Are you gearing up for an interview for a Garment Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Garment Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

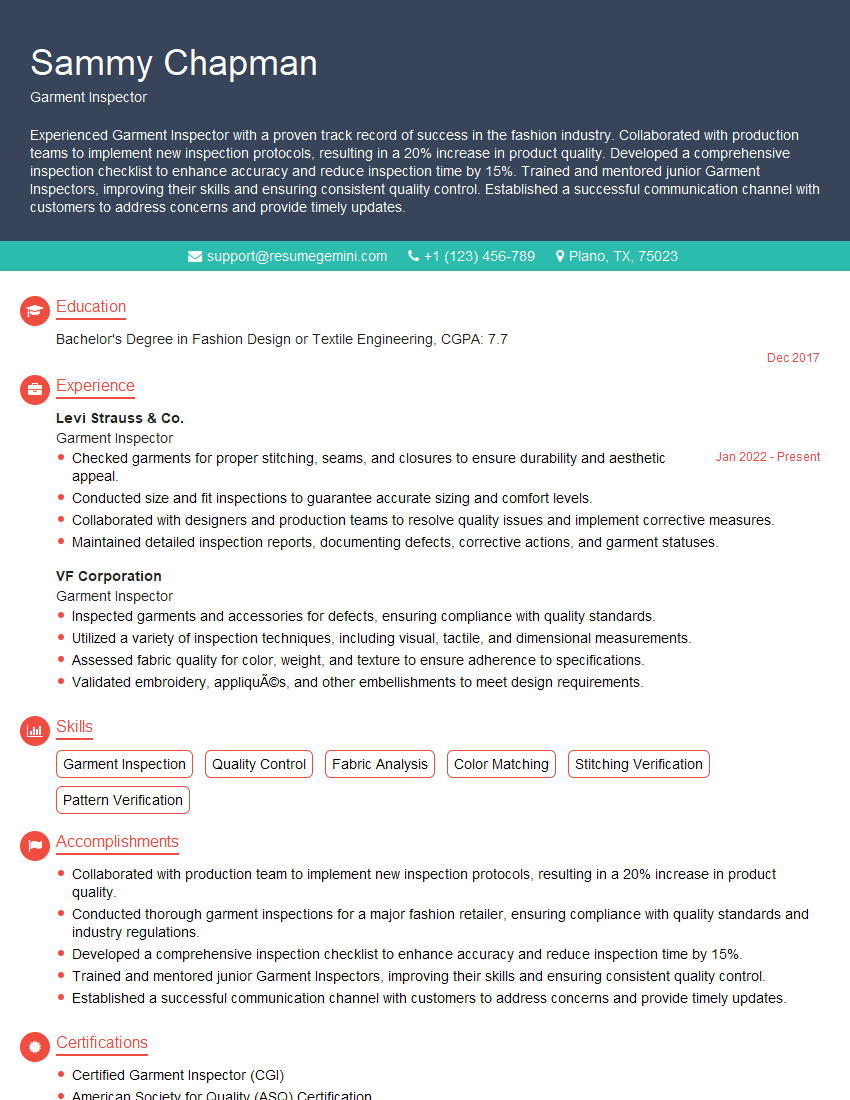

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Garment Inspector

1. Explain the inspection process you follow for garments?

The garment inspection process I follow involves several key steps to ensure the quality and compliance of the garments:

- Pre-production Inspection: Reviewing technical specifications, patterns, and fabric samples to identify potential issues before production begins.

- During Production Inspection (DPI): Conducting random inspections at the factory during production to monitor quality, adherence to specifications, and production progress.

- Final Random Inspection (FRI): Selecting a sample from the finished goods and thoroughly inspecting each garment for defects, workmanship, and compliance with the agreed-upon standards.

- Container Loading Inspection: Verifying the packing and loading of garments into containers to ensure proper handling and no damage during transit.

2. What are the common defects you look for in garments?

Major Defects

- Holes, tears, or snags in fabric

- Broken or missing buttons, zippers, or other closures

- Uneven seams or stitching defects

- Incorrect size or shape

- Fabric discoloration or fading

Minor Defects

- Loose threads or raw edges

- Misaligned prints or embroidery

- Wrinkles or creases that cannot be removed

- Slight variations in color or texture

3. How do you handle garments with critical defects?

When I identify garments with critical defects, I follow a standardized process to ensure proper handling and resolution:

- Immediate Segregation: Isolating the defective garments to prevent them from being shipped.

- Defect Classification: Categorizing the defects based on their severity and potential impact on the garment’s functionality or aesthetics.

- Root Cause Analysis: Investigating the source of the defect to determine if it’s a production issue, design flaw, or material problem.

- Corrective Action Communication: Reporting the defects and root causes to the relevant parties (factory, buyer, etc.) and recommending corrective actions.

- Re-inspection: Once corrective actions are implemented, re-inspecting the affected garments to ensure compliance before release.

4. What is your approach to inspecting garments for compliance with AQL standards?

To ensure compliance with AQL (Acceptable Quality Level) standards, I employ a systematic sampling and inspection methodology:

- Sampling Plan Selection: Determining the appropriate sampling plan based on the production lot size and AQL requirements.

- Random Sample Selection: Selecting a random sample from the lot using statistical methods to ensure a representative sample.

- Thorough Inspection: Inspecting each garment in the sample according to the specified inspection criteria.

- Defect Counting: Recording the number of defects found in the sample.

- Acceptance or Rejection: Comparing the number of defects to the AQL tolerance level to determine whether the lot is accepted or rejected.

5. How do you maintain objectivity and consistency in your inspections?

To ensure objectivity and consistency in my inspections, I adhere to the following principles:

- Established Inspection Criteria: Using well-defined and standardized inspection criteria that are communicated to all parties involved.

