Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fuse Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fuse Maker so you can tailor your answers to impress potential employers.

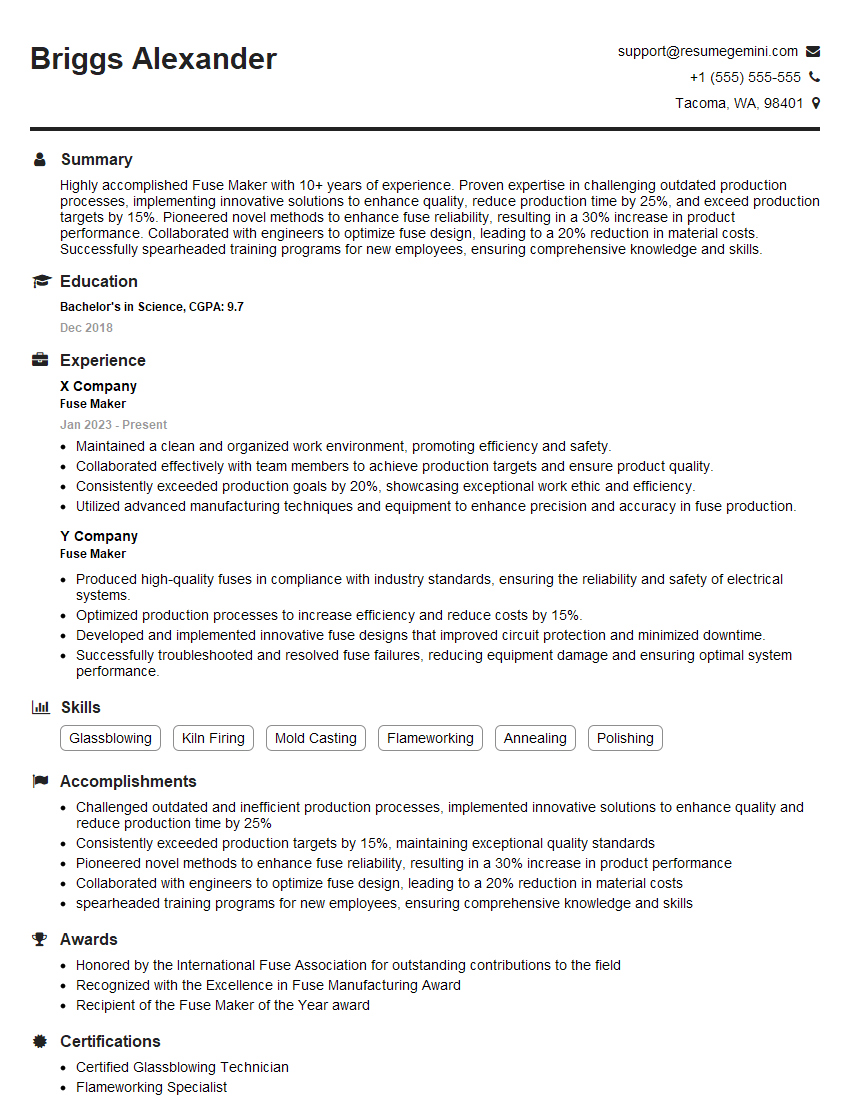

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fuse Maker

1. What is the purpose of a fuse in an electrical system, and what are the different types of fuses available?

- A fuse is a safety device that protects an electrical system from damage by breaking the circuit when the current exceeds a predetermined level.

- There are various types of fuses available, such as cartridge fuses, glass fuses, and miniature fuses, each with its specific characteristics and applications.

2. Explain the process of fuse manufacturing, including the materials used and the steps involved.

Material Selection

- The selection of materials is crucial, including the conductor, fuse body, and filler materials.

- Common conductor materials are silver, copper, and alloys, chosen for their low resistance and high melting point.

Steps Involved

- The conductor is shaped and calibrated to meet the desired current rating and breaking capacity.

- The conductor is enclosed in a fuse body, typically made of ceramic or glass, to provide insulation and protection.

- The fuse body is filled with a filler material, such as sand or quartz, to extinguish the arc and prevent explosions.

- The fuse is then sealed and tested to ensure proper operation and compliance with standards.

3. Describe the factors that determine the current rating and breaking capacity of a fuse.

- Current rating: Determined by the cross-sectional area and material of the conductor.

