Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gage Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

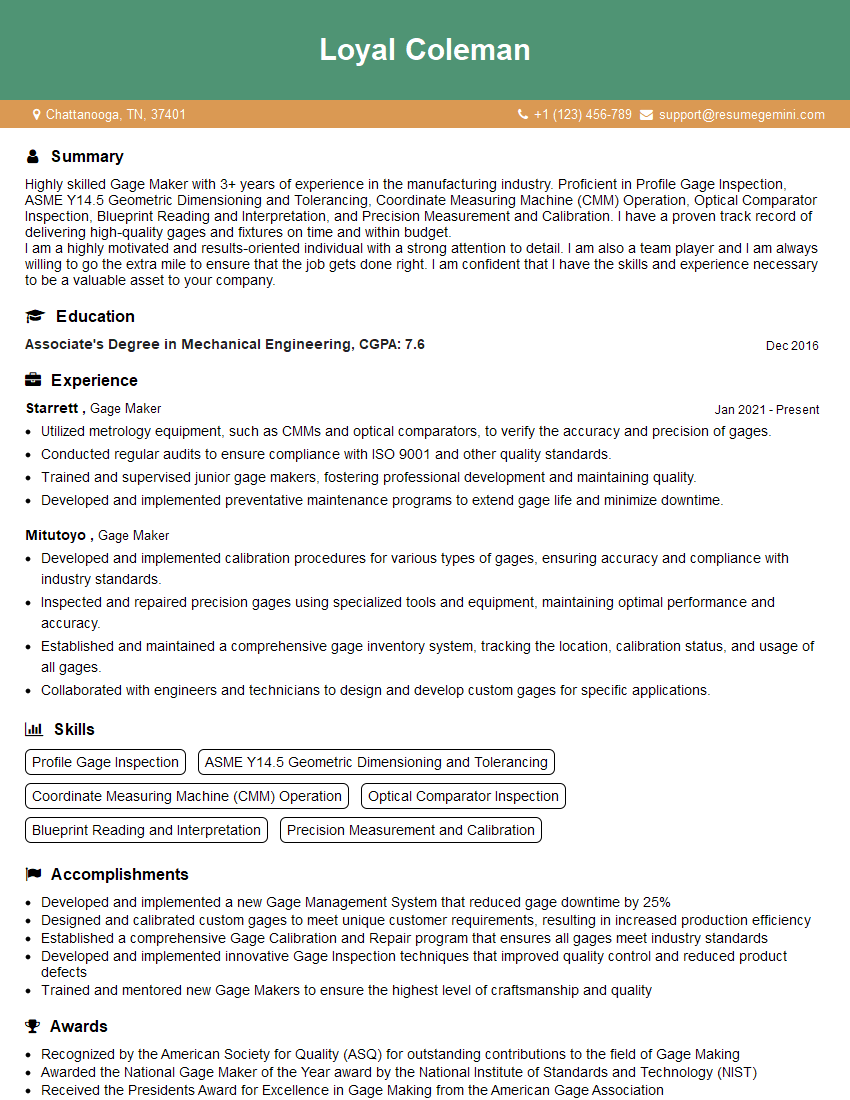

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gage Maker

1. What are the different types of gages used for inspecting dimensions?

- Plug and ring gages (for measuring internal and external diameters)

- Thread gages (for measuring thread pitch, angle, and form)

- Snap gages (for measuring thickness, height, or width)

- Dial indicators (for measuring small displacements or variations)

- Optical comparators (for comparing an object to a master sample)

- Coordinate measuring machines (CMMs) (for measuring complex shapes)

2. How do you calibrate and maintain gage accuracy?

Calibration process

- Use certified reference standards

- Compare the gage’s readings to the standards

- Adjust or repair the gage as necessary

Maintenance practices

- Clean gages regularly

- Store gages properly (in a controlled environment)

- Perform periodic inspections

3. What are the potential errors that can occur when using gages?

- Calibration errors (incorrect reference standards, improper calibration techniques)

- Environmental errors (temperature variations, vibration)

- Operator errors (misreading scales, incorrect measurement methods)

