Feeling lost in a sea of interview questions? Landed that dream interview for Fusing Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fusing Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

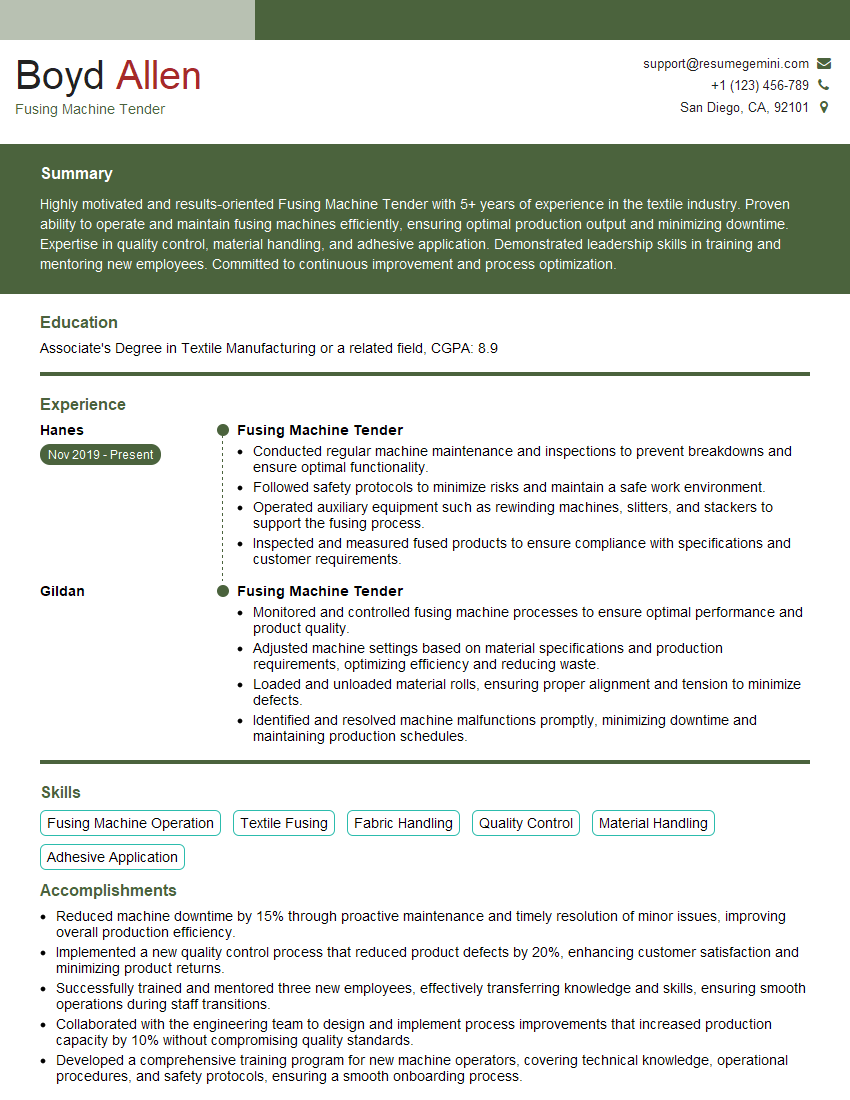

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fusing Machine Tender

1. Explain the process of fusing interlinings?

- Inspect interlinings for any defects.

- Preheat the fusing machine to the appropriate temperature.

- Place the interlining on the fusing machine conveyor belt.

- Fuse the interlining by passing it through the heated rollers.

- Inspect the fused interlining for any defects.

- Package the fused interlining for shipment.

2. How do you ensure the quality of the fused interlinings?

Visual inspection

- Check for any tears, holes, or other defects.

- Ensure that the interlining is properly fused.

- Inspect the interlining for any color variations.

Dimensional inspection

- Check the length and width of the interlining.

- Ensure that the interlining is cut to the correct size.

- Inspect the interlining for any thickness variations.

Performance testing

- Test the interlining for its strength and durability.

- Ensure that the interlining can withstand the stresses of garment construction.

- Inspect the interlining for any shrinkage or distortion.

3. What are the common problems that can occur during fusing and how do you troubleshoot them?

- Wrinkles: Ensure that the interlining is properly tensioned and that the fusing machine is set to the correct temperature.

