Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fuse Cutter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fuse Cutter so you can tailor your answers to impress potential employers.

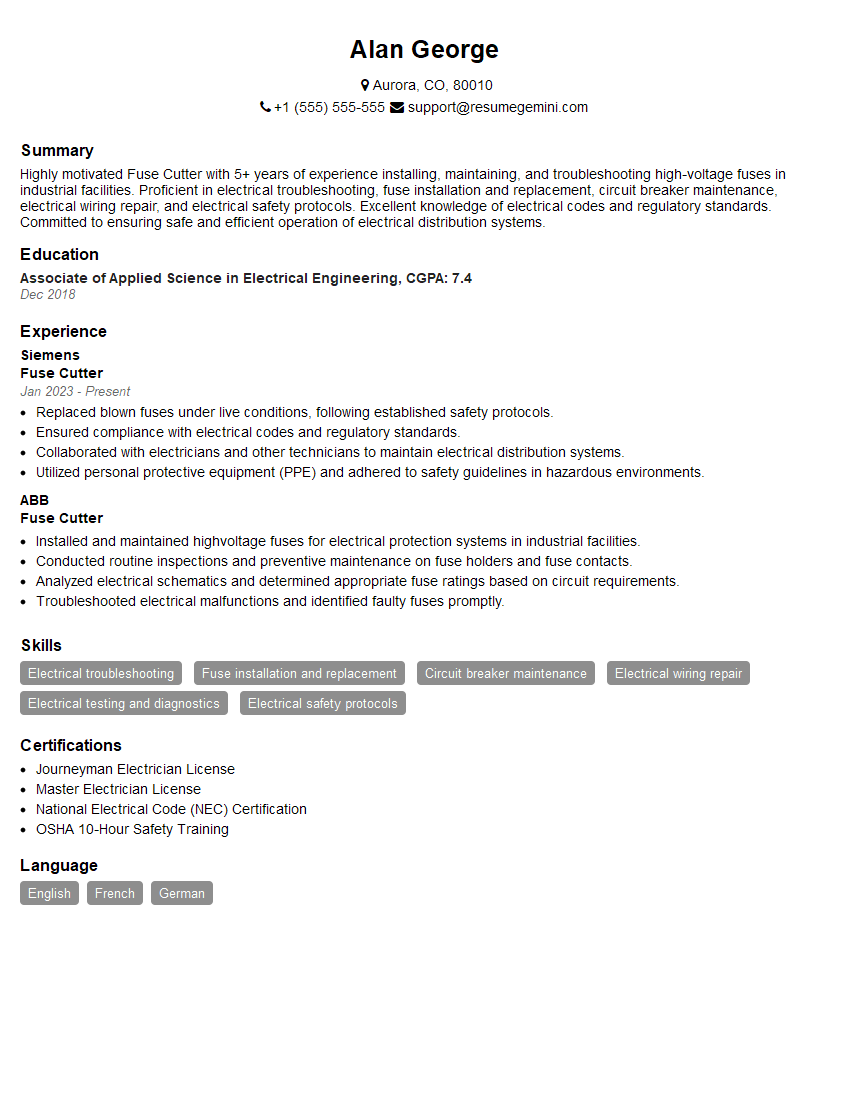

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fuse Cutter

1. What safety precautions should be taken when operating a fuse cutter?

To ensure safe operation of a fuse cutter, it is crucial to adhere to the following safety precautions:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a face shield.

- Inspect the fuse cutter thoroughly before each use, checking for any damage or loose connections.

- Ensure that the fuse cutter is properly grounded to prevent electrical shocks.

- Never attempt to cut live fuses, as this poses a significant electrical hazard.

- Secure the fuse cutter firmly in place before cutting to prevent it from moving or slipping.

- Follow the manufacturer’s instructions for the specific fuse cutter being used.

2. How do you determine the appropriate size and type of fuse to use in a specific application?

Fuse Rating and Amperage

- Identify the electrical load and its current draw in amperes.

