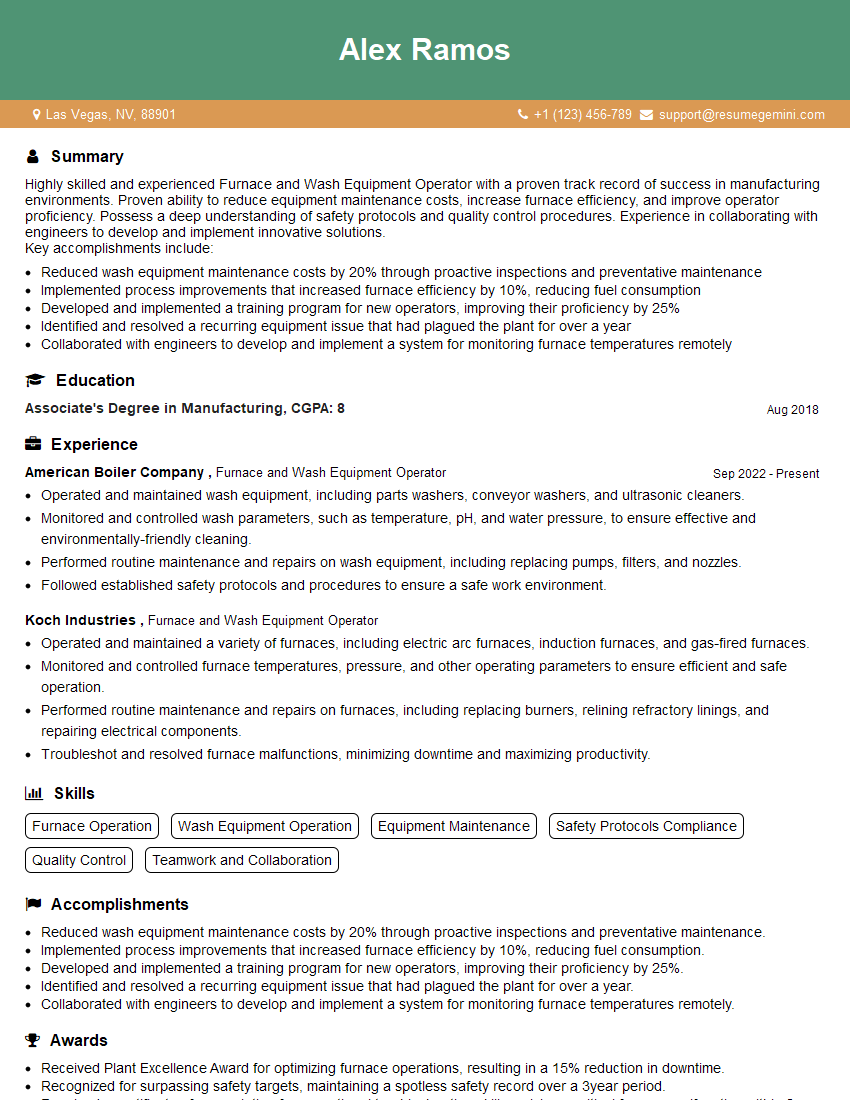

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Furnace and Wash Equipment Operator

1. Can you tell us about the different types of furnaces you’ve worked with and their operating principles?

- Describe the different furnace types, such as electric arc furnaces, induction furnaces, and gas-fired furnaces.

- Explain the operating principles of each type, including the heating methods and temperature control systems.

2. How do you ensure the safe and efficient operation of wash equipment, such as washers, rinsers, and dryers?

Maintenance and Inspections

- Regularly inspect and maintain equipment to ensure optimal performance.

- Follow proper maintenance schedules and keep accurate maintenance records.

Operating Procedures

- Adhere to established operating procedures for each type of equipment.

- Monitor equipment performance and make adjustments as necessary to ensure efficient operation.

Safety Protocols

- Follow all safety protocols and wear appropriate personal protective equipment (PPE).

- Identify and mitigate potential hazards to ensure a safe work environment.

3. How do you handle and store hazardous chemicals used in the operation of furnaces and wash equipment?

- Describe proper storage and handling techniques for hazardous chemicals.

- Explain the importance of following safety data sheets (SDSs) and adhering to regulatory guidelines.

- Discuss the disposal procedures for hazardous waste, including proper waste segregation and disposal methods.

4. Describe the troubleshooting techniques you use when equipment malfunctions occur.

- Explain your systematic approach to identifying and resolving equipment malfunctions.

- Discuss the use of diagnostic tools and techniques to pinpoint the source of the issue.

