Feeling lost in a sea of interview questions? Landed that dream interview for Furnace Utility Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Furnace Utility Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

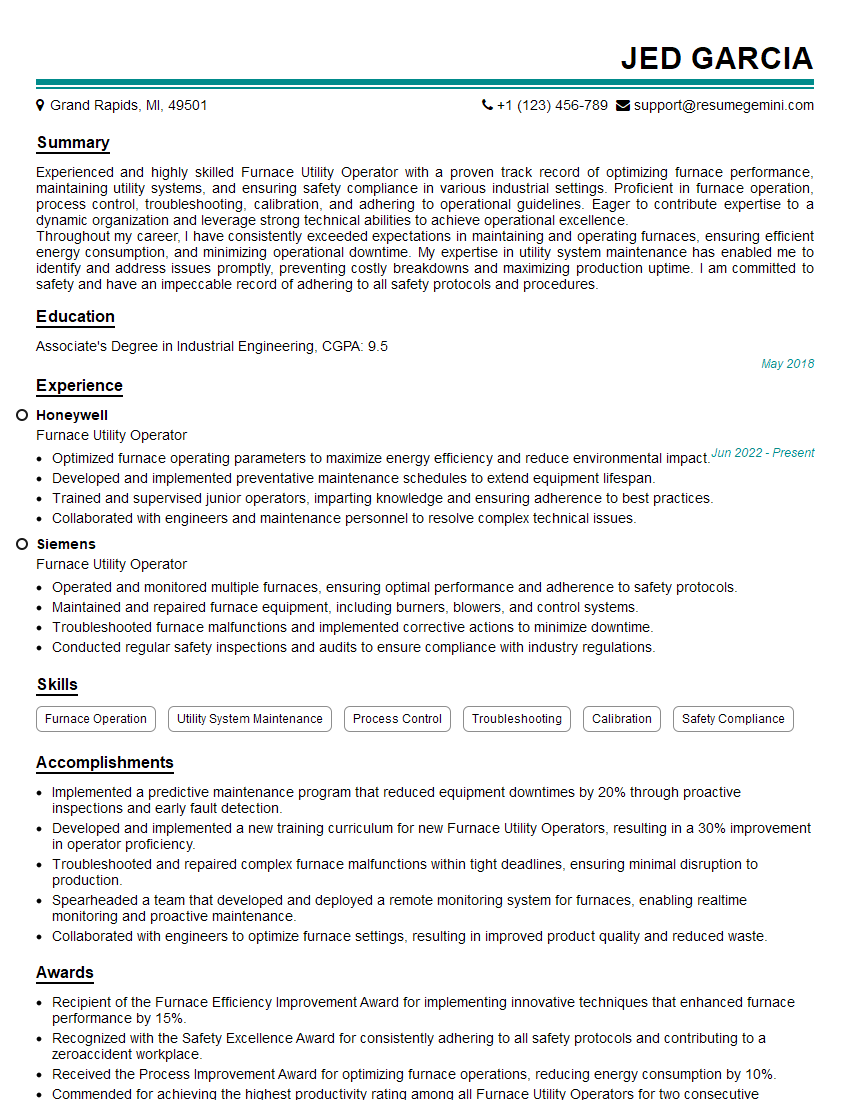

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Furnace Utility Operator

1. Explain the process of operating a furnace?

The process of operating a furnace involves the following steps:

- Pre-heating: The furnace is preheated to a specified temperature before starting the process.

- Loading: The material to be heated is loaded into the furnace.

- Heating: The material is heated to the desired temperature using fuel or electricity.

- Cooling: After reaching the desired temperature, the material is cooled down gradually to prevent damage or cracking.

- Unloading: Once cooled, the material is unloaded from the furnace.

2. What are the different types of furnaces?

- Electric furnaces: Use electricity to generate heat.

- Gas furnaces: Use natural gas or propane to generate heat.

- Oil furnaces: Use oil to generate heat.

- Induction furnaces: Use electromagnetic induction to heat conductive materials.

- Vacuum furnaces: Operate in a vacuum to prevent oxidation and contamination.

3. What are the safety precautions that must be observed when operating a furnace?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and protective clothing.

- Ensure the furnace is properly ventilated to prevent dangerous gas buildup.

- Never operate a furnace with damaged or faulty components.

- Follow all manufacturer’s instructions and safety guidelines.

- Be aware of potential hazards such as hot surfaces, molten metal, and flames.

4. What are the common problems that can occur during furnace operation, and how do you troubleshoot them?

- Temperature fluctuations: Check thermocouples, heating elements, and insulation for issues.

- Material defects: Examine the material for cracks, contamination, or improper loading.

- Equipment malfunctions: Inspect electrical connections, gas lines, and other components for damage or wear.

- Safety issues: Address any potential hazards immediately and shut down the furnace if necessary.

5. How do you monitor and control the temperature of a furnace?

- Use thermocouples or pyrometers to measure temperature.

- Adjust heating elements or gas flow to maintain desired temperature.

- Monitor temperature readings regularly and make adjustments as needed.

- Calibrate temperature measuring devices regularly to ensure accuracy.

6. What maintenance tasks are required for a furnace?

- Regular cleaning: Remove debris, dust, and scale from the furnace.

- Lubrication: Lubricate moving parts to prevent wear and tear.

- Inspection: Check for damage, loose connections, and other issues.

- Calibration: Ensure temperature measuring devices are accurate.

- Replacement of worn parts: Replace any damaged or worn components promptly.

7. How do you ensure the quality of the products heated in a furnace?

- Follow established quality control procedures.

- Inspect materials before and after heating for defects.

- Maintain accurate temperature control to prevent damage or contamination.

- Use appropriate cooling techniques to minimize stress and cracking.

- Document all quality checks and inspections for traceability.

8. What are the environmental regulations that apply to furnace operation?

- Air quality regulations to control emissions.

- Waste disposal regulations for spent materials.

- Energy efficiency regulations to minimize fuel consumption.

- Safety regulations to prevent accidents and injuries.

9. How do you stay updated on the latest technologies and best practices in furnace operation?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with experts and manufacturers.

- Participate in online forums and discussion groups.

10. Why are you interested in this position, and what makes you a suitable candidate?

- Highlight your passion for furnace operation and metallurgy.

- Emphasize your technical skills and experience in furnace operation.

- Mention your understanding of safety regulations and environmental concerns.

- Explain how your skills and knowledge align with the company’s requirements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Furnace Utility Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Furnace Utility Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Furnace Utility Operators are responsible for the efficient and safe operation of furnaces, kilns, and other heat-treating equipment. Their key responsibilities include:

1. Furnace Operation

– Starting and stopping furnaces and kilns – Maintaining proper temperature and heat settings – Monitoring and adjusting the flow of materials through the furnace – Ensuring the quality of finished products

2. Equipment Maintenance

– Performing routine maintenance and repairs on furnaces and kilns – Inspecting equipment for wear and tear – Lubricating and cleaning equipment – Troubleshooting and resolving mechanical problems

3. Process Control

– Monitoring and controlling the temperature, pressure, and other process variables – Adjusting process settings to optimize efficiency and quality – Collecting and analyzing data to improve process performance

4. Safety and Compliance

– Following all safety procedures – Ensuring the proper use of personal protective equipment – Complying with environmental regulations – Maintaining a clean and organized work area

Interview Tips

Preparing for a Furnace Utility Operator interview requires careful research and practice. Here are some tips to help you ace the interview:

1. Research the Company and Industry

– Learn about the company’s values, mission, and products or services. – Research the industry trends and technological advancements related to furnace operation.

2. Review the Job Description

– Carefully review the job description and identify the key responsibilities and skills required. – Prepare examples from your past experiences that demonstrate your ability to fulfill these requirements.

3. Practice Your Answers

– Anticipate common interview questions and prepare thoughtful and concise answers. – Practice your responses out loud to improve your delivery and confidence.

4. Highlight Your Skills and Experience

– Emphasize your technical skills, such as furnace operation, equipment maintenance, and process control. – Showcase your experience in a similar role and highlight your accomplishments.

5. Be Enthusiastic and Professional

– Dress appropriately and arrive for the interview on time. – Maintain eye contact and be enthusiastic about the opportunity. – Ask thoughtful questions that demonstrate your interest in the position and the company.

6. Example Outline

When answering interview questions, consider structuring your responses using the STAR method:

- Situation: Briefly describe the situation or task you faced.

- Task: Explain the specific task you were responsible for completing.

- Action: Describe the actions you took to complete the task.

- Result: State the outcome or result of your actions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Furnace Utility Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!