Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Garment Form Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

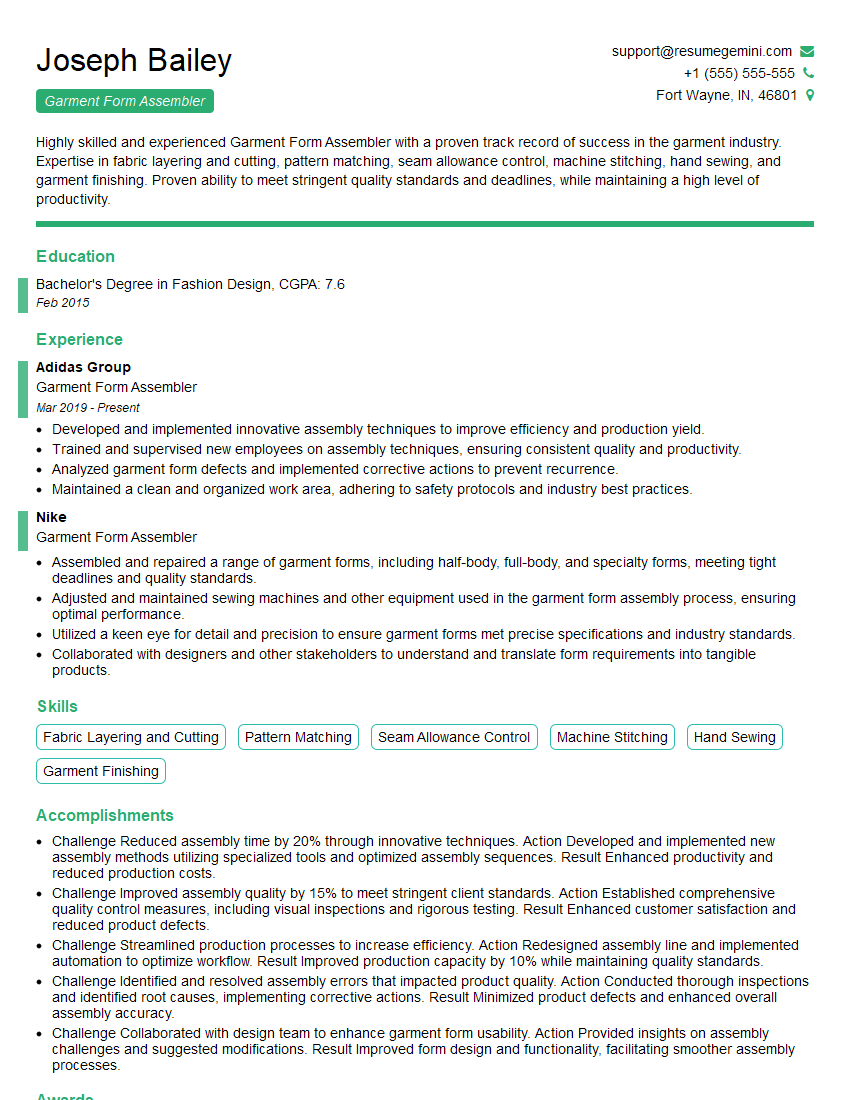

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Garment Form Assembler

1. What are the responsibilities of a Garment Form Assembler?

As a Garment Form Assembler, I am responsible for assembling and maintaining garment forms used in the production of clothing. My duties include:

- Assembling garment forms according to specifications, ensuring accuracy and precision.

- Maintaining and repairing garment forms to extend their lifespan and ensure optimal functionality.

- Inspecting garment forms for defects, identifying issues, and implementing solutions.

- Collaborating with other team members to ensure the smooth flow of production processes.

- Adhering to established quality standards and safety protocols in all aspects of my work.

2. What types of materials are used in the construction of garment forms?

Types of Materials

- Wood: Durable and versatile, used for creating frames and supports.

- Metal: Lightweight and strong, used for creating adjustable joints and mechanisms.

- Foam: Provides padding and shape, used to create body contours.

- Fabric: Covers the form, providing a smooth surface and desired aesthetics.

Additional Materials

- Adhesives: Used to bond materials together securely.

- Hardware: Nuts, bolts, and screws for assembly and adjustments.

- Upholstery materials: Batting, dacron, and other materials for padding and shaping.

3. Describe the different types of garment forms and their uses.

- Full-body forms: Simulate the human body, used for creating entire garments.

- Half-body forms: Represent half of the body, used for creating tops or bottoms.

- Specialty forms: Designed for specific body parts, such as hands, feet, or hats.

- Adjustable forms: Allow for adjustments in size and shape to accommodate different body measurements.

- Dress forms: Used specifically for draping and designing garments.

4. What are the key measurements that need to be taken accurately when assembling a garment form?

- Shoulder width: Distance between the shoulder points.

- Bust circumference: Around the fullest part of the bust.

- Waist circumference: Around the narrowest part of the waist.

- Hip circumference: Around the fullest part of the hips.

- Height: From the top of the head to the floor.

- Arm length: From the shoulder point to the wrist.

- Leg length: From the hip joint to the ankle.

