Are you gearing up for a career in Furniture Lumber Production Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Furniture Lumber Production Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

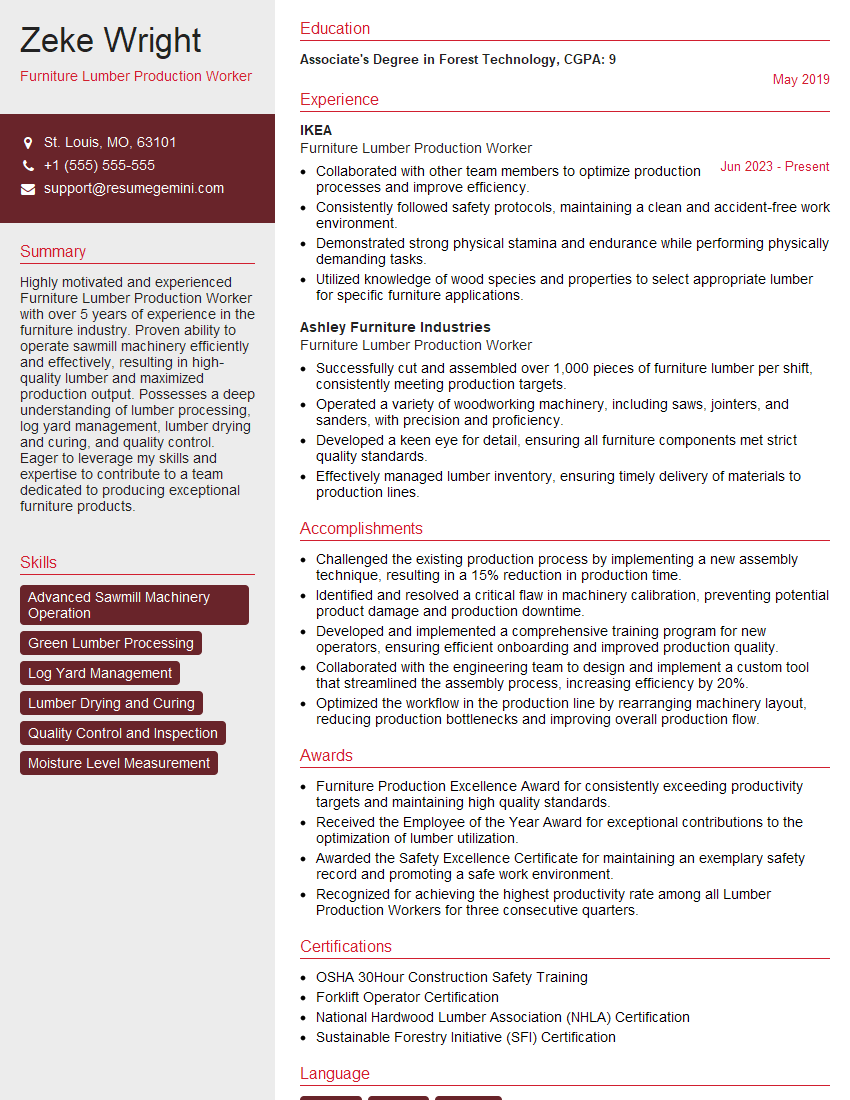

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Furniture Lumber Production Worker

1. What is the difference between softwood and hardwood?

- Softwood comes from coniferous trees, which have needles and cones.

- Hardwood comes from deciduous trees, which have broad leaves that change color in the fall.

- Softwood is generally less dense and more flexible than hardwood.

- Hardwood is generally more durable and resistant to decay than softwood.

2. What are the different types of lumber grades?

Hardwood Grades

- FAS (First and Seconds) – Clear, free of defects

- Select – Few defects, suitable for high-quality furniture

- No. 1 Common – Some defects, suitable for general construction

- No. 2 Common – More defects, suitable for low-grade furniture

- No. 3 Common – Many defects, suitable for crates and pallets

Softwood Grades

- Select Structural – Clear, free of defects

- No. 1 – Few defects, suitable for high-quality construction

- No. 2 – Some defects, suitable for general construction

- No. 3 – More defects, suitable for low-grade construction

- No. 4 – Many defects, suitable for crates and pallets

3. What are the most common types of woodworking joints?

- Butt joint – Two pieces of wood are joined end-to-end.

- Edge joint – Two pieces of wood are joined along their edges.

- Miter joint – Two pieces of wood are joined at an angle.

