Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fuselage Framer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

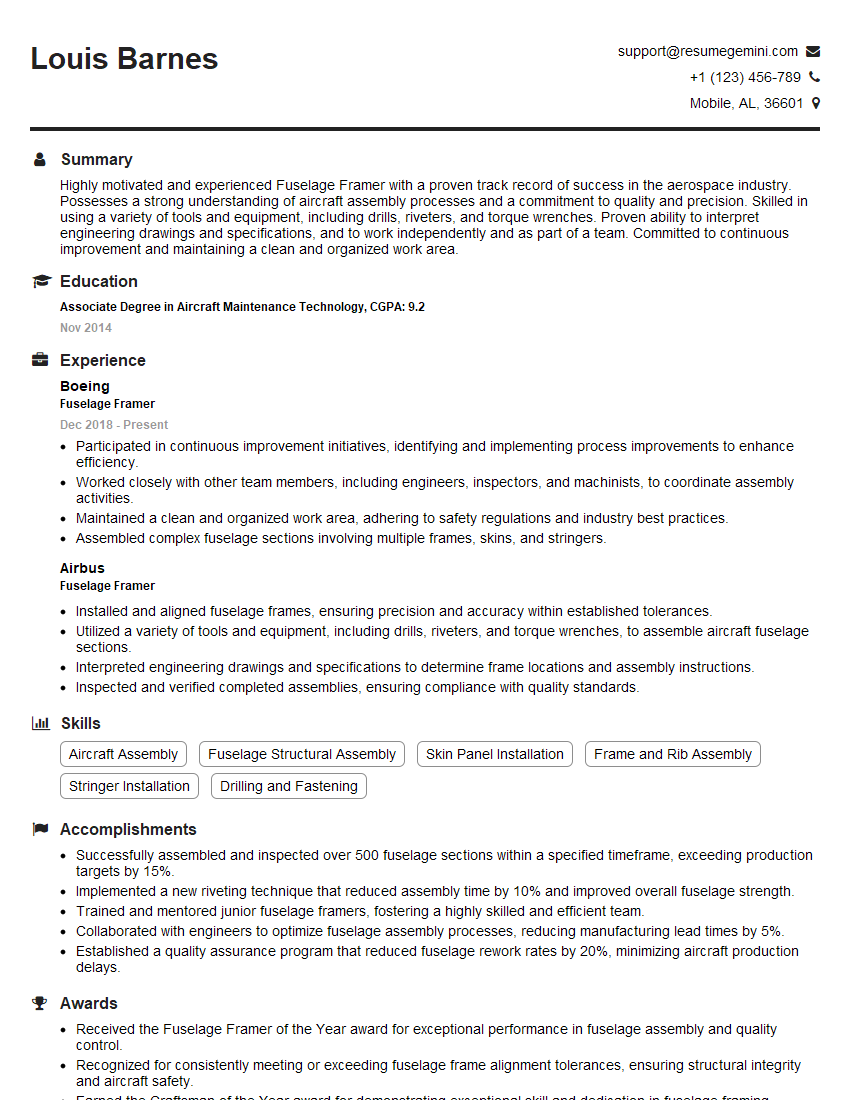

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fuselage Framer

1. Describe the steps involved in installing a fuselage frame assembly?

- Prepare the fuselage frame assembly for installation by cleaning and deburring the mating surfaces.

- Position the fuselage frame assembly in the fuselage and secure it temporarily with clamps or bolts.

- Align the fuselage frame assembly with the surrounding structure using a level or transit.

- Tighten the bolts or clamps to secure the fuselage frame assembly in place.

- Inspect the installation to ensure that it meets all applicable specifications.

2. How do you ensure the accuracy of fuselage frame assembly installation?

subheading of the answer

- Use precision measuring tools and equipment, such as levels, transits, and micrometers.

- Follow the manufacturer’s instructions and specifications for the installation process.

- Inspect the installation at each step to ensure that it meets the required tolerances.

- Have a qualified inspector verify the accuracy of the installation before proceeding with subsequent assembly steps.

subheading of the answer

- Use jigs and fixtures to hold the fuselage frame assembly in place during installation.

- Use a laser alignment system to ensure that the fuselage frame assembly is aligned with the surrounding structure.

- Use a coordinate measuring machine (CMM) to verify the accuracy of the installation.

3. What are the different types of fuselage frame assemblies and their applications?

- Bulkhead frames: These frames are used to divide the fuselage into compartments and to provide support for the aircraft’s interior.

- Floor frames: These frames are used to support the aircraft’s floor and to provide a mounting surface for seats and other equipment.

- Skin frames: These frames are used to attach the aircraft’s skin to the fuselage structure.

- Stringer frames: These frames are used to provide longitudinal support for the fuselage skin.

- Spar frames: These frames are used to support the aircraft’s wings and to provide a mounting surface for the aircraft’s engines.