- Select a fuse with an amperage rating that is slightly higher than the load’s current draw.

- Consider the operating temperature and any potential overloads or surges.

Fuse Type and Characteristics

- Choose the appropriate fuse type based on the electrical system (AC or DC) and the required protection characteristics.

- Consider the fuse’s voltage rating, interrupting capacity, and speed of operation.

- Refer to the equipment manufacturer’s specifications or consult with an electrician for specific recommendations.

3. What are the different techniques for cutting fuses?

There are several techniques for cutting fuses, each with its advantages and applications:

- Manual Fuse Cutter: Utilizes a lever or handle to manually cut the fuse element.

- Pneumatic Fuse Cutter: Employs compressed air to power the cutting mechanism, providing greater force.

- Hydraulic Fuse Cutter: Uses hydraulic pressure to drive the cutting blades, offering precision and high cutting force.

- Laser Fuse Cutter: Employs a laser beam to vaporize the fuse element, resulting in a clean and precise cut.

- Explosive Fuse Cutter: Utilizes a small explosive charge to sever the fuse element, ensuring a safe and controlled cut.

4. How do you calibrate a fuse cutter to ensure accurate and consistent cuts?

Fuse cutter calibration is essential for precise and reliable performance:

- Follow the manufacturer’s calibration instructions for the specific fuse cutter being used.

- Use a certified calibration gauge or fuse of known length to set the cutting distance.

- Ensure that the cutting blades are sharp and aligned properly.

- Check the calibration regularly to maintain accuracy, especially after extended use or blade replacement.

- Keep a record of calibration checks for documentation and quality control purposes.

5. What are the common troubleshooting steps for a fuse cutter that is not cutting correctly?

If a fuse cutter is not cutting correctly, consider these troubleshooting steps:

- Inspect the fuse cutter for any visible damage or loose connections.

- Check the fuse holder to ensure that it is properly secured and making good contact.

- Examine the cutting blades for sharpness and alignment. Replace or sharpen the blades if necessary.

- Verify that the fuse cutter is calibrated correctly and that the cutting distance is set appropriately.

- Consult the manufacturer’s instructions or seek professional assistance if the issue persists.

6. What types of fuses can be cut using a fuse cutter, and are there any limitations?

Fuse cutters are designed to cut a variety of fuse types, including:

- Glass Tube Fuses

- Ceramic Body Fuses

- Blade Fuse

- Knife Blade Fuses

- Bolt-In Fuse

Limitations:

- Fuse cutters may have limitations on the maximum fuse size or amperage they can cut.

- Certain types of fuses, such as high-voltage or liquid-filled fuses, may require specialized cutting tools.

- Fuse cutters are not designed to cut live fuses, as this poses a significant electrical hazard.

7. How do you dispose of used fuses safely and according to industry regulations?

Proper disposal of used fuses is crucial for safety and environmental protection:

- Allow used fuses to cool completely before handling.

- Check local regulations and guidelines for specific disposal methods.

- Recycle fuses whenever possible through designated collection programs.

- Dispose of non-recyclable fuses at authorized hazardous waste disposal facilities.

- Never dispose of fuses in regular trash or by incineration.

8. What are the key maintenance tasks for a fuse cutter to ensure optimal performance and longevity?

Regular maintenance is essential to keep a fuse cutter operating optimally and extend its lifespan:

- Clean the fuse cutter regularly to remove any dust, debris, or electrical residue.

- Inspect the cutting blades for sharpness and alignment, replacing or sharpening them as necessary.

- Check the electrical connections and ensure they are tight and secure.

- Calibrate the fuse cutter periodically to maintain accurate cutting distance.

- Store the fuse cutter in a clean, dry place when not in use.

9. Can you explain the different types of fuse cutter blades and their applications?

Fuse cutter blades come in various types, each designed for specific applications:

- Standard Blades: General-purpose blades suitable for cutting most types of fuses.