- Gage errors (deformation, wear)

4. How do you determine if a part is within tolerance using a gage?

- Measure the part using the appropriate gage

- Compare the measurement to the specified tolerance

- Determine if the part is within the tolerance range (acceptable) or outside the tolerance range (reject)

5. What are the advantages of using automated gaging systems?

- Increased accuracy and precision

- Reduced inspection time

- Improved data recording and storage

- Reduced operator errors

- Increased efficiency and productivity

6. What are the different types of materials used in gage construction?

- Steel

- Ceramic

- Granite

- Composite materials

7. How do you ensure the traceability of gage measurements?

- Maintain a calibration log

- Document gage use and maintenance

- Use certified reference standards

- Participate in proficiency testing programs

8. What are the quality standards and regulations that apply to the use of gages?

- ISO 9001

- ASTM E1106 Standard for Calibration of Gages

- ANSI/ASQ Z1.4 Standard for Gage Calibration and Testing

9. How do you handle gages that are damaged or worn out?

- Remove the gage from service immediately

- Calibrate the gage if possible. If not, replace it.

- Dispose of the damaged or worn-out gage properly

10. What are the key skills and qualifications required to be a successful Gage Maker?

- Strong knowledge of metrology and gaging principles

- Proficient in using a variety of gages

- Skilled in calibration and maintenance of gages

- Excellent attention to detail and accuracy

- Ability to work independently and as part of a team

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gage Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gage Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gage Makers are skilled professionals responsible for designing, fabricating, and calibrating precision measuring instruments called gages. These gages play a crucial role in maintaining industry standards, ensuring product quality, and facilitating efficient manufacturing processes.

1. Design and Blueprint Interpretation

Read and comprehend engineering drawings and blueprints to translate design specifications into functional gages.

- Analyze design requirements, dimensions, and tolerances.

- Select appropriate materials and components based on gage specifications.

2. Gage Fabrication

Use specialized tools, machines, and techniques to fabricate gage components and assemble complete gages.

- Operate lathes, milling machines, grinders, and other precision equipment.

- Ensure dimensional accuracy and surface finishes meet design requirements.

3. Gage Calibration and Certification

Calibrate gages against certified standards to ensure their accuracy and reliability.

- Use specialized calibration equipment and techniques to adjust gages and bring them within specified tolerances.

- Prepare calibration reports and maintain documentation.

4. Quality Control and Inspection

Conduct quality checks on incoming materials and finished gages to ensure compliance with standards.

- Use measuring instruments, such as calipers, micrometers, and coordinate measuring machines (CMMs), to verify dimensions and tolerances.

- Identify and correct any discrepancies or deviations from specifications.

Interview Tips

To ace an interview for a Gage Maker position, it is essential to demonstrate a thorough understanding of the job responsibilities, technical skills, and industry knowledge. Here are some tips and hacks to help you prepare:

1. Research the Company and Industry

Familiarize yourself with the company’s history, business model, and product line. Understand the industry trends and technological advancements related to gage making.

- Visit the company website and LinkedIn page.

- Read industry publications and attend relevant conferences.

2. Highlight your Technical Skills

Emphasize your proficiency in using precision tools, machines, and calibration equipment. Quantify your experience and provide specific examples of successful gage fabrication and calibration projects.

- Describe your experience with lathes, milling machines, grinders, and CMMs.

- Explain how you have calibrated gages against certified standards and maintained calibration records.

3. Showcase your Quality Assurance Mindset

Demonstrate your commitment to quality control and attention to detail. Highlight your ability to identify and correct discrepancies, and your adherence to industry standards.

- Share examples of your involvement in quality improvement initiatives.

- Explain how you ensure the traceability and accuracy of gage measurements.

4. Prepare for Technical Questions

Expect technical questions related to gage design, fabrication, calibration, and quality control. Study basic principles of metrology, dimensional tolerancing, and calibration techniques.

- Practice answering questions on topics such as gage design principles, materials selection, and calibration methods.

- Be ready to discuss your experience with different types of gages and their applications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gage Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!