- Provide examples of successful troubleshooting experiences.

5. How do you maintain a clean and organized work area around furnaces and wash equipment?

- Describe your daily cleaning and maintenance routine for work areas.

- Explain the importance of keeping work areas free of debris and clutter.

- Discuss the use of proper cleaning agents and equipment.

6. Can you explain the importance of preventive maintenance for furnaces and wash equipment?

- Describe the benefits of preventive maintenance, such as reduced downtime, increased equipment longevity, and improved safety.

- Explain the types of preventive maintenance tasks you perform, such as inspections, lubrication, and adjustments.

- Discuss the impact of preventive maintenance on overall plant operations and efficiency.

7. How do you prioritize tasks and manage your workload in a fast-paced production environment?

- Explain your strategies for prioritizing tasks based on urgency and importance.

- Describe how you manage multiple tasks simultaneously without compromising quality or efficiency.

- Discuss the use of time management tools and techniques to optimize your workload.

8. Can you describe your experience with using sensors and instrumentation in the operation of furnaces and wash equipment?

- Explain the different types of sensors and instruments used in these applications.

- Discuss how you interpret and use the data provided by these devices to monitor and control equipment performance.

- Provide examples of how you have used sensors and instrumentation to improve efficiency or troubleshoot issues.

9. What steps do you take to ensure the quality of the products produced by the furnaces and wash equipment?

- Explain the quality control procedures you follow, including inspections and testing.

- Discuss the use of statistical process control (SPC) or other quality management techniques.

- Provide examples of how you have identified and resolved quality issues.

10. How do you stay up-to-date on the latest technologies and best practices in the furnace and wash equipment industry?

- Describe your methods for staying informed about new technologies and advancements.

- Explain how you apply your knowledge to improve your work performance.

- Discuss your interest in attending conferences, workshops, or training programs to enhance your skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Furnace and Wash Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Furnace and Wash Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Furnace and Wash Equipment Operators are responsible for the safe, efficient, and cost-effective operation of a variety of furnace and wash equipment. These pieces of equipment are used to process raw materials in a variety of industries, including the metalworking, automotive, and chemical industries.

1. Furnace Operation

Furnace Operators are responsible for the safe and efficient operation of furnaces. This includes charging the furnace with raw materials, monitoring the temperature and pressure of the furnace, and ensuring that the materials are heated to the correct specifications.

- Charge furnaces with raw materials, such as metal, glass, or plastic.

- Monitor furnace temperature and pressure to ensure that materials are heated to the correct specifications.

- Operate quenching and tempering equipment to heat treat and cool materials.

2. Wash Equipment Operation

Wash Equipment Operators are responsible for the safe and efficient operation of wash equipment. This includes loading the equipment with parts, adding cleaning agents, and ensuring that the parts are cleaned to the correct specifications.

- Load wash equipment with parts to be cleaned.

- Add cleaning agents to the wash equipment.

- Operate wash equipment to clean parts.

3. Maintenance and Repair

Furnace and Wash Equipment Operators are also responsible for the maintenance and repair of their equipment. This includes inspecting equipment for wear and tear, and making repairs as needed. In some cases, they may also be responsible for troubleshooting and resolving equipment problems.

- Inspect furnace and wash equipment for wear and tear.

- Make repairs to furnace and wash equipment.

- Troubleshoot and resolve equipment problems.

4. Quality Control

Furnace and Wash Equipment Operators are responsible for ensuring that the parts they produce meet the required quality standards. This includes inspecting parts for defects, and taking corrective action as needed.

- Inspect parts produced by furnace and wash equipment.

- Take corrective action as needed to ensure that parts meet quality standards.

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Before you go on an interview, it is important to do your research on the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals, and it will also help you to tailor your answers to the interviewer’s questions.

- Visit the company’s website.

- Read about the company in industry publications.

- Talk to people who work for the company.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer interview questions.

- Tell a story that highlights your skills and experience.

- Be specific and provide examples.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the opportunity.

- Dress in business attire.

- Be punctual.

- Be polite and respectful.

4. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know about your skills and experience, so be prepared to talk about them in detail. Highlight your accomplishments and focus on how your skills and experience can benefit the company.

- Quantify your accomplishments whenever possible.

- Use specific examples to illustrate your skills.

- Be enthusiastic and confident.

5. Ask Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position, so be sure to ask thoughtful questions.

- Ask about the company’s culture.

- Ask about the company’s goals.

- Ask about the specific responsibilities of the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Furnace and Wash Equipment Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!