5. What are some common challenges faced when assembling garment forms?

- Ensuring accurate measurements: Precision is crucial to create forms that accurately represent the human body.

- Assembling complex joints: Garment forms often have adjustable joints that require careful assembly for smooth operation.

- Maintaining form stability: Forms must be sturdy and stable to withstand handling and use in various design processes.

- Addressing material variations: Different materials, such as wood and metal, may require specialized techniques and tools for assembly.

- Adhering to quality standards: Garment forms must meet specific quality requirements to ensure their durability and functionality.

6. How do you ensure the quality of garment forms before they are released for use?

- Thorough inspection: Checking for any defects, misalignments, or damage.

- Measurement verification: Confirming that all measurements meet specifications.

- Test assembly: Assembling and disassembling the form to ensure smooth operation.

- Functionality evaluation: Testing adjustable joints and mechanisms for proper movement.

- Documentation review: Verifying that assembly instructions and quality control records are complete and accurate.

7. What is the importance of proper maintenance and repair of garment forms?

- Extends lifespan: Regular maintenance helps preserve the condition and longevity of garment forms.

- Ensures accuracy: Proper repairs address any issues that may affect the accuracy of measurements and shape.

- Improves functionality: Maintaining and repairing adjustable joints and mechanisms ensures smooth operation during use.

- Enhances safety: Addressing any stability or structural issues prevents potential accidents.

- Reduces downtime: Prompt repairs minimize disruptions to production processes.

8. Describe your experience in using different tools and equipment for garment form assembly.

- Hand tools: Screwdrivers, wrenches, pliers, hammers.

- Power tools: Drills, saws, sanders.

- Measuring instruments: Tape measures, calipers, rulers.

- Assembly jigs and fixtures: To ensure accurate alignment and positioning.

- Upholstery equipment: Staplers, batting needles, sewing machines.

9. How do you stay updated on the latest techniques and best practices in garment form assembly?

- Attend industry workshops and seminars: Engage with experts and learn about new developments.

- Subscribe to trade publications and online resources: Stay informed about industry trends and best practices.

- Network with other professionals: Exchange knowledge and experiences with fellow garment form assemblers.

- Research and explore new materials and technologies: Stay abreast of advancements in materials and techniques.

- Seek feedback from designers and production teams: Understand their needs and incorporate their insights into assembly processes.

10. How do you manage your time effectively when working on multiple garment form assemblies?

- Prioritize tasks: Identify the most important forms and allocate time accordingly.

- Plan and schedule: Create a realistic schedule to manage multiple projects simultaneously.

- Break down tasks: Divide complex assemblies into smaller, manageable steps.

- Delegate responsibilities: If possible, assign specific tasks to other team members to distribute workload.

- Use time management tools: Utilize calendars, task lists, and project management software to stay organized.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Garment Form Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Garment Form Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Garment Form Assemblers are responsible for assembling garment forms, which are used to display clothing in retail stores and showrooms. They work in a factory setting, using a variety of tools and equipment to create the forms.

1. Assemble garment forms

Garment Form Assemblers use a variety of tools and equipment to assemble garment forms. These tools may include screwdrivers, hammers, drills, and saws. They must be able to follow instructions and work accurately and efficiently.

- Follow instructions to assemble garment forms

- Use a variety of tools and equipment to assemble forms

2. Inspect garment forms

Garment Form Assemblers must inspect garment forms for defects before they are shipped to retail stores. They must be able to identify any flaws in the form, such as cracks, dents, or scratches.

- Inspect garment forms for defects

- Identify any flaws in the form

3. Package and ship garment forms

Garment Form Assemblers package and ship garment forms to retail stores. They must be able to pack the forms securely so that they are not damaged during shipping.

- Package garment forms securely

- Ship garment forms to retail stores

4. Maintain a clean and organized work area

Garment Form Assemblers must maintain a clean and organized work area. This helps to ensure that the forms are assembled correctly and that the workplace is safe.

- Maintain a clean and organized work area

- Ensure that the workplace is safe

Interview Tips

Here are some tips to help you ace your interview for a Garment Form Assembler position:

1. Research the company

Before you go to your interview, take some time to research the company. This will help you understand the company’s culture and values, and it will also show the interviewer that you are interested in the position.

- Visit the company’s website

- Read articles about the company

- Talk to people who work for the company

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Practice answering common interview questions

- Deliver your answers confidently and clearly

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in assembling garment forms. Be prepared to talk about your skills and experience, and be sure to highlight any relevant experience that you have.

- Be prepared to talk about your experience

- Highlight any relevant experience that you have

4. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing jewelry or clothing that is too revealing.

- Dress professionally for your interview

- Wear clean, pressed clothes and shoes

5. Be on time

Punctuality is important, so be sure to arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Be on time for your interview

- Show the interviewer that you are respectful of their time

6. Be confident

Confidence is key in any interview. Be confident in your abilities and your experience, and be sure to make eye contact with the interviewer. This will show the interviewer that you are confident in your ability to do the job.

- Be confident in your abilities and your experience

- Make eye contact with the interviewer

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Garment Form Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.