- Bubbles: Check for any air pockets in the interlining and smooth them out before fusing.

- Scorching: Reduce the fusing temperature or speed of the fusing machine.

- Bleeding: Use a lower fusing temperature and avoid using interlinings that are prone to bleeding.

- Delamination: Ensure that the interlining is properly fused and that the adhesive is compatible with the fabric.

4. What is the difference between dry and wet fusing?

- Dry fusing: Uses heat to activate the adhesive on the interlining.

- Wet fusing: Uses steam to activate the adhesive on the interlining.

Advantages of dry fusing:

- Faster and more efficient.

- Produces a stronger bond.

- Less likely to cause damage to the fabric.

Advantages of wet fusing:

- Produces a softer and more flexible bond.

- Can be used on delicate fabrics.

- Less likely to cause shrinkage or distortion.

5. What are the different types of fusing machines?

- Roller fusing machine: Uses heated rollers to fuse the interlining to the fabric.

- Belt fusing machine: Uses a heated conveyor belt to fuse the interlining to the fabric.

- Plate fusing machine: Uses a heated plate to fuse the interlining to the fabric.

Factors to consider when choosing a fusing machine:

- Type of fabric being fused.

- Type of interlining being used.

- Production volume.

- Available budget.

6. What is the role of pressure in fusing?

- Pressure helps to activate the adhesive on the interlining.

- Pressure helps to create a stronger bond between the interlining and the fabric.

- Too much pressure can damage the fabric.

- Too little pressure can result in a weak bond.

7. What are the safety precautions that must be taken when operating a fusing machine?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a dust mask.

- Keep the fusing machine clean and free of debris.

- Never operate the fusing machine unsupervised.

- Follow all manufacturer’s instructions for safe operation.

8. What is your experience with different types of fusing machines?

- I have experience with roller fusing machines, belt fusing machines, and plate fusing machines.

- I am familiar with the different settings and operating procedures for each type of machine.

- I have a proven track record of operating fusing machines safely and efficiently.

9. What is your knowledge of different types of interlinings and their applications?

- I am familiar with a wide range of interlinings, including woven, non-woven, and knit interlinings.

- I understand the different properties of each type of interlining and how they affect the performance of the finished garment.

- I can recommend the appropriate interlining for a given application based on the fabric, garment construction, and desired performance.

10. How do you stay up-to-date on the latest fusing techniques and technologies?

- I attend industry trade shows and conferences.

- I read industry publications and online resources.

- I consult with experts in the field.

- I am always looking for ways to improve my skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fusing Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fusing Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fusing Machine Tenders are responsible for the operation and maintenance of fusing machines, which bond together layers of fabric or other materials using heat and pressure. Their key responsibilities include:

1. Machine Operation

Fusing Machine Tenders are responsible for operating fusing machines, which bond together layers of fabric or other materials using heat and pressure.

- Setting up and adjusting the fusing machine according to the specified parameters.

- Loading and unloading the fusing machine with materials, ensuring proper alignment and tension.

2. Quality Control

Fusing Machine Tenders are responsible for monitoring the quality of the fused materials and making adjustments as necessary.

- Inspecting the fused materials for defects such as wrinkles, bubbles, or delamination.

- Adjusting the machine settings or making repairs as needed to maintain quality standards.

3. Maintenance and Troubleshooting

Fusing Machine Tenders are responsible for performing routine maintenance and troubleshooting on the fusing machine.

- Cleaning and lubricating the machine regularly.

- Identifying and resolving minor malfunctions.

- Reporting major issues to a supervisor for further action.

4. Safety and Compliance

Fusing Machine Tenders are responsible for following all safety and compliance procedures.

- Wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Following established lockout/tagout procedures before performing maintenance.

- Complying with all applicable environmental regulations.

Interview Tips

Preparing for a Fusing Machine Tender interview can help you present yourself confidently and increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and the specific responsibilities of the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice answering questions about the company and the position.

3. Be Enthusiastic and Positive

Hiring managers are looking for candidates who are enthusiastic and positive about the role. Show your interest in the position and the company by being engaged and asking questions.

- Smile and make eye contact with the interviewer.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

4. Dress Professionally

First impressions matter, so be sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Choose conservative colors and avoid wearing anything too revealing or distracting.

- Make sure your shoes are clean and polished.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fusing Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!