4. What are the materials used in fuselage frame assemblies and their properties?

- Aluminum alloys: These alloys are lightweight and strong, and they are resistant to corrosion.

- Steel alloys: These alloys are strong and durable, but they are heavier than aluminum alloys.

- Composite materials: These materials are lightweight and strong, and they are resistant to corrosion and fatigue.

- Titanium alloys: These alloys are strong and lightweight, but they are expensive.

5. What are the welding and riveting techniques used in fuselage frame assembly fabrication?

- Gas tungsten arc welding (GTAW): This welding technique is used to join thin sheets of metal.

- Gas metal arc welding (GMAW): This welding technique is used to join thicker sheets of metal.

- Resistance spot welding (RSW): This welding technique is used to join two sheets of metal together by applying heat and pressure.

- Riveting: This technique is used to join two sheets of metal together by inserting a rivet through the sheets and then deforming the rivet to hold the sheets together.

6. How do you ensure the quality of fuselage frame assemblies?

- Use qualified personnel to perform the fabrication and assembly work.

- Use high-quality materials and components.

- Follow the manufacturer’s instructions and specifications for the fabrication and assembly process.

- Inspect the fuselage frame assemblies at each step to ensure that they meet the required tolerances.

- Have a qualified inspector verify the quality of the fuselage frame assemblies before they are installed in the aircraft.

7. Describe the tools and equipment used in fuselage frame assembly fabrication.

- Sheet metal shears

- Sheet metal brakes

- Welding machines

- Riveting machines

- Inspection tools

8. What are the safety precautions that must be taken when working with fuselage frame assemblies?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a hard hat.

- Use caution when working with sharp tools and equipment.

- Be aware of the potential for burns and electrical hazards.

- Follow all safety procedures and guidelines.

9. What is the role of a fuselage framer in the aircraft manufacturing process?

- Fabricates and assembles fuselage frame assemblies.

- Inspects fuselage frame assemblies to ensure that they meet the required tolerances.

- Installs fuselage frame assemblies in the aircraft.

- Performs other related tasks as assigned.

10. What are the challenges of working as a fuselage framer?

- The work can be physically demanding.

- The work can be repetitive.

- The work can be dangerous.

- The work can be stressful.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fuselage Framer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fuselage Framer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fuselage Framers are crucial members of the aircraft manufacturing team, responsible for assembling and joining the aircraft’s fuselage. Their primary duties include:

1. Fuselage Assembly

Framers assemble and join fuselage components, such as panels, frames, and skins, using various techniques like riveting, bonding, and welding.

- Interpreting blueprints and work orders to ensure correct assembly

- Positioning and aligning fuselage components precisely

2. Installation of Systems

They install electrical, hydraulic, and other systems within the fuselage, ensuring proper alignment and functionality.

- Mounting and connecting electrical wires and harnesses

- Installing hydraulic lines, ducts, and other components

3. Inspection and Quality Control

Framers perform thorough inspections of the assembled fuselage to ensure it meets quality standards and specifications.

- Checking for proper fit and alignment

- Conducting dimensional and visual inspections

4. Troubleshooting and Maintenance

They troubleshoot and resolve any assembly issues that arise, maintaining the fuselage’s integrity.

- Identifying and rectifying defects or errors

- Maintaining and repairing fuselage components as needed

Interview Tips

To ace an interview for a Fuselage Framer position, follow these tips:

1. Research the Company and Industry

Demonstrating knowledge of the company’s history, products, and industry trends shows genuine interest and preparedness.

- Visit the company website, read industry publications, and attend webinars

- Highlight how your skills and experience align with the company’s goals

2. Emphasize Relevant Skills and Experience

Fuselage Framers require a combination of technical expertise and practical experience. Highlight the following:

- Proficiency in aircraft assembly techniques, such as riveting and welding

- Experience in working with blueprints and technical drawings

- Knowledge of aircraft systems and components

3. Showcase Safety and Quality Mindset

Safety and quality are paramount in aircraft manufacturing. Emphasize your:

- Commitment to following safety protocols and maintaining a clean and organized work area

- Understanding of quality control standards and the importance of precise assembly

- Experience in identifying and resolving defects or errors

4. Prepare for Technical Questions

Interviewers may ask technical questions to assess your understanding of fuselage assembly. Prepare for questions related to:

- Different aircraft fuselage types and their construction techniques

- Quality control procedures and inspection methods

- Troubleshooting common fuselage assembly issues

5. Be Enthusiastic and Flexible

Fuselage Framers work in a dynamic and demanding environment. Show your:

- Enthusiasm for the aviation industry and the role of a Fuselage Framer

- Ability to work efficiently in a team and adapt to changing priorities

- Willingness to learn and grow within the organization

Next Step:

Now that you’re armed with the knowledge of Fuselage Framer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Fuselage Framer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini