Are you gearing up for an interview for a Furnace Converter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Furnace Converter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

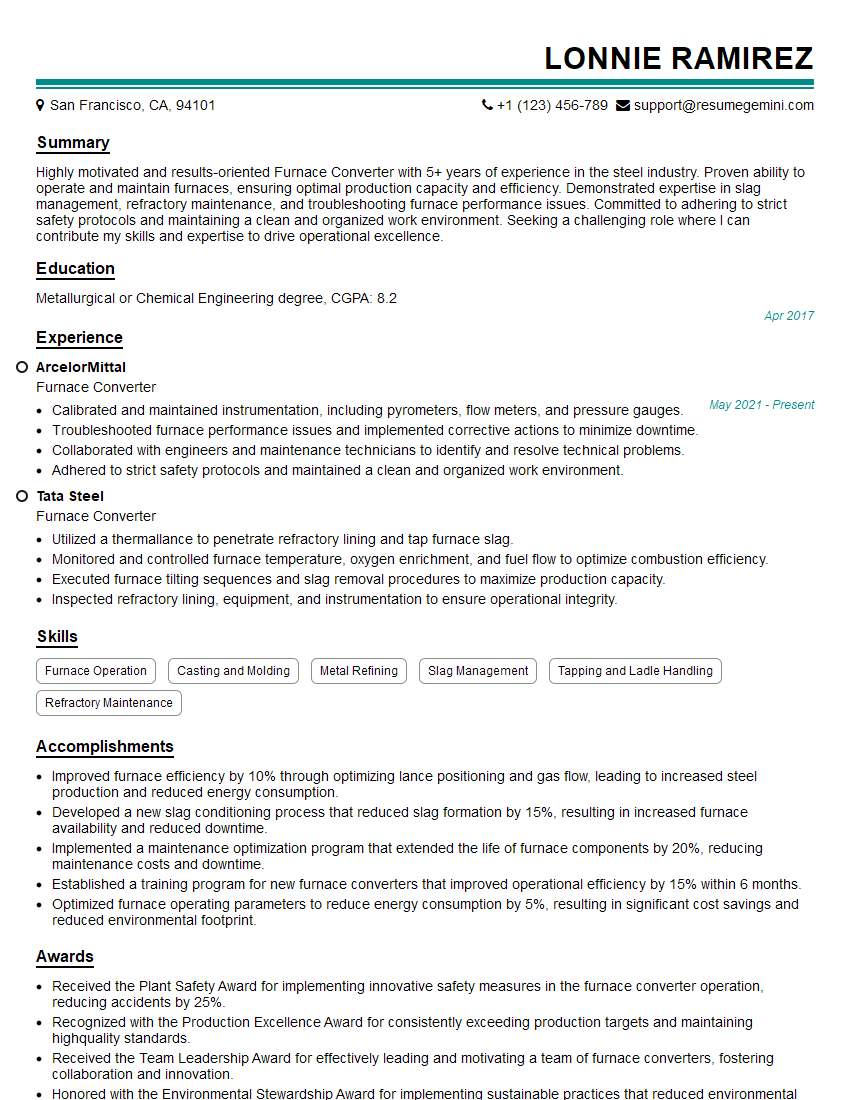

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Furnace Converter

1. How do you monitor and control the temperature of the furnace?

- Using thermocouples installed at strategic locations to measure temperature.

- Adjusting fuel and air flow rates based on temperature readings.

- Monitoring pressure gauges and flow meters to ensure proper combustion and heat transfer.

- Using control systems to automate temperature regulation and optimize process efficiency.

2. Describe the process of charging the furnace with raw materials.

Loading Methods

- Manual charging using overhead cranes or forklifts.

- Automatic charging systems utilizing conveyors or chutes.

Raw Materials Handling

- Verifying the correct materials and quantities are loaded.

- Ensuring proper distribution to optimize melting and refining.

- Preventing contamination or mix-ups during the charging process.

3. Explain the different types of refractories used in a furnace lining and their properties.

- Acid Refractories: Silica bricks and quartz linings, resistant to acid slags.

- Basic Refractories: Magnesia bricks and dolomite linings, suitable for basic slags.

- Neutral Refractories: Alumina-chrome bricks and graphite linings, used in high-temperature zones.

- Monolithic Refractories: Castable or gunned materials, provide flexibility in shape and application.

4. Discuss the safety precautions to be taken when operating a furnace.

- Proper protective gear (gloves, masks, goggles).

- Maintaining safe distances from hot surfaces and moving equipment.

- Regular inspection of equipment for signs of wear or damage.

- Ventilation and exhaust systems to remove fumes and gases.