- Mortise and tenon joint – A mortise is cut into one piece of wood, and a tenon is cut into another piece of wood. The tenon is then inserted into the mortise.

- Dovetail joint – A series of interlocking pins and tails are cut into two pieces of wood. The pins and tails are then fitted together to create a strong joint.

4. What are the different types of woodworking tools?

- Hand tools – Saws, hammers, chisels, planes, etc.

- Power tools – Drills, sanders, routers, etc.

- Stationary tools – Table saws, band saws, jointers, etc.

5. What are the safety precautions that should be taken when working with lumber?

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Use sharp tools and keep them in good condition.

- Be aware of your surroundings and potential hazards.

- Do not operate machinery unless you are trained and authorized to do so.

- Follow all safety instructions and procedures.

6. What is your experience with operating woodworking machinery?

- I have 5 years of experience operating a variety of woodworking machinery, including table saws, band saws, jointers, and routers.

- I am proficient in setting up and operating these machines safely and efficiently.

- I have a strong understanding of the different types of woodworking machinery and their uses.

7. How do you ensure that the lumber you produce meets the required specifications?

- I follow all of the company’s quality control procedures.

- I use precise measuring tools and equipment to ensure that the lumber is cut to the correct dimensions.

- I inspect the lumber for any defects before it is shipped out.

8. What are the different types of finishes that can be applied to lumber?

- Stains – Penetrate the wood and change its color.

- Paints – Form a film on the surface of the wood.

- Varnishes – Clear finishes that protect the wood from moisture and wear.

- Shellacs – Natural finishes that are made from the resin of the lac beetle.

- Polyurethanes – Synthetic finishes that are durable and resistant to scratches and dents.

9. What is your experience with working in a team environment?

- I have worked in a team environment for the past 5 years.

- I am able to work well with others to achieve common goals.

- I am a good communicator and I am always willing to help out my team members.

10. Why are you interested in working for our company?

- I am interested in working for your company because I am impressed with your commitment to quality and customer service.

- I believe that my skills and experience would be a valuable asset to your team.

- I am eager to learn more about your company and to contribute to its success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Furniture Lumber Production Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Furniture Lumber Production Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Furniture Lumber Production Worker, you will be primarily responsible for assisting in the production of furniture lumber by performing various tasks in a furniture manufacturing facility. Some of the key responsibilities that you will be expected to fulfill include:

1. Lumber Preparation

Preparing lumber for processing includes tasks like unloading and sorting incoming lumber, making necessary cuts, and feeding lumber into machines for further processing.

2. Operating Machinery

You will be expected to operate a range of machinery used in furniture production, such as saws, planers, and sanders, to process lumber and shape it into various components. Monitoring and adjusting these machines to ensure optimal performance and product quality is also included in this responsibility.

3. Quality Assurance

You will need to inspect lumber and furniture components throughout the production process to ensure they meet established quality standards. Identifying and reporting any defects or irregularities is crucial to maintain the high quality of the finished products.

4. Material Handling

Moving and handling lumber and furniture components within the production area is another important aspect of your role. Using forklifts, cranes, or other equipment to safely and efficiently transport materials is essential to keep the production process running smoothly.

Interview Tips

To help you ace your interview for a Furniture Lumber Production Worker position, here are some preparation tips to consider.

1. Research the Company and Industry

Before the interview, it’s essential to research the furniture manufacturing company and the industry as a whole. Understanding the company’s mission, products, and market position will demonstrate your interest and eagerness to contribute. Additionally, familiarizing yourself with industry trends and practices will help you participate in meaningful discussions.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that highlight your skills and experience. Practice answering questions about your proficiency in operating machinery, experience with quality control processes, and ability to work in a fast-paced manufacturing environment.

3. Showcase Your Physical Capabilities

Furniture Lumber Production is a physically demanding role. During the interview, emphasize your physical fitness and ability to perform tasks that involve lifting, carrying, and maneuvering heavy objects. Highlight any relevant experience or certifications that demonstrate your strength and endurance.

4. Highlight Your Safety Awareness

Safety is paramount in a manufacturing environment. Emphasize your understanding of safety protocols and your commitment to following them strictly. Share examples of your safety consciousness in previous roles or personal experiences. Mention any training or certifications related to workplace safety that you may possess.

5. Convey Your Enthusiasm and Eagerness to Learn

Express your genuine interest in the furniture industry and your eagerness to learn new skills and contribute to the team. Show enthusiasm for the opportunity to work in a dynamic production environment and contribute to the creation of quality furniture products.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Furniture Lumber Production Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!