Feeling lost in a sea of interview questions? Landed that dream interview for Furniture Fabricator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Furniture Fabricator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

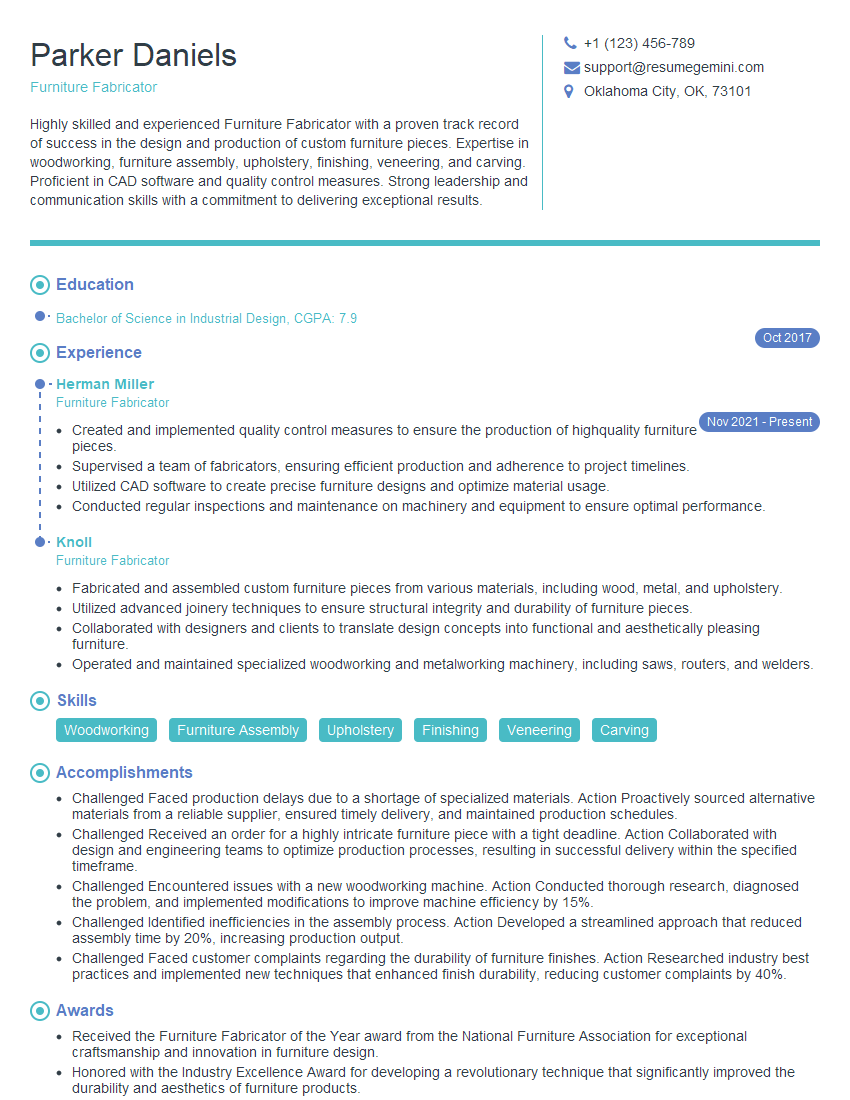

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Furniture Fabricator

1. How would you approach creating a custom furniture piece for a client with specific requirements?

- First, I consult with the client to understand their needs, including their desired style, function, and budget.

- I then create a design that meets their specifications, taking into account the available space and materials.

- Once the design is approved, I select the appropriate materials and begin the fabrication process.

- Throughout the project, I communicate regularly with the client to ensure their satisfaction and address any changes.

2. What are the different types of wood joints used in furniture making, and when would you choose each type?

Mortise and Tenon

- Strong and durable joint for load-bearing structures.

- Used in chairs, tables, and bed frames.

Dovetail

- Highly durable and aesthetically pleasing joint.

- Used in drawers and boxes.

Rabbet

- Joins two pieces of wood at a right angle.

- Used in shelves and picture frames.

3. How do you ensure the accuracy and quality of your furniture pieces?

- I use precise measuring and cutting tools to ensure accuracy.

- I pay attention to detail and inspect each piece carefully before assembly.

- I use high-quality materials and finishes to ensure durability and aesthetic appeal.

- I regularly calibrate my tools and maintain my workshop to ensure optimal performance.

4. Can you list the most important factors to consider when selecting upholstery materials for furniture?

- Durability: The material should be able to withstand wear and tear.

- Comfort: The material should be comfortable to sit or lie on.

- Aesthetic appeal: The material should complement the style of the furniture.

- Maintenance: The material should be easy to clean and maintain.

- Cost: The material should fit within the project’s budget.

5. What are the different methods of upholstery attachment, and when would you use each method?

Tacking

- Simple and quick method using tacks.

- Used for temporary or inexpensive upholstery.

Stapling

- More secure and durable method using staples.

- Used for most types of upholstery, including sofas, chairs, and headboards.

Sewing

- Creates a strong and tailored seam.

- Used for more complex upholstery projects, such as cushions and pillows.

6. How do you handle customer complaints or requests for repair or modification?

- I listen attentively to the customer’s concerns.