- Breaking capacity: Determined by the design and construction of the fuse, including the arc suppression mechanism and the ability to withstand high fault currents.

4. Explain the role of arc quenching in fuse design and its importance for safety.

- Arc quenching is essential to prevent sustained arcing, which can cause explosions and damage to equipment.

- Fuse designs incorporate arc quenching mechanisms, such as sand or quartz fillers, to absorb the arc energy and dissipate it as heat.

- Effective arc quenching ensures safe operation and prevents catastrophic consequences.

5. How do you ensure the quality and reliability of fuses in manufacturing?

- Rigorous testing and quality control procedures are essential.

- Testing includes electrical, mechanical, and environmental tests to verify performance and compliance with standards.

- Statistical process control and continuous improvement programs are implemented to maintain quality and reliability throughout production.

6. Discuss the environmental considerations and regulations related to fuse manufacturing.

- Fuse manufacturing must adhere to environmental regulations, such as RoHS and REACH.

- Materials and processes are selected to minimize environmental impact.

- Waste management and recycling programs are implemented to reduce environmental footprint.

7. Explain the different types of fuse holders and their applications.

- Fuse holders provide a safe and convenient way to mount and replace fuses.

- Types include panel mount, DIN rail mount, and cartridge fuse holders.

- Each type has specific applications based on voltage, current rating, and environmental conditions.

8. Describe the importance of proper fuse selection and installation in electrical systems.

- Correct fuse selection and installation are crucial for electrical safety.

- Oversizing or undersizing fuses can lead to system failures and hazards.

- Proper installation ensures reliable operation and prevents loose connections or damage to the fuse holder.

9. How do you stay updated on the latest developments and trends in fuse technology?

- Attending industry conferences and trade shows.

- Reading technical journals and articles.

- Engaging with experts and professionals in the field.

- Researching new materials and manufacturing techniques.

10. What are your strengths and weaknesses as a Fuse Maker?

- Expertise in fuse manufacturing processes and materials.

- Strong understanding of electrical safety and fuse performance.

- Ability to troubleshoot and resolve production issues.

- Limited experience in automated fuse manufacturing.

- Working on improving efficiency and waste reduction.

Strengths

Weaknesses

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fuse Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fuse Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fuse makers play a crucial role in manufacturing by creating fuses, safety devices used in electrical circuits. Their key responsibilities include:

1. Fuse Design and Production

Fuse makers create and produce fuses with specific dimensions, materials, and current ratings, ensuring they meet industry standards and customer requirements.

- Designing fuse dimensions and selecting materials based on specifications.

- Manufacturing fuses using specialized equipment and techniques.

2. Quality Control

Fuse makers conduct quality control checks throughout the production process to ensure the reliability and safety of fuses.

- Performing electrical tests to verify fuse performance.

- Inspecting fuses for defects and adherence to specifications.

3. Equipment Maintenance

Fuse makers maintain and calibrate equipment used in fuse production, ensuring efficient and accurate manufacturing.

- Cleaning and lubricating machinery regularly.

- Performing preventive maintenance to avoid production disruptions.

4. Compliance and Safety

Fuse makers follow safety protocols and adhere to industry and company standards to ensure a safe working environment.

- Complying with OSHA regulations and other safety guidelines.

- Wearing appropriate personal protective equipment.

Interview Tips

To ace the interview for a Fuse Maker position, candidates should consider the following tips:

1. Research the Company and Position

Gather information about the company’s operations, industry, and specific job responsibilities to demonstrate your interest and knowledge.

- Review the company website and social media.

- Read industry publications and articles related to fuse manufacturing.

2. Practice Common Interview Questions

Prepare for common interview questions, such as:

- Tell me about your experience in fuse manufacturing.

- How do you ensure the quality and safety of fuses?

- What knowledge do you have of industry standards and regulations?

3. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as equipment operation, quality control, and electrical testing. Discuss your experience in a similar role and how it has prepared you for this position.

4. Demonstrate Safety Awareness

Stress your commitment to safety and your knowledge of industry protocols. Highlight your experience in maintaining a safe work environment and your adherence to safety regulations.

5. Ask Thoughtful Questions

Show your interest and engagement by asking informed questions about the company, the position, and the industry. This demonstrates your genuine desire to learn more and contribute to the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fuse Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!