Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gantry Rigger position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

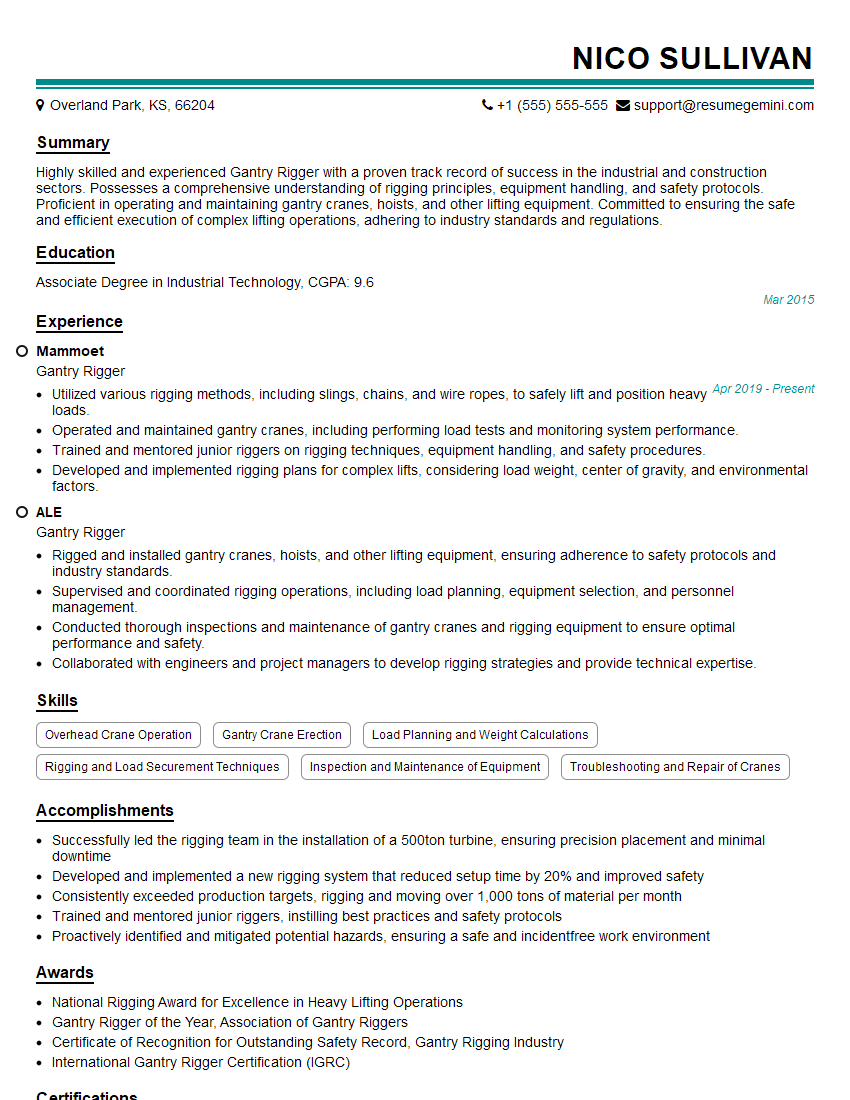

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gantry Rigger

1. Tell me about your experience as a Gantry Rigger.

I have been working as a Gantry Rigger for the past 5 years. In this role, I am responsible for the safe and efficient operation of gantry cranes. I am also responsible for the maintenance and repair of these cranes. I have a strong understanding of the principles of rigging and have a proven track record of working safely and efficiently.

2. What are the different types of gantry cranes and what are their uses?

Types of Gantry Cranes

- Single girder gantry crane

- Double girder gantry crane

- Four girder gantry crane

- Straddle gantry crane

Uses of Gantry Cranes

- In shipbuilding

- In container terminals

- In workshops

- In warehouses

3. What are the safety precautions that you take when operating a gantry crane?

When operating a gantry crane, I always take the following safety precautions:

- I always make sure that the crane is in good working order before operating it.

- I always wear the appropriate safety gear, including a hard hat, safety glasses, and gloves.

- I always follow the manufacturer’s instructions for operating the crane.

- I always make sure that the load is properly secured before lifting it.

- I always stay clear of the load when it is being lifted or lowered.

4. What are the signs of wear and tear on a gantry crane that you look for during inspections?

- Cracks in the metal

- Loose bolts or nuts

- Worn or damaged gears

- Leaking hydraulic fluid

- Excessive noise or vibration

5. What are the different types of rigging that you use and what are their applications?

- Synthetic slings: These slings are made of high-strength synthetic fibers and are lightweight and easy to handle. They are ideal for lifting delicate or fragile loads.

- Wire rope slings: These slings are made of steel wire rope and are very strong and durable. They are ideal for lifting heavy loads.

- Chain slings: These slings are made of steel chain and are also very strong and durable. They are ideal for lifting loads that are hot or abrasive.

6. What are the different types of hitches that you use and what are their applications?

- Basket hitch: This hitch is used to lift a load that is evenly balanced.