- I inspect the furniture piece to identify the issue.

- I discuss repair or modification options with the customer.

- I provide a timeline and cost estimate for the work.

- I ensure the customer is satisfied with the outcome.

7. What are the current trends in furniture design and fabrication?

- Sustainable materials and eco-friendly practices.

- Multifunctional furniture that adapts to changing spaces.

- Smart furniture with integrated technology.

- Customizable and modular designs.

- Geometric and organic shapes.

8. What software programs do you use for furniture design and drawing?

- AutoCAD

- SketchUp

- SolidWorks

- Fusion 360

- Vectric Aspire

9. How do you keep up with the latest advancements in furniture making techniques and materials?

- Attend industry trade shows and workshops.

- Read industry publications and online articles.

- Network with other furniture makers and designers.

- Experiment with new techniques and materials.

10. Do you have experience with furniture finishing, such as staining, painting, or distressing?

- Yes, I have extensive experience in furniture finishing.

- I am proficient in various techniques, including staining, painting, distressing, and glazing.

- I understand the properties of different finishes and their impact on the appearance and durability of furniture.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Furniture Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Furniture Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Furniture Fabricators are responsible for creating and repairing furniture pieces using various materials, including wood, metal, and fabric. They work in a workshop or factory setting and use specialized tools and equipment to complete their projects. Key job responsibilities of a Furniture Fabricator include:

1. Building furniture from scratch

Using blueprints or design sketches, Furniture Fabricators cut, shape, and assemble furniture components to create new furniture pieces. They use a variety of tools, including saws, drills, and hammers, to complete this task.

- Interpret blueprints or design sketches to determine the specifications of the furniture piece.

- Select and prepare materials, such as wood, metal, or fabric, for use in the furniture piece.

- Cut, shape, and assemble furniture components using tools such as saws, drills, and hammers.

- Finish the furniture piece by applying paint, stain, or other finishes.

2. Repairing furniture

Furniture Fabricators also repair damaged furniture pieces. They assess the damage and determine the best course of action to repair the piece. They may need to replace damaged parts, refinish the piece, or make other repairs.

- Assess the damage to the furniture piece and determine the best course of action for repair.

- Replace damaged parts or refinish the piece as needed.

- Make other repairs, such as tightening loose joints or repairing upholstery.

3. Upholstering furniture

Some Furniture Fabricators also specialize in upholstering furniture. This involves covering furniture pieces with fabric or leather. Upholsterers use a variety of techniques to complete this task, including hand-stitching, machine-stitching, and tacking.

- Select and prepare fabric or leather for use in upholstering furniture.

- Cut and sew fabric or leather to fit the furniture piece.

- Attach fabric or leather to the furniture piece using hand-stitching, machine-stitching, or tacking.

- Finish the upholstered furniture piece by applying trims or other decorative elements.

4. Working with customers

Furniture Fabricators may also work with customers to design and create custom furniture pieces. They discuss the customer’s needs and preferences, and then create a design that meets the customer’s requirements.

- Meet with customers to discuss their needs and preferences for custom furniture pieces.

- Create designs for custom furniture pieces based on the customer’s input.

- Build and finish custom furniture pieces according to the customer’s specifications.

- Deliver and install custom furniture pieces at the customer’s location.

Interview Tips

To ace an interview for a Furniture Fabricator position, it is important to prepare thoroughly and showcase your skills and experience. Here are some tips to help you prepare for the interview:

1. Research the company and the position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and tailor your answers to the interviewer’s questions accordingly.

- Visit the company’s website to learn about its history, mission, and products or services.

- Read online reviews of the company to get a sense of its culture and employee satisfaction.

- Check out the company’s social media pages to see what kind of content they post and how they interact with their followers.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions ahead of time so that you can deliver your responses confidently and concisely.

- Use the STAR method to answer behavioral interview questions. This involves describing a Situation, Task, Action, and Result from your previous experience.

- Be prepared to talk about your skills and experience in detail. Highlight your strengths and accomplishments, and be specific about how you have applied your skills to achieve results.

- Be prepared to ask the interviewer questions. This shows that you are interested in the position and the company, and that you have done your research.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment. You should also arrive on time for your interview, as punctuality shows that you are respectful of the interviewer’s time.

- Choose clothing that is clean, pressed, and appropriate for the office environment.

- Avoid wearing clothing that is too revealing, too casual, or too trendy.

- Arrive on time for your interview. If you are running late, call the interviewer to let them know.

4. Be yourself and be confident

It is important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and your experience, and let the interviewer see your passion for furniture making.

- Be honest and genuine in your answers to the interviewer’s questions.

- Don’t be afraid to show your enthusiasm for furniture making.

- Be confident in your abilities and your experience.

5. Follow up after the interview

After the interview, be sure to send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and to reiterate your interest in the position. You can also use the thank-you note to highlight any specific skills or experiences that you feel would be valuable to the company.

- Send a thank-you note to the interviewer within 24 hours of the interview.

- In your thank-you note, reiterate your interest in the position and highlight any specific skills or experiences that you feel would be valuable to the company.

- Follow up with the interviewer a week or two after the interview to inquire about the status of your application.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Furniture Fabricator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.