- Independent Inspection: Conducting inspections independently without bias or influence from external sources.

- Regular Training and Calibration: Participating in regular training and calibration exercises to stay updated on industry best practices and maintain accuracy.

- Use of Inspection Tools: Employing appropriate inspection tools, such as magnifying glasses, measuring tapes, and light boxes, to aid in thorough and precise inspections.

- Documentation and Record-Keeping: Maintaining detailed records of inspections, including findings, corrective actions, and communication with all stakeholders.

6. Describe your experience in working with different types of fabrics and garments.

Throughout my career, I have gained extensive experience in inspecting a wide range of fabrics and garments, including:

- Natural fibers: Cotton, linen, silk, wool

- Synthetic fibers: Polyester, nylon, spandex, acrylic

- Blended fabrics: Combinations of natural and synthetic fibers

- Garments: T-shirts, shirts, pants, dresses, jackets, sweaters

- Special fabrics: Leather, denim, lace, embroidery

7. How do you stay up-to-date with industry standards and regulations?

To remain current with industry standards and regulations, I engage in several ongoing practices:

- Professional Development: Attending industry conferences, workshops, and webinars to learn about the latest inspection techniques and quality control practices.

- Industry Publications: Reading trade journals, magazines, and online resources to stay informed about best practices and emerging trends.

- Networking and Collaboration: Interacting with other garment inspectors, quality control professionals, and industry experts to exchange knowledge and experiences.

- Certification and Accreditation: Obtaining certifications or accreditations from recognized organizations to demonstrate my competence and commitment to quality.

8. How do you handle disagreements or challenges during inspections?

When faced with disagreements or challenges during inspections, I approach them with professionalism and diplomacy:

- Open Communication: Engaging in respectful and clear communication with all parties involved to understand their perspectives and concerns.

- Objective Evidence: Presenting objective evidence and data to support my findings and assessments.

- Collaborative Problem-Solving: Seeking collaborative solutions that address the concerns while maintaining quality standards.

- Escalation Management: If necessary, escalating the issue to a higher authority for guidance or resolution.

9. Can you describe a situation where you identified a potential quality issue early in the production process and how you handled it?

In a recent inspection, I noticed a slight variation in the color of a fabric being used in a particular garment style. I suspected this could lead to potential quality problems if not addressed promptly:

- Early Detection: I immediately flagged the issue to the factory management and the buyer.

- Root Cause Analysis: We conducted an investigation to determine the cause of the color variation.

- Corrective Action: Based on the analysis, we identified a problem with the dyeing process and implemented corrective measures to ensure consistency.

- Re-inspection: After implementing the corrective actions, I re-inspected the affected garments to verify the issue had been resolved.

10. How do you prioritize your workload when faced with multiple inspection tasks?

When managing multiple inspection tasks, I prioritize my workload based on the following factors:

- Criticality: Prioritizing inspections based on the potential impact of defects on garment quality, compliance, or customer satisfaction.

- Time Sensitivity: Considering the time constraints and deadlines associated with each inspection task.

- Resource Availability: Assessing the availability of necessary resources, such as inspection tools, lighting, and support staff.

- Communication: Coordinating with relevant parties to ensure clear expectations and timely delivery of inspection reports.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Garment Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Garment Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Garment Inspectors are responsible for ensuring that garments meet quality standards. They inspect garments for defects and make sure that they are constructed correctly.

1. Inspect garments for defects

Garment Inspectors need to be able to identify a wide range of defects, including errors in stitching, fabric flaws, and color inconsistencies. They may also need to check for compliance with safety regulations.

- Examine garments for defects such as incorrect stitching, missing buttons, or uneven seams.

- Check fabric for tears, stains, or holes.

- Verify that garments meet quality standards.

2. Ensure garments are constructed correctly

Inspectors need to make sure that garments are constructed according to specifications. This includes checking the size, fit, and finish of the garment.

- Check garment measurements against technical specifications.

- Ensure that garments are sewn together correctly.

- Inspect finished garments for any defects or inconsistencies.

3. Maintain quality records

Inspectors need to keep records of their inspections. This includes noting any defects they find and the garments they inspected.

- Document inspection results.

- Maintain records of all inspected garments.

- Report any defects or quality issues to the supervisor.

4. Communicate with supervisors and production staff

Inspectors need to communicate with supervisors and production staff to ensure that garments are produced according to standards. They may need to report defects, make suggestions for improvements, or provide feedback on production processes.

- Communicate inspection results to supervisors and production staff.

- Provide feedback on production processes.

- Collaborate with supervisors to improve quality standards.

Interview Tips

To prepare for your interview for a Garment Inspector position, there are a few things you can do to increase your chances of success.

1. Research the company and the position

It is important to research the company you are applying to and the specific position you are interested in. This will help you understand the company’s culture, values, and expectations for the role.

- Visit the company’s website.

- Read about the company in industry publications.

- Talk to people who work for the company.

2. Prepare your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. It is important to prepare your answers to these questions in advance so that you can deliver them confidently and succinctly.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with garment inspection?

- How do you stay up-to-date on the latest industry trends?

3. Practice your interviewing skills

It is important to practice your interviewing skills so that you can feel confident and prepared on the day of your interview. You can practice with a friend, family member, or career counselor.

- Practice answering common interview questions.

- Role-play different interview scenarios.

- Get feedback on your interviewing skills.

4. Be prepared to ask questions

Asking questions at the end of your interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the role and the company culture.

- Ask about the company’s growth plans.

- Ask about the company’s culture.

- Ask about the specific responsibilities of the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Garment Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!