- Choker hitch: This hitch is used to lift a load that is not evenly balanced.

- Bridle hitch: This hitch is used to lift a load that is very heavy or that needs to be lifted at an angle.

7. What are the principles of safe lifting?

- Plan the lift: Before you start lifting, take the time to plan the lift and make sure you have the right equipment and personnel.

- Inspect the equipment: Before you start lifting, make sure that the crane, slings, and other equipment are in good condition.

- Secure the load: Make sure that the load is properly secured to the slings before lifting it.

- Lift the load slowly: Lift the load slowly and smoothly to avoid damaging the load or the equipment.

- Stay clear of the load: Stay clear of the load when it is being lifted or lowered.

8. What are the different types of gantry crane accidents and how can they be prevented?

- Crane collapse: Crane collapse can be caused by a number of factors, including overloading, improper maintenance, and wind. To prevent crane collapse, it is important to make sure that the crane is properly designed and maintained and that it is not overloaded.

- Load fall: Load fall can be caused by a number of factors, including improper rigging, loose slings, and sudden movements of the crane. To prevent load fall, it is important to make sure that the load is properly rigged and secured and that the crane is operated smoothly.

- Contact with electrical wires: Contact with electrical wires can be caused by a number of factors, including improper crane operation and inadequate training. To prevent contact with electrical wires, it is important to make sure that the crane is operated by a qualified operator and that the crane is equipped with proper safety devices.

9. What are the different types of gantry crane inspections and how often should they be performed?

- Daily inspection: Daily inspections are performed by the crane operator before each shift. These inspections are visual inspections and are used to identify any obvious signs of damage or wear.

- Monthly inspection: Monthly inspections are performed by a qualified inspector. These inspections are more thorough than daily inspections and are used to identify any potential problems with the crane.

- Annual inspection: Annual inspections are performed by a qualified inspector. These inspections are the most thorough type of inspection and are used to identify any major problems with the crane.

10. What are the different types of gantry crane maintenance and how often should they be performed?

- Preventive maintenance: Preventive maintenance is performed on a regular basis to prevent problems from developing. Preventive maintenance tasks include lubricating the crane, inspecting the crane for signs of wear, and testing the crane’s safety devices.

- Corrective maintenance: Corrective maintenance is performed to fix problems that have already developed. Corrective maintenance tasks include repairing damaged parts, replacing worn parts, and adjusting the crane.

- Emergency maintenance: Emergency maintenance is performed to fix problems that pose an immediate danger. Emergency maintenance tasks include repairing broken parts, replacing damaged parts, and adjusting the crane.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gantry Rigger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gantry Rigger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gantry riggers are responsible for the safe and efficient operation of gantry cranes. They must be able to identify and mitigate hazards, and they must be able to work independently and as part of a team.

1. Operate Gantry Cranes

Gantry riggers must be able to safely and efficiently operate gantry cranes. This includes being able to control the crane’s movement, hoisting and lowering loads, and swinging the crane.

- Control the crane’s movement using joysticks or levers.

- Hoist and lower loads using the crane’s winch.

- Swing the crane to position loads.

2. Inspect and Maintain Cranes

Gantry riggers must be able to inspect and maintain gantry cranes. This includes being able to identify potential hazards, and being able to make repairs and adjustments.

- Inspect cranes for damage or wear.

- Make repairs and adjustments to cranes.

- Lubricate cranes.

3. Rigging Loads

Gantry riggers must be able to rig loads for lifting. This includes being able to select the correct rigging equipment, and being able to safely attach the rigging to the load.

- Select the correct rigging equipment for the load.

- Safely attach the rigging to the load.

- Lift the load and position it.

4. Work Safely

Gantry riggers must be able to work safely. This includes being able to identify and mitigate hazards, and being able to follow safety procedures.

- Identify and mitigate hazards.

- Follow safety procedures.

- Wear appropriate safety gear.

Interview Tips

Preparing for a gantry rigger interview can be daunting, but there are a few things you can do to improve your chances of success. Here are a few tips:

1. Research the Company and the Position

Take the time to learn about the company you’re applying to and the specific position you’re interested in. This will help you answer questions intelligently and show that you’re genuinely interested in the opportunity.

- Visit the company’s website.

- Read articles about the company.

- Talk to people who work for the company.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and smoothly.

- Use the STAR method to answer behavioral questions.

- Tailor your answers to the specific job you’re applying for.

- Practice your answers out loud.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as a gantry rigger. Be prepared to talk about your skills and qualifications, and be able to provide specific examples of your work.

- Highlight your experience operating gantry cranes.

- Describe your experience inspecting and maintaining cranes.

- Provide examples of your rigging experience.

4. Be Enthusiastic and Professional

The interviewer will be looking for someone who is enthusiastic about the job and who is professional in their demeanor. Be sure to make a good impression by being friendly, respectful, and well-dressed.

- Make eye contact with the interviewer.

- Smile and be friendly.

- Dress professionally.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gantry Rigger interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!