- Emergency procedures in place for potential hazards (fire, explosions).

5. Describe the process of tapping the furnace and casting the molten metal.

- Tapping: Opening the taphole to allow molten metal to flow into a ladle.

- Ladle Handling: Transporting the molten metal to the casting area.

- Casting: Pouring the molten metal into molds or dies to create desired shapes.

- Cooling and Solidification: Allowing the metal to cool and solidify, forming castings.

6. How do you adjust the composition of the molten metal to meet specific requirements?

- Adding alloying elements or fluxes to modify chemical composition.

- Using slag control techniques to remove impurities or adjust slag chemistry.

- Monitoring and adjusting process parameters (temperature, oxygen levels) to influence metal quality.

- Collaborating with laboratory personnel to analyze samples and provide feedback.

7. Discuss the importance of preventive maintenance for a furnace operation.

- Extending equipment life and reducing downtime.

- Preventing costly repairs and breakdowns.

- Maintaining optimal performance and efficiency.

- Ensuring safety and minimizing potential hazards.

- Complying with industry regulations and standards.

8. How do you troubleshoot common problems that arise in furnace operations?

- Identifying potential causes based on symptoms and process data.

- Checking equipment, sensors, and control systems for malfunctions.

- Implementing corrective actions to resolve issues and restore normal operation.

- Documenting problems, investigations, and solutions for continuous improvement.

- Seeking guidance from experienced personnel or technical experts when necessary.

9. Describe the environmental impact of furnace operations and how you mitigate it.

- Air pollution from combustion gases and particulate matter.

- Water pollution from wastewater and cooling systems.

- Solid waste generation from slag and refractories.

- Mitigation Measures: Scrubbers, baghouses, and electrostatic precipitators to control air pollution.

- Water treatment systems to minimize wastewater discharge.

- Recycling and reuse of waste materials.

10. Explain the role of quality control in furnace operations.

- Ensuring that the molten metal meets the required specifications.

- Monitoring and recording process parameters to maintain consistency.

- Conducting inspections and tests to verify product quality.

- Investigating and resolving quality issues promptly.

- Collaborating with other departments to improve processes and minimize defects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Furnace Converter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Furnace Converter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Furnace Converters are responsible for operating, maintaining, and troubleshooting furnaces used to melt and convert ferrous and non-ferrous metals.

1. Furnace Operations

Maintain and monitor the furnaces’ performance to ensure optimal operation.

- Adjust furnace settings, such as temperature, pressure, and fuel flow.

- Control and monitor the molten metal’s composition and quality.

2. Troubleshooting

Diagnose and resolve any operational issues with the furnaces.

- Identify and address equipment malfunctions, such as leaks, breakdowns, or electrical problems.

- Troubleshoot and rectify process-related issues, ensuring efficient metal conversion.

3. Safety and Maintenance

Ensure a safe and well-maintained work environment within the facility.

- Follow established safety protocols and procedures.

- Perform routine maintenance and repairs on furnaces and associated equipment.

4. Production and Quality Control

Achieve production targets while maintaining quality standards.

- Monitor production processes and make adjustments to optimize output.

- Conduct quality checks to ensure the molten metal meets specifications.

Interview Tips

Preparing thoroughly for an interview is crucial. Here are a few tips to help you ace your Furnace Converter interview:

1. Research the Company and Role

Gather information about the company, its products or services, and the specific responsibilities of the Furnace Converter position. This will show the interviewer that you’re genuinely interested in the opportunity.

- Visit the company’s website, and read their annual reports and recent news articles.

- Use LinkedIn and other networking platforms to connect with current and former employees.

2. Revise Technical Concepts

Brush up on your knowledge of furnaces, metal conversion processes, and industrial safety practices.

- Review textbooks, technical manuals, and online resources.

- Solve practice problems and prepare examples of your troubleshooting and problem-solving abilities.

3. Highlight Relevant Experience

In your resume and interview answers, emphasize your experience operating and maintaining industrial furnaces.

- Quantify your accomplishments with specific metrics whenever possible.

- Use the STAR method (Situation, Task, Action, Result) to describe your past experiences.

4. Prepare for Common Interview Questions

Familiarize yourself with common interview questions and practice your answers beforehand.

- Examples:

- – “Tell us about your experience operating furnaces.”

- – “Describe a time you successfully resolved a complex furnace issue.”

- – “How do you ensure safety in a high-risk work environment?”

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the position and the company.

- Examples:

- – “What are the company’s growth plans for the future?”

- – “Can you elaborate on the technical challenges involved in this role?”

- – “What are the opportunities for professional development and career advancement?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Furnace Converter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!