- Notched Blades: Blades with small notches designed for cutting smaller fuses or fuses with delicate elements.

- Angled Blades: Blades with an angled cutting edge for precise cutting of fuses in tight spaces.

- Heavy-Duty Blades: Blades made from durable materials for cutting larger or more robust fuses.

- Specialty Blades: Blades designed for specific types of fuses, such as high-voltage or liquid-filled fuses.

10. What are the safety considerations for working with high-voltage fuses?

Handling high-voltage fuses requires strict adherence to safety protocols:

- Always wear appropriate PPE, including non-conductive gloves, safety glasses, and a face shield.

- Ensure that the work area is well-ventilated and free of any potential hazards.

- Use insulated tools and equipment specifically designed for high-voltage applications.

- Verify that the fuse cutter is properly rated for the voltage of the fuses being cut.

- Never attempt to cut live fuses. Allow them to cool completely before handling.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fuse Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fuse Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fuse Cutter is a crucial member of an electrical team, responsible for ensuring the safe and efficient operation of electrical systems. Their primary duty is to cut and prepare fuses to the correct specifications.

1. Fuse Cutting and Preparation

Fuse Cutters are experts in cutting and preparing fuses to the exact specifications required for specific electrical circuits. They use specialized tools and techniques to accurately cut and crimp fuses, ensuring optimal performance and safety.

- Measure and cut fuses to the required length

- Crimp fuse ends to connect them to electrical wires

- Inspect fuses for defects and ensure proper fit

2. Electrical System Maintenance

Fuse Cutters play a role in maintaining electrical systems by replacing blown fuses, conducting inspections, and performing repairs. They work closely with electricians to keep systems running smoothly and safely.

- Replace blown fuses promptly to restore power

- Conduct visual inspections of electrical components

- Assist electricians with repairs and troubleshooting

3. Safety Compliance

Fuse Cutters prioritize safety in all aspects of their work. They adhere to strict safety protocols and regulations to minimize risks and protect themselves and others. They also ensure that fuses are properly rated and installed to prevent electrical hazards.

- Follow established safety protocols

- Wear appropriate personal protective equipment (PPE)

- Use proper tools and techniques to handle fuses safely

4. Teamwork and Communication

Fuse Cutters collaborate with other electrical team members, including electricians and supervisors, to ensure efficient and effective operations. They effectively communicate information, share knowledge, and work together to troubleshoot and resolve issues.

- Collaborate with electricians on electrical projects

- Provide feedback and suggestions to improve processes

- Participate in training and development opportunities

Interview Preparation Tips

To ace your interview for a Fuse Cutter position, there are several preparation tips and hacks to consider.

1. Research the Company and Industry:

Learn about the company’s background, mission, and values. Research the electrical industry and stay updated on current trends and regulations. This knowledge will demonstrate your interest and enthusiasm for the field.

- Visit the company website and LinkedIn page

- Read industry publications and news articles

- Attend industry events and conferences

2. Practice Your Answers:

Prepare for common interview questions by rehearsing your answers. Focus on highlighting your skills, experience, and qualifications that align with the key responsibilities of a Fuse Cutter.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses

- Provide specific examples to demonstrate your abilities

- Practice answering questions in front of a mirror or with a friend

3. Prepare Questions for the Interviewer:

Asking thoughtful questions shows your engagement and interest in the position. Prepare insightful questions about the company, the role, and the team you would be joining.

- Inquire about the company’s growth plans and industry outlook

- Ask about the specific responsibilities and expectations of the Fuse Cutter role

- Seek information about the team’s dynamics and company culture

4. Dress and Behave Professionally:

First impressions matter. Dress professionally and arrive on time for your interview. Maintain a polite and respectful demeanor throughout the process.

- Choose formal attire such as a suit or business casual outfit

- Arrive punctually and greet the interviewer with a firm handshake

- Maintain eye contact and speak clearly and confidently